Preparation method for glass fiber reinforced AS (acrylonitrile-styrene) resin

A technology of resin and glass fiber, applied in the field of preparation of glass fiber reinforced AS resin, can solve the problems of high scrap rate of products and difficult correction of fan blades, and achieve the effect of high strength and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The embodiment of the invention discloses a preparation method of glass fiber reinforced AS resin, including:

[0019] Feed the raw materials into the twin-screw extruder for blending and extrusion;

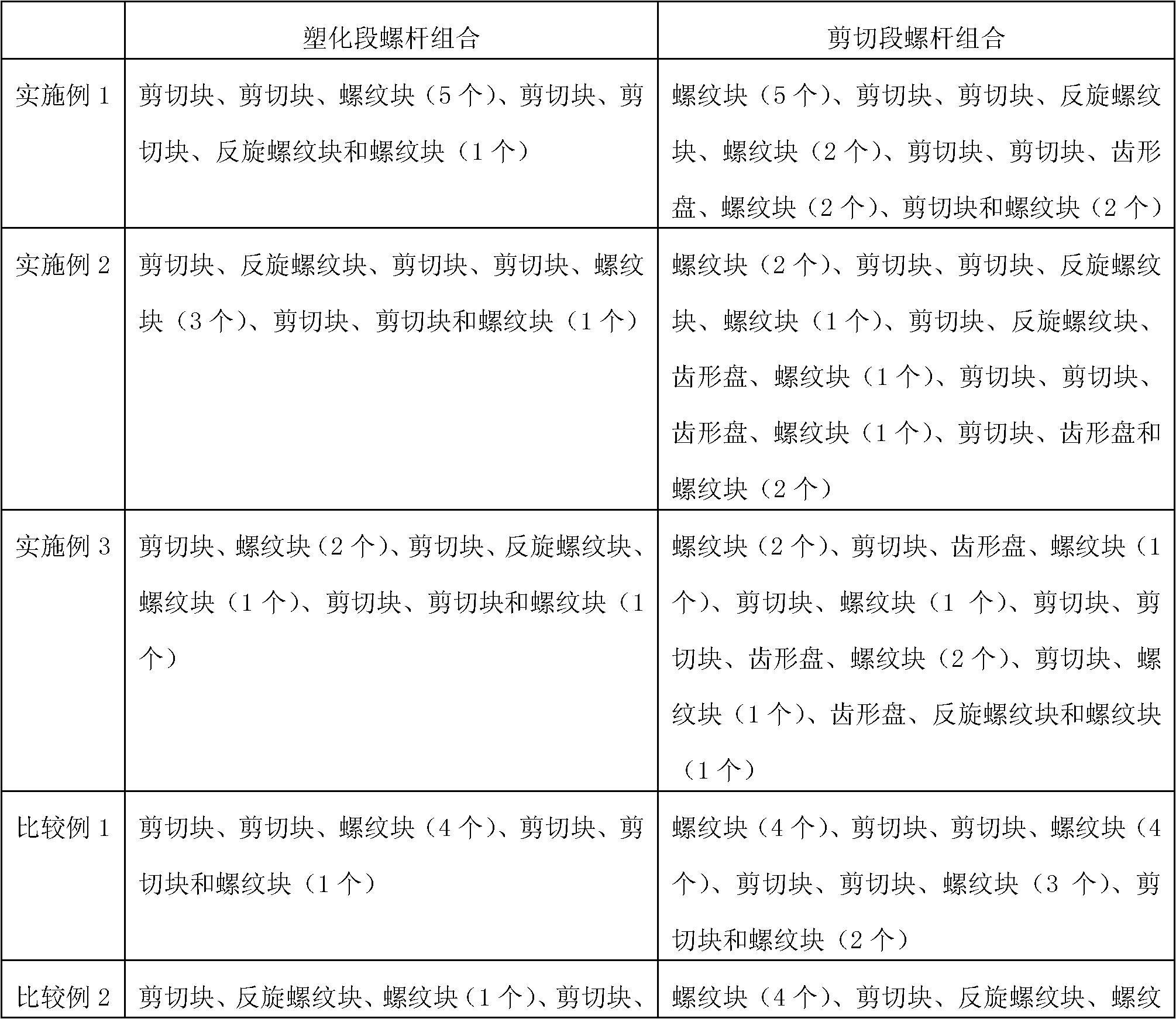

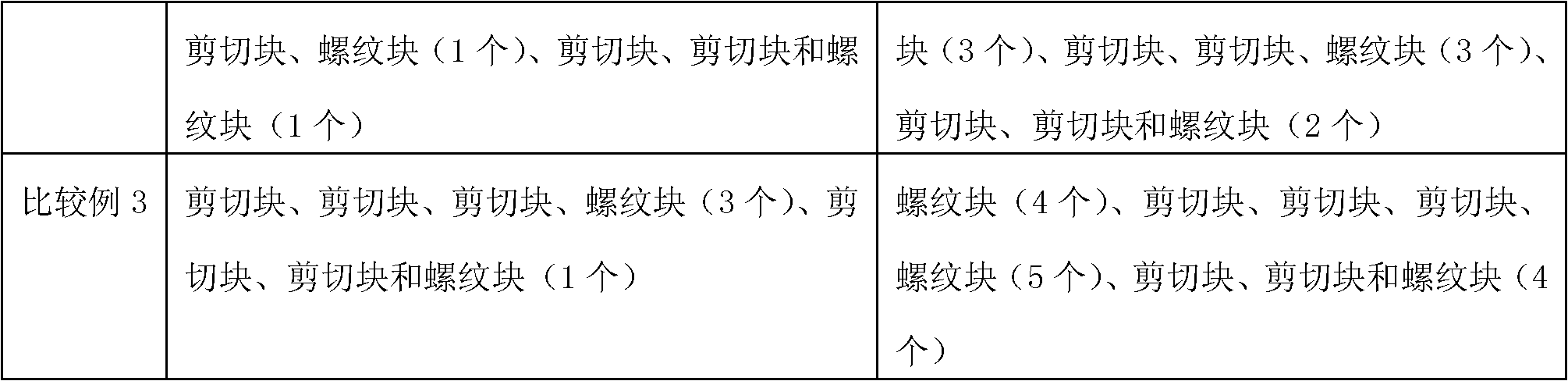

[0020] Among them, the screw combination of the plasticizing section and the shearing section of the twin-screw extruder includes: 9-21 shear blocks, 2 to 4 counter-rotating thread blocks and 1 to 3 toothed disks;

[0021] The raw materials include: 63-86.4wt% AS resin, 13-35wt% glass fiber, 0.1-0.6wt% coupling agent, 0.2-0.6wt% antioxidant and 0.3-0.8wt% lubricant .

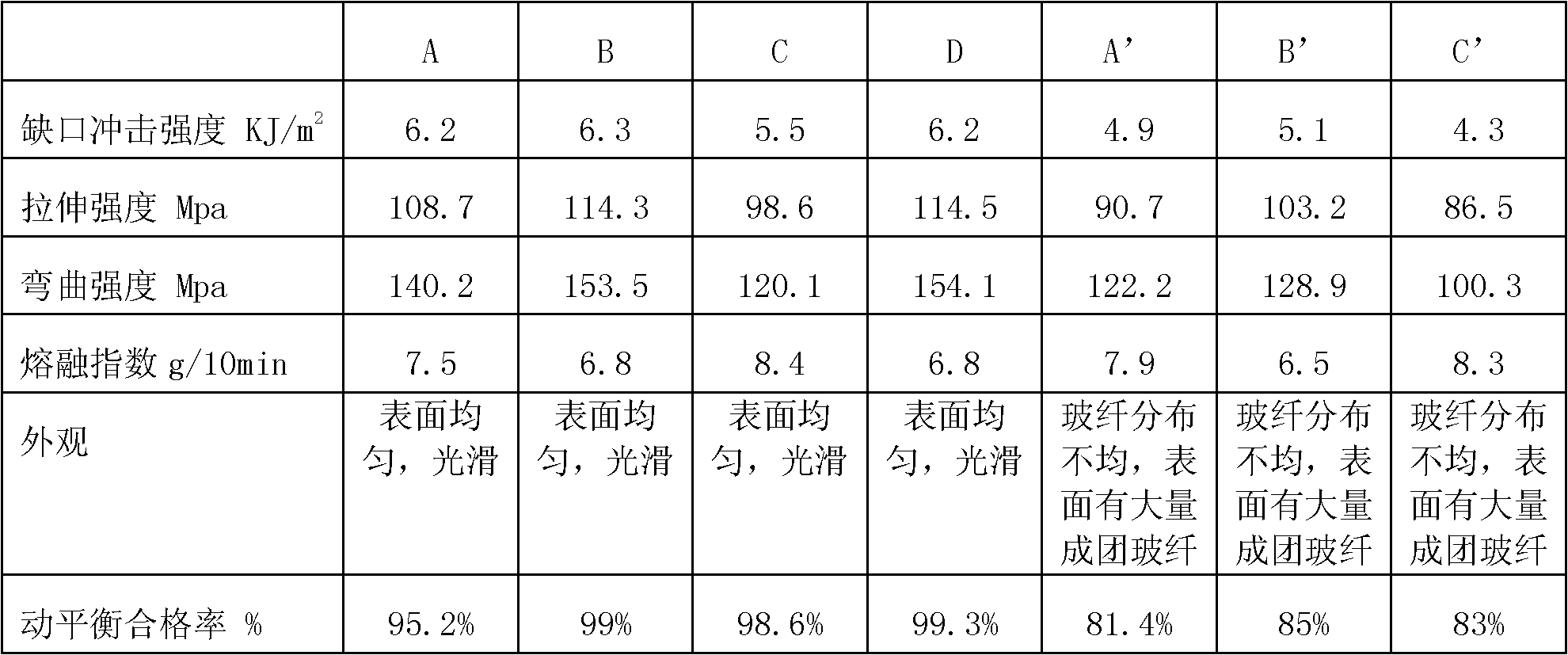

[0022] In order to improve the uniformity of mixing AS resin and glass fiber, the present invention considers strong shearing of AS resin and glass fiber, because if the shearing force is too small, the long glass fiber is difficult to cut completely and cannot be uniformly dispersed in the material. The surface of the product is agglomerated, the appearance is poor, and the density is uneven; but the shearing forc...

Embodiment 1

[0033] Ingredients formula:

[0034] High-strength AS resin: 38.75%

[0035] High fluidity AS resin: 38.75%

[0036] Glass fiber: 20%

[0037] Talc: 1%

[0038] Antioxidant: 0.2% pentaerythritol ester and 0.3% phenyl phosphite antioxidant

[0039] Phthalic acid lubricant: 0.5%

[0040] Silane coupling agent: 0.5%

[0041] Melt and blend the above on a co-rotating twin-screw extruder, set the temperature from the feeding port to the die at 200°C to 240°C, and see Table 1 for the screw combination modes of the plasticizing section and the shearing section.

[0042] The screw speed was 500 rpm, the extrudate was cooled and pelletized, and vacuum dried at 85°C for 4 hours.

Embodiment 2

[0044] Ingredients formula:

[0045] High strength AS resin: 77.5%

[0046] Glass fiber: 20%

[0047] Talc: 1%

[0048] Antioxidant: 0.2% pentaerythritol ester and 0.3% phenyl phosphite antioxidant

[0049] Phthalic acid lubricant: 0.5%

[0050] Silane coupling agent: 0.5%

[0051] The preparation method of the glass fiber reinforced AS resin in this example is the same as that in Example 1, except that the screw combination mode of the plasticizing section and the shearing section is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com