Prefabricated fiber dispersing device and method and application thereof

A fiber dispersion and pre-allocation technology, which is applied in the fields of chemical instruments and methods, earth square drilling, transportation and packaging, etc., can solve the problems of uneven dispersion of fibers, and achieve the effect of facilitating laying, reducing filtration loss and preventing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

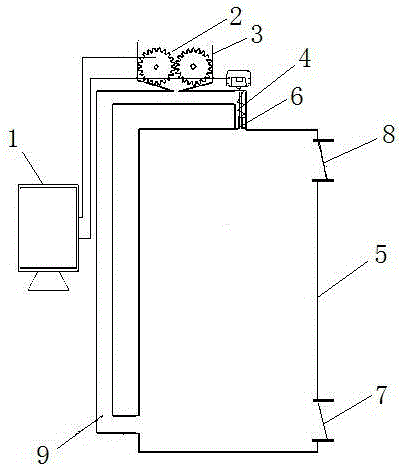

[0021] Aiming at the problem that the current fiber addition method cannot meet the requirement that the fiber is uniformly dispersed in the liquid, this example provides figure 1 A preconfigured fiber dispersing device shown includes a preconfigured tank 5, a liquid inlet 8 and a liquid outlet 7 are opened on the side wall of the preconfigured tank 5, and the liquid inlet 8 is located above the liquid outlet 7. The bottom of the dispensing tank 5 is connected with a circulation manifold 9, and the circulation manifold 9 is connected with a screw pump 4, the outlet end of the screw pump 4 communicates with the top of the pre-dispensing tank 5, and the circulation manifold 9 is equipped with a feed box 3, which feeds The bottom of the material box 3 communicates with the circulation manifold 9, and the gear disperser 2 is installed in the material box 3;

[0022] The gear disperser 2 and the screw pump 4 are all connected to a set of driving devices, and the driving devices are...

Embodiment 2

[0027] On the basis of Embodiment 1, the outlet end of the screw pump 4 is connected with a restrictor 6 .

[0028] This embodiment adopts two-stage dispersion, the fibers enter the gear disperser 2 for one-stage dispersion, the liquid mixed with fibers is sucked and pressurized by the screw pump 4, and a high-pressure zone is formed at the restrictor 6, when the mixture of high-pressure liquid and fibers flows out When restrictor 6, because the reason of pressure reduction takes place dispersion expansion, bundle fiber is dispersed into silk fiber and enters in the pre-allocation tank 5, and this is two-stage dispersion.

[0029] The liquid enters the pre-allocation tank 5 through the liquid inlet 8, the liquid in the pre-allocation tank 5 flows into the circulation manifold 9, the liquid inlet 8 and the liquid outlet 7 are closed, and the fiber is added from the opening at the top of the feed box 10, After the fibers are dispersed by the gear disperser 2, they enter the circ...

Embodiment 3

[0032] It should be noted that the gear disperser 2 is composed of two meshing gears. In order to facilitate the rapid falling of the fibers under the action of gravity, the feed box 10 is in the shape of a funnel. The driving device includes a motor and a coupling, the motor is connected to two gears or screw pumps through the coupling, and the motor is connected to the controller 1 . The added fiber length is 8mm, and in order to bend the fiber from different angles, the gear shaft length is 40cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com