Gas premixing porous-medium combustor achieving axial and radial stable combustion

A porous medium, burner technology, applied in gas fuel burners, burners, burners, etc., can solve problems such as cracking and flameout, uneven structure, increased pollutant emissions, etc., to widen the adjustment range and improve uniformity. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

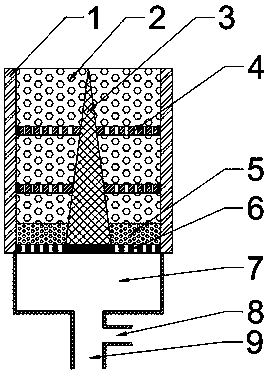

[0019] according to figure 1 The specific structure of the present invention will be described in detail. The present invention adopts the way of premixed combustion of gas and air, including insulation layer, porous medium in combustion zone, stable combustion body, stable combustion perforated plate, porous medium in anti-tempering zone, equalizer plate, premixing chamber, gas inlet and air inlet . The gas inlet and the air inlet are connected to the premixing chamber, and the premixing chamber is arranged with a uniform flow plate, a porous medium in the anti-backfire area, a stable combustion porous plate, and a porous medium in the combustion area. The stable combustion body is conical, made of high temperature resistant austenitic steel, and placed at the axis of the burner. The pore diameter of the combustion stabilizing perforated plate gradually decreases outward along the radial direction. The stable combustion perforated plate is made of high temperature resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com