Plant hot-mix recycled asphalt mixture and preparation method thereof

An asphalt mixture and thermal regeneration technology, applied in the field of road engineering, can solve the problem of difficulty in increasing the content of waste materials, and achieve the effects of good texture, good fusion and uniform fusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also provides a method for preparing the above-mentioned plant-mixed hot recycled asphalt mixture, comprising the following steps:

[0019] A. Put the old milling material, heavy aromatics and acrylamide into the preheating cylinder, heat it to 80-110°C, transfer it to the mixing tank, and mix it at 150-170°C for 15-30s;

[0020] B. Add new aggregate and half of new asphalt, heat to 180-200°C, and mix for 15-30s;

[0021] C. Add the other half of new asphalt, mineral powder and regenerant, heat to 180-200°C, mix for 30-60s, and take out the pot at 140-170°C to obtain factory-mixed hot recycled asphalt mixture.

[0022] In the plant-mixed heat-recycled mixture of the present invention, the original asphalt pavement is layered and milled to recover, crushed and processed into a suitable particle size, and the plant-mixed heat regeneration is carried out by adding new asphalt, regeneration agent, and new aggregates. First of all, the old milling mate...

Embodiment

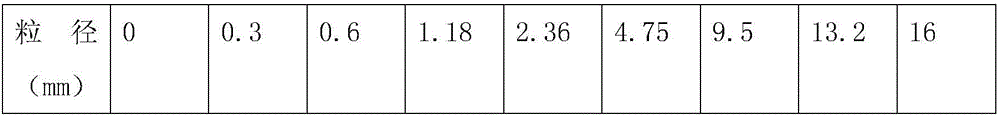

[0026] The old milling material used in the experiment is the material of the same source and the same particle size. First, the old material is sampled, and then the sample is subjected to an extraction test. The asphalt content of the milling old material is 11.21%. A sieving test was carried out on the old aggregate obtained from the extraction test, and the test results are shown in Table 1. The old asphalt after the extraction test was recovered by rotary evaporation method, and the performance index test was carried out. The test results are shown in Table 2.

[0027] Table 1 Collection and distribution of old aggregate ore

[0028]

[0029]

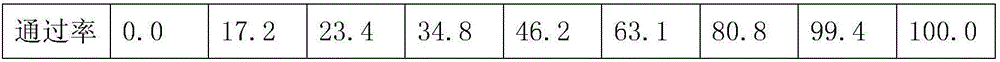

[0030] Table 2 Determination of properties of old milling materials

[0031]

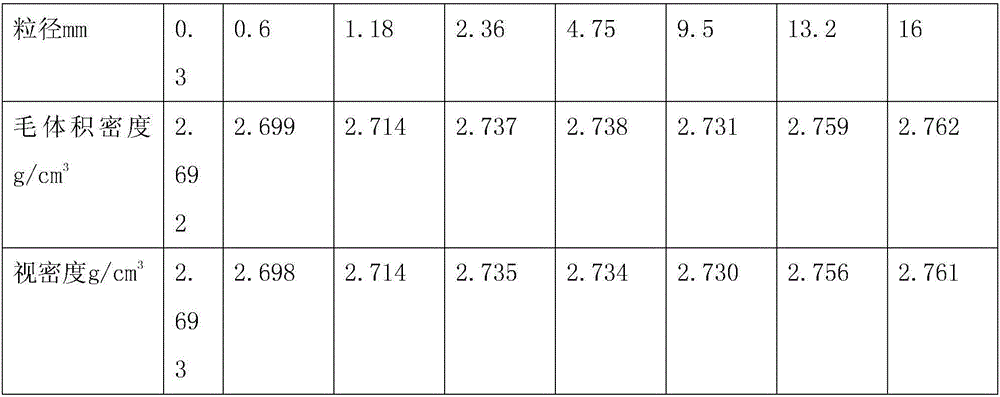

[0032] The new aggregate is limestone, and the mineral powder is limestone mineral powder. The relative density of the new aggregate was tested, and the test results are shown in Table 3.

[0033] Table 3 Experimental results of relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com