Manufacturing process of quantum dot diffusion plate, and diffusion plate

A technology of quantum dots and diffuser plates is applied in the field of backlight lighting, which can solve the problem that the light guide plate cannot be used with LED lamps, and achieve the effect of improving the color gamut, high color gamut and luminous efficiency of transmitted light, and reducing the harm of blue light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

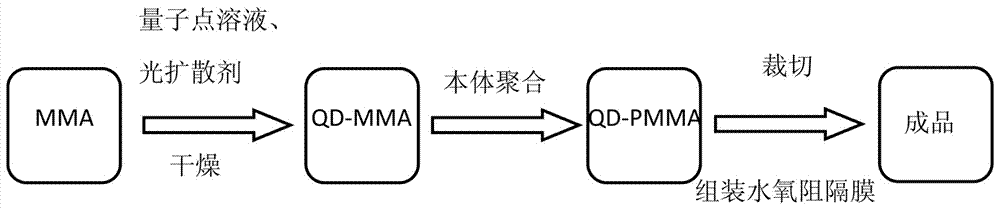

[0071] 1. Weigh a certain amount of methyl methacrylate (MMA), weigh 0.25% of the weight of MMA quantum dots, wherein the ratio of green quantum dots to red quantum dots is 50:1, and weigh 0.5% of the weight of MMA Cyclohexane solution, weigh 0.43% dibenzoyl peroxide (BPO) by weight of MMA, weigh 0.2% light diffusing agent by weight of MMA.

[0072] 2. Dissolve quantum dots in cyclohexane solution, ultrasonically and oscillate to dissolve; add methyl methacrylate (MMA) dropwise to the above mixture, and shake well at the same time to fully disperse the quantum dot solution in MMA to form QD- MMA solution: add the light diffusing agent into the QD-MMA solution, stir and ultrasonically vibrate, so that the light diffusing agent is evenly dispersed in the solution.

[0073] 3. Add dibenzoyl peroxide (BPO) into the prepared solution in 2 and shake it to make it fully dissolved, then add an appropriate amount of anhydrous calcium chloride to remove water and dry, and filter to obta...

Embodiment 2

[0080] 1. Weigh a certain amount of methyl methacrylate (MMA), and weigh quantum dots whose weight is 1.25% of MMA weight, wherein the ratio of green quantum dots to red quantum dots is 50:1, and weigh 1.9% of MMA weight Cyclohexane solution, weigh 0.48% dibenzoyl peroxide (BPO) by weight of MMA, weigh 0.3% light diffusing agent by weight of MMA.

[0081] 2. Dissolve quantum dots in cyclohexane solution, ultrasonically and oscillate to dissolve; add methyl methacrylate (MMA) dropwise to the above mixture, and shake well at the same time to fully disperse the quantum dot solution in MMA to form QD- MMA solution: add the light diffusing agent into the QD-MMA solution, stir and ultrasonically vibrate, so that the light diffusing agent is evenly dispersed in the solution.

[0082] 3. Add dibenzoyl peroxide (BPO) into the prepared solution in 2 and shake it to make it fully dissolved, then add an appropriate amount of anhydrous calcium chloride to remove water and dry, and filter t...

Embodiment 3

[0089] 1. Weigh a certain amount of methyl methacrylate (MMA), and weigh quantum dots whose weight is 1.00% of MMA weight, wherein the ratio of green quantum dots to red quantum dots is 50:1, and weigh 1.2% of MMA weight Cyclohexane solution, weigh 0.44% dibenzoyl peroxide (BPO) by weight of MMA, and weigh 0.4% light diffusing agent by weight of MMA.

[0090] 2. Dissolve quantum dots in cyclohexane solution, ultrasonically and oscillate to dissolve; add methyl methacrylate (MMA) dropwise to the above mixture, and shake well at the same time to fully disperse the quantum dot solution in MMA to form QD- MMA solution: add the light diffusing agent into the QD-MMA solution, stir and ultrasonically vibrate, so that the light diffusing agent is evenly dispersed in the solution.

[0091] 3. Add dibenzoyl peroxide (BPO) into the prepared solution in 2 and shake it to make it fully dissolved, then add an appropriate amount of anhydrous calcium chloride to remove water and dry, and filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com