Preparation method of aqueous dispersion of aramid nano-fibers

An aqueous dispersion and nanofiber technology, applied in the field of nanomaterials, can solve the problems of low solid content of aramid nanofiber aqueous dispersion, limited application range of aramid fibers, and high requirements for construction conditions, and achieves high aspect ratio, The effect of small diameter and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

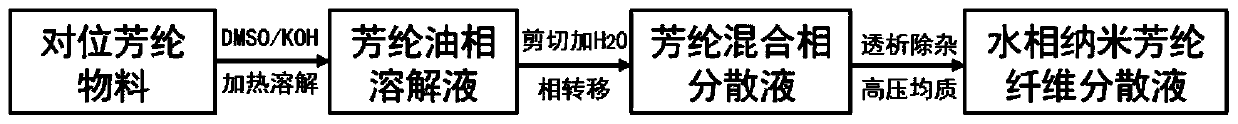

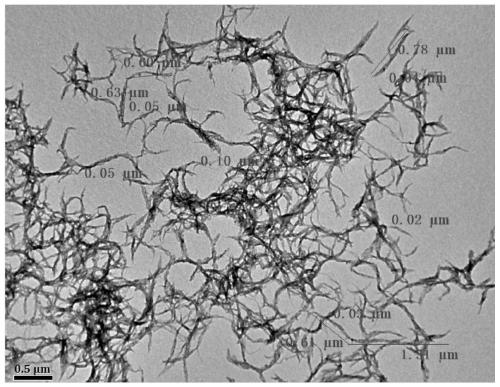

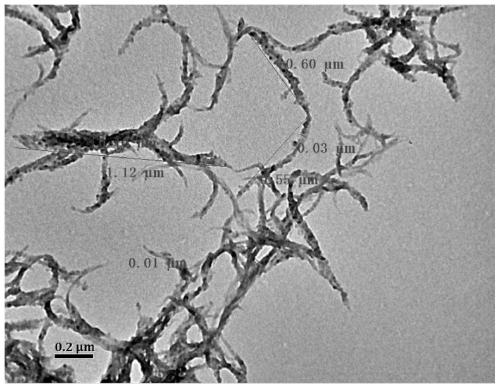

[0028] The preparation method of an aqueous dispersion of aramid fiber nanofibers provided by the invention comprises the steps of: weighing potassium hydroxide and para-aramid polymers according to a mass ratio of 0.5-2. Then the two substances are added to the dimethyl sulfoxide solution, and dissolved at 30-130°C for 2-4 days to obtain a dark red aramid fiber solution. Then under high-speed shearing conditions, add deionized water at a rate of 20-200ml / h, and then perform dialysis and high-pressure homogenization to obtain an aqueous dispersion of aramid nanofibers. After concentration, the aqueous dispersion of aramid nanofibers The body solids content can be increased to 4%. Among them, the high-speed shear rate is about 8000 rpm, the molecular weight cut-off of dialysis is 8000-14000, the high-pressure homogenization pressure is 50-150Mpa, and the homogenization is performed 2-3 times.

[0029] The present invention will be described in detail below in combination with ...

Embodiment 1

[0031] The preparation steps of a kind of aramid fiber nanofiber aqueous dispersion of the present embodiment are as follows: Weigh 4g aramid polymer and 2g potassium hydroxide respectively, then add the two substances into 170ml dimethyl sulfoxide solution, and Add 5ml of deionized water. Then dissolve at 80° C. for 2 days at a speed of 600 rpm to obtain a dark red 2% aramid fiber solution. Then, while shearing at a high speed, deionized water was added dropwise at a rate of 50 ml / h to dilute to 0.5%, and then dialysis was performed to remove dimethyl sulfoxide and other impurity ions. Finally, after three times of 150Mpa high-pressure average treatment, an aqueous dispersion of aramid fiber nanofibers with a solid content of 0.5 wt% was obtained, with a mass concentration of 5 mg / ml.

Embodiment 2

[0033] The preparation steps of a kind of aramid fiber nanofiber aqueous dispersion of the present embodiment are as follows: Weigh 4g aramid polymer and 2g potassium hydroxide respectively, then add the two substances into 170ml dimethyl sulfoxide solution, and Add 5ml of deionized water. Then dissolve at 80° C. for 2 days at a speed of 800 rpm to obtain a dark red 2% aramid fiber solution. Then, while high-speed shearing, deionized water was added dropwise at a rate of 100ml / h to dilute to 0.5%, and then dialysis was performed to remove dimethyl sulfoxide and other impurity ions. Finally, after three times of 150Mpa high-pressure average treatment, an aqueous dispersion of aramid fiber nanofibers with a solid content of 0.5 wt% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com