Soft-packed lithium battery lead metal strip and insulation sheet fusion technique

A technology of soft-pack lithium batteries and metal strips, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of lithium battery leakage, long production time, inflation, etc., to solve sealing problems and improve production The effect of quality and sealing guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

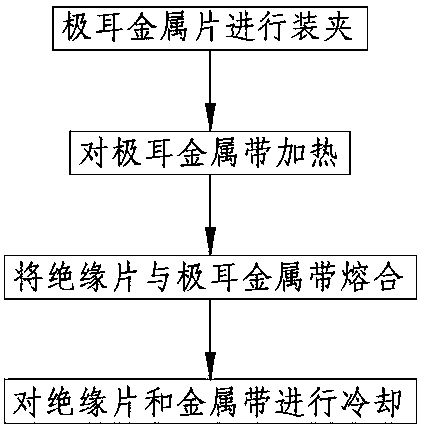

[0015] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated: please refer to figure 1 , a process for fusing tab metal strips and insulating sheets of soft-packed lithium batteries, placing the tab metal strips to be processed on a heating fixture for fixing.

[0016] The tab metal strip is heated by a heating device, and the heating device simultaneously heats both ends and both sides of the tab metal strip. By heating both ends and both sides at the same time, the tab metal strip is heated evenly and reaches the required temperature faster. The belt heating time is 100 to 150 seconds. Through slow heating, the temperature of each part of the tab metal can be raised evenly. Said heating temperature is 90 to 120 degrees centigrade, and this temperature can soften the insulating sheet and fuse the tab metal sheet. The heating method of the heating device is high-frequency induction heating. This he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com