Spongelike Structure and Powder, As Well As Process for Producing the Same

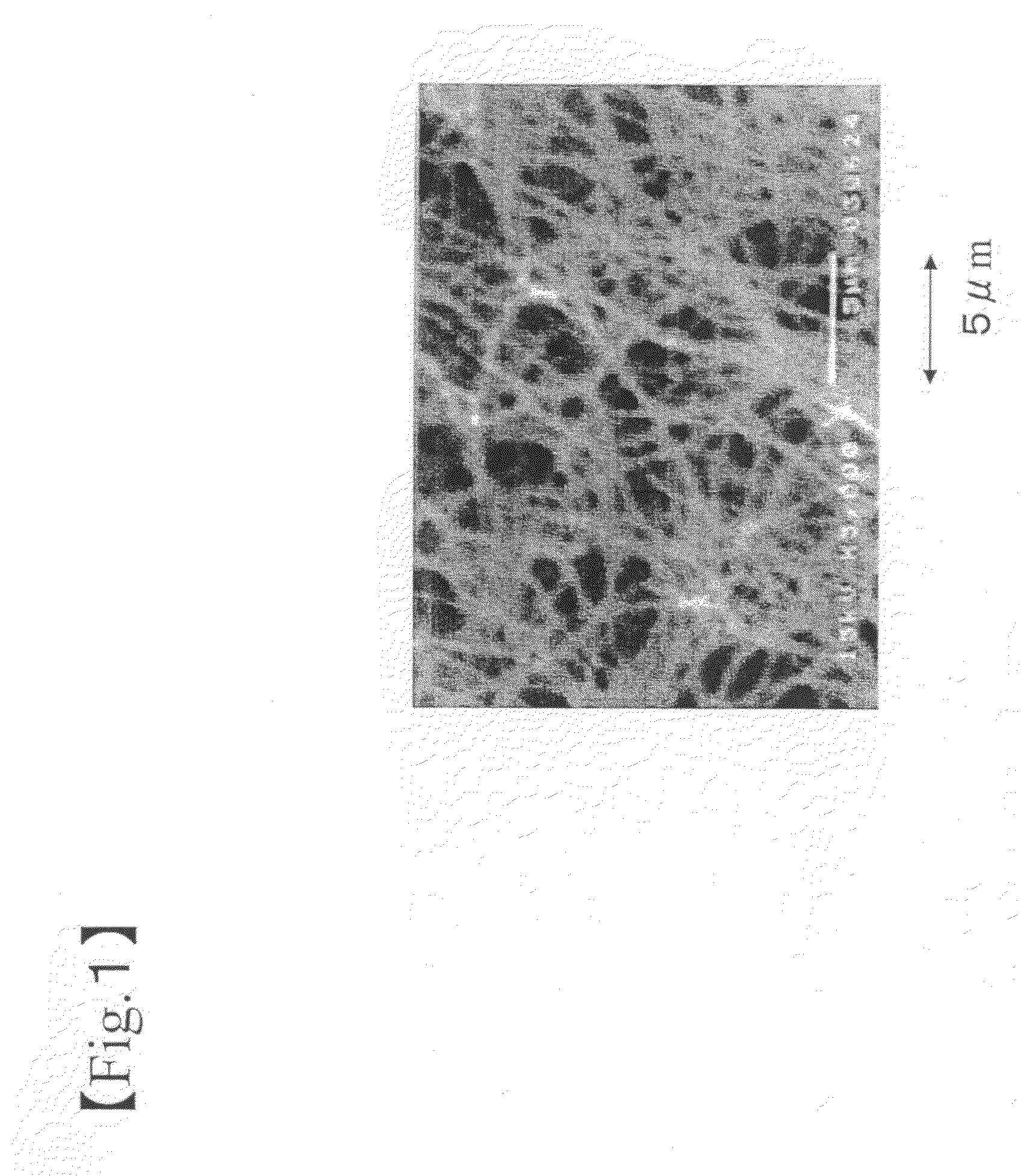

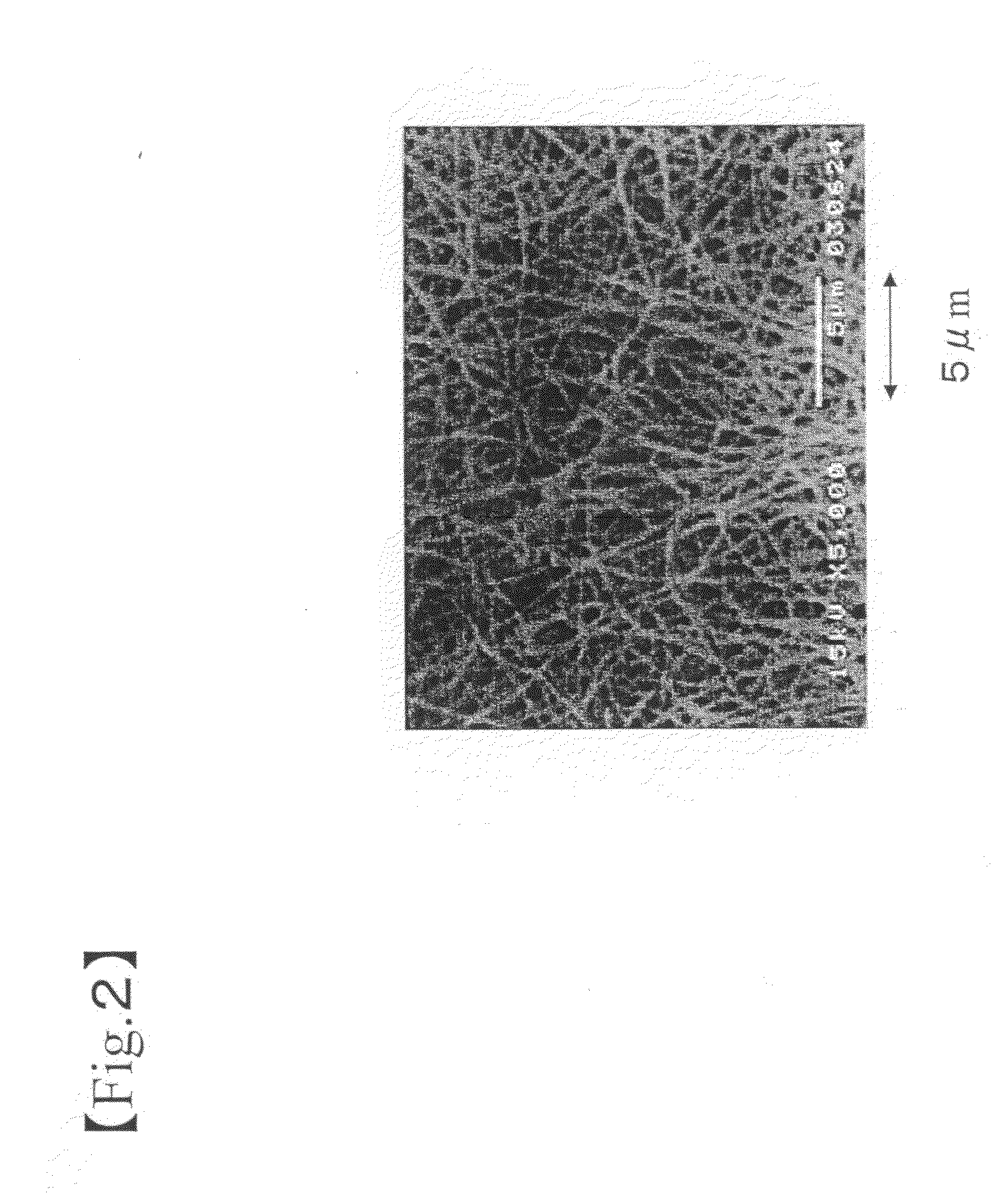

a sponge-like structure and powder technology, applied in the field of sponge-like structure or spherical powder, can solve the problems of reducing the bulkiness of the sponge-like structure, the limit of freely controlling the apparent density, and the difficulty of changing the filling density, etc., to achieve small apparent density, high porosity, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

of Dispersion

[0180]N6 (20 weight %) having a melt viscosity of 57 Pa·s (240° C., shearing rate 2432 sec−1) and a melting point of 220° C., and poly-L lactic acid (optical purity 99.5% or higher) (80 weight %) having a weight average molecular weight of 120 thousands, a melt viscosity of 30 Pa·s (240° C., shearing rate 2432 sec−1) and a melting point of 170° C. were melted and kneaded with a double-screw extruder at 220° C. to obtain a polymer alloy chip. A melt viscosity of N6 at 262° C. and a shearing rate of 121.6 sec−1 was 53 Pa·s. In addition, a melt viscosity of this poly-L lactic acid at 215° C. and a shearing rate of 1216 sec−1 was 86 Pa·s. In addition, the kneading condition thereupon was as follows.

Polymer supply: N6 and poly-L lactic acid were separately weighed, and supplied to a kneader separately.

Screw type: Same directional complete fitting type W-start thread

Screw: diameter 37 mm, effective length 1670 mm,

L / D: 45.1

[0181]A kneading part length is positioned on a discha...

production example 2

of Dispersion

[0187]According to the same manner as that of Production Example 1 of dispersion except that N6 of Production Example 1 of dispersion was changed to N6 (45 weight %) having a melt viscosity of 212 Pa·s (262° C. shearing rate 121.6 sec−1), and a melting point of 220° C., melt kneading was performed to obtain a polymer alloy chip. Then, this was melt-spun and drawing-heat-treated as in Production Example 1 of dispersion to obtain a polymer alloy fiber. The resulting alloy fiber exhibited excellent properties of 67 dtex, 36 filaments, a strength of 3.6 cN / dtex, elongation of 40%, and U %=0.7%. In addition, when a cross section of the resulting polymer alloy fiber was observed with TEM, an island in sea structure in which poly-L-lactic acid is a sea and N6 is an island was shown as in Production Example 1 of dispersion, a number mean diameter of the island N6 was 110 nm, and a polymer alloy fiber in which N6 is uniformly dispersed was obtained.

[0188]According to the same ma...

production example 3

of Dispersion

[0190]According to the same manner as that of Production Example 2 of dispersion except that a content of a N6 nano-fiber was adjusted to 0.1% by weight by changing a fiber amount after refining without changing amounts of water and a dispersant to be placed into an Oster blender (manufactured by Oster), a dispersion 3 of a N6 nano-fiber was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number mean diameter | aaaaa | aaaaa |

| number mean diameter | aaaaa | aaaaa |

| apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com