Shaft-vibration forced mixer

A mixer and shaft vibration technology, which is applied in the fields of cement mortar and asphalt mixture mixers, cement concrete, and cement stabilized soil, can solve the problems of large vibration power loss, effect of effective mixing volume, poor stability and durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

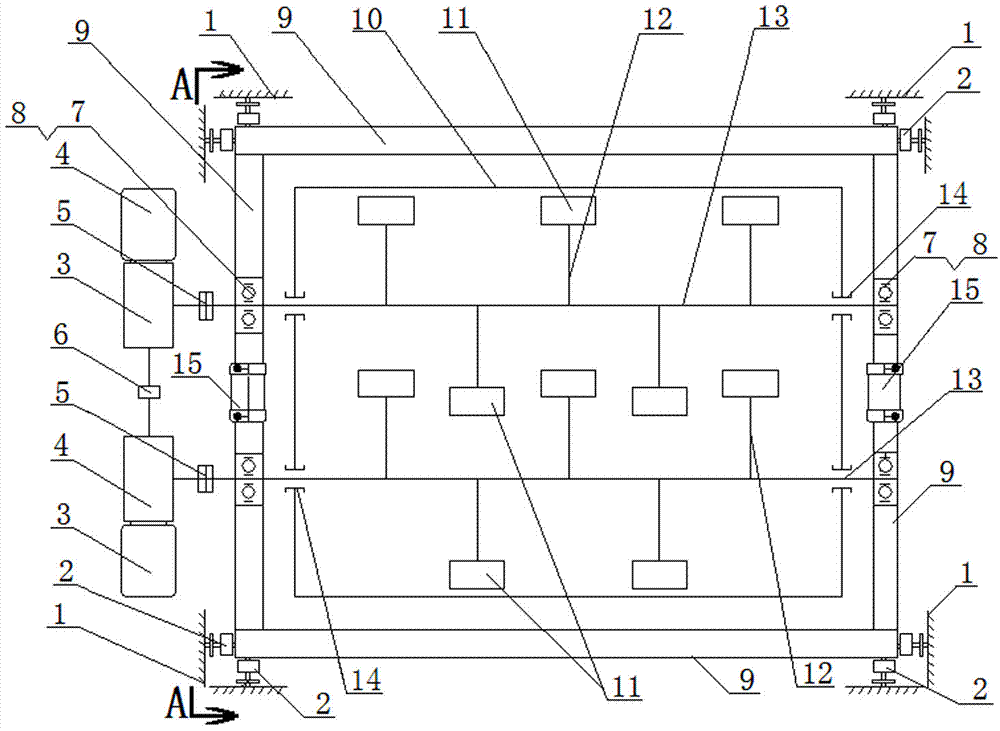

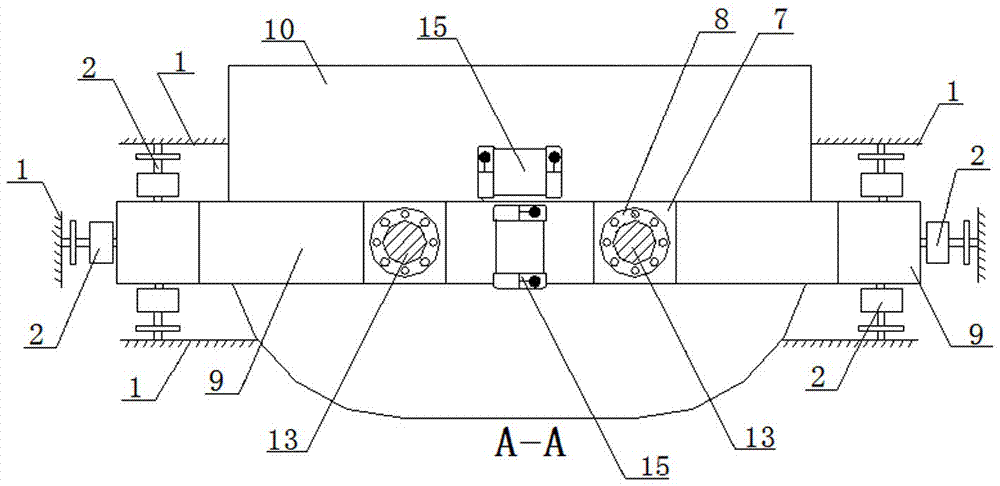

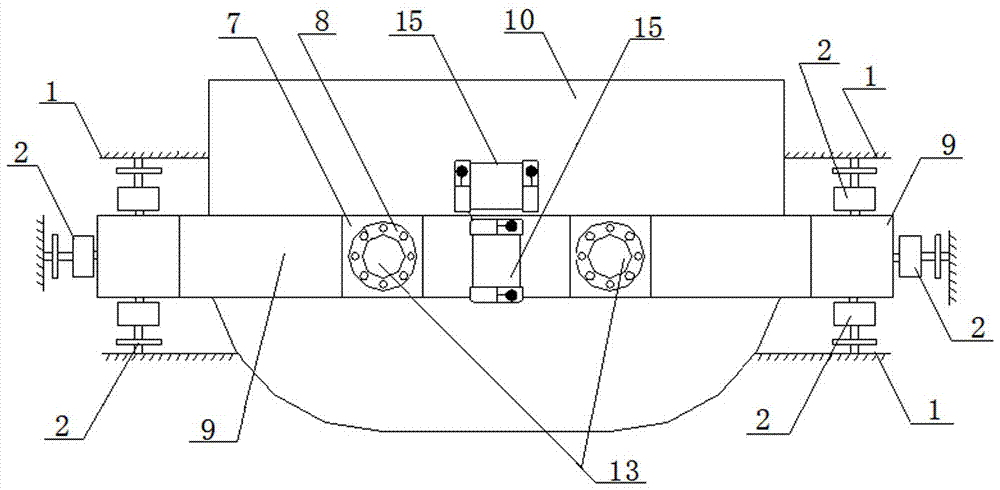

[0040] Figure 4 As shown, it is a top view structure schematic diagram of Embodiment 1 of the present invention, as can be seen from the figure, it is in figure 1 The front and rear beams in the square frame-shaped vibrating frame 9 are omitted on the basis of the above, and the left vibrating beam 16 and the right vibrating beam 17 are connected to the upper, lower, left, right, and outer sides of the two ends of the remaining left vibrating beam 16 and the right vibrating beam 17. with figure 1 The same constitutes a shaft vibrating forced mixer.

Embodiment 2

[0042] Figure 5 Shown, is the top view structural representation of embodiment 2 of the present invention; As can be seen from the figure, it is in Figure 4 On the basis of the left vibrating beam 16 and the buffer 2 connected to its two ends, and the two vertical vibrators 15 arranged on the left vibrating beam 16 are omitted; the bearing 8 at the left end of the two stirring shafts 13 passes through the bearing seat 7 It is fixedly connected with the fixed frame to form a shaft vibration forced mixer.

Embodiment 3

[0044] Image 6 Shown is a top view structural schematic diagram of Embodiment 3 of the present invention, Figure 7 yes Image 6 The enlarged schematic diagram of the right-view structure of ; from the two figures, it can be seen that Figure 4 The left vibrating beam 16 and the right vibrating beam 17 are omitted on the basis of the above; the buffer 2 is arranged on the bottom, left and right sides of the bearing housings 7 at both ends of the two stirring shafts 13 and is positioned and connected with the fixed frame 1, and each bearing housing 7 A vibrator 15 is horizontally arranged on the top of the shaft to form a shaft vibrating forced mixer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com