Machine for spinning nano-fiber for production of non-woven cloth

A non-woven fabric and nanofiber technology, applied in non-woven fabrics, fiber processing, textiles and papermaking, etc., can solve the problems of changing the electric field distribution, affecting the use of products, and affecting the spinning process, so as to avoid electric field interference and prevent Unstable, stable spinning jet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

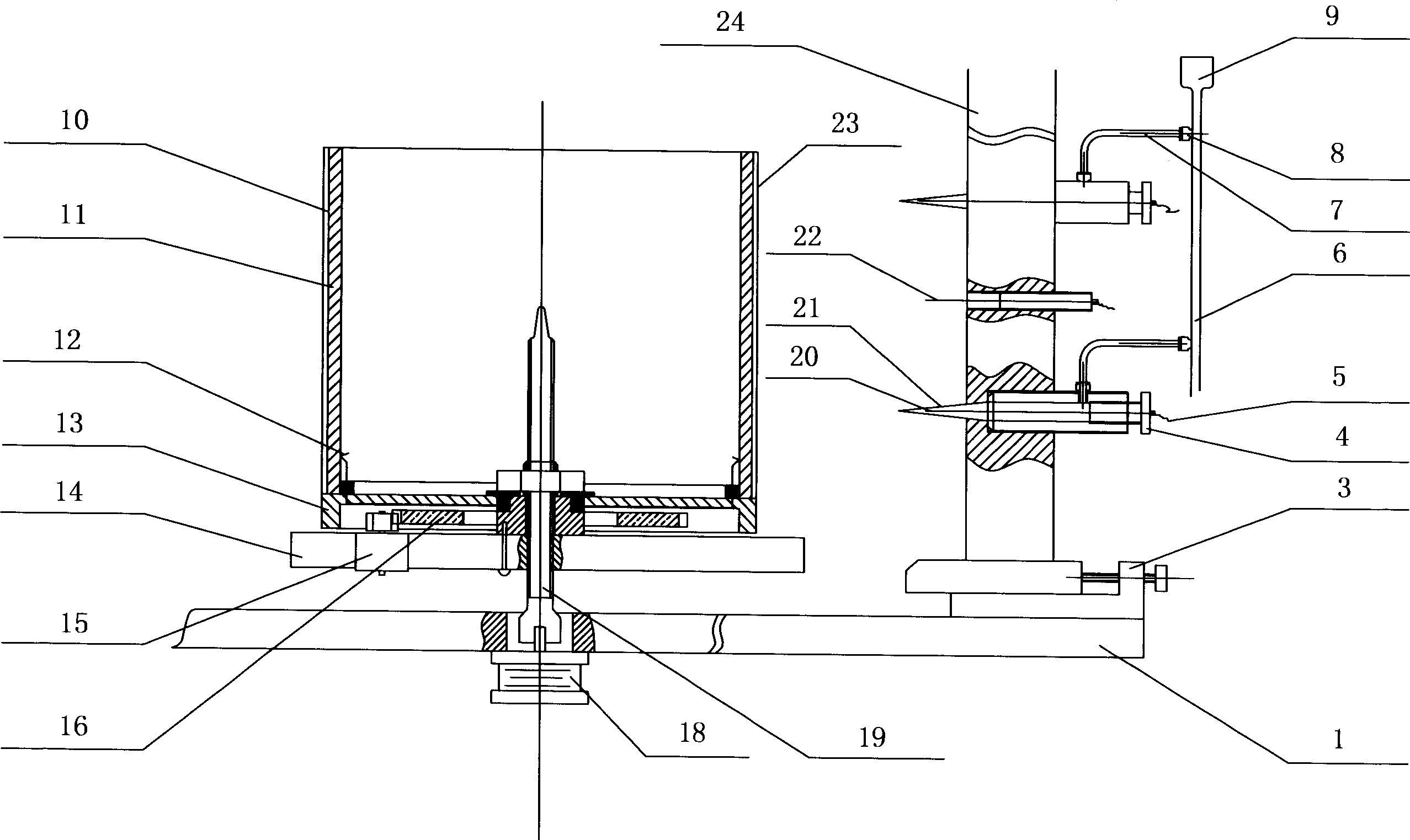

[0035] Embodiment one: see attached figure 1As shown, a nanofiber nonwoven spinning machine is mainly composed of a high-voltage power supply device, a spinning solution storage tank, a receiving device, and at least one set of spinning components. The spinning solution storage tank is passed through a pump and a pipeline It communicates with the spinning tube in the spinning assembly, and the outlet of the spinning solution storage tank is provided with a primary flow regulator 9, and the pipeline includes a catheter 6 connected with the spinning solution storage tank, and connecting each spinning solution respectively. The shunt tube 7 of the silk tube, the catheter tube 6 is provided with a plurality of quick joints 8, the end of the shunt tube 7 is provided with a connection structure that cooperates with the quick joints 8, and communicates with the catheter tube 6 through the quick joints 8 . Among them, the high-voltage power supply device at least includes high-voltag...

Embodiment 2

[0037] Embodiment 2: The spinning machine of Embodiment 1 is used to prepare nano-regenerated spider ovum silk fiber nonwoven fabric.

[0038] The spider ova silk fibers were dissolved in hexafluoroisopropanol to obtain a regenerated spider ova silk solution with a concentration of 1.0 wt%. Each spinning assembly uses four spinning tubes, two groups of spinning components are arranged opposite to each other with the axis of the receiving cylinder as the axis of symmetry, the distance between adjacent spinning tubes is 5 cm, and the diameter of the receiving cylinder is 10 cm . The distance C-SD between the spinneret and the receiving metal net is 12 cm and 8 cm respectively, and the electrospinning is carried out under the condition of a voltage of 16KV, and the nano-regenerated spider egg-coated silk fibers shown in the figure are obtained, and they are uniformly interlaced. network to form a nonwoven fabric.

[0039] attached figure 2 It is the fabric obtained when the d...

Embodiment 3

[0041] Embodiment 3: The spinning machine of Embodiment 1 is used to prepare nanometer nylon 6 fiber nonwoven fabric.

[0042] Nylon 6 slices were dissolved in 88% formic acid to obtain a nylon 6 solution with a concentration of 12 wt%. Each spinning assembly uses seven spinning tubes, four groups of spinning components are arranged symmetrically with the axis of the receiving cylinder, the distance between adjacent spinning tubes is 3 cm, and the diameter of the receiving cylinder is 10 cm . Electrospinning is carried out when the distance C-SD and the voltage between the spinneret and the receiving metal mesh are 15 cm and 22.5KV respectively, and the obtained Figure 4 The shown nano nylon 6 fibers have an average diameter of 77.55±15.75nm. Electrospinning is carried out under the condition that the distance C-SD and the voltage between the spinneret and the receiving metal mesh are 10 cm and 15KV respectively, and the obtained Figure 5 The shown nano nylon 6 fibers hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com