Preparation method of chitin nano fiber dispersion liquid with high carboxyl content, chitin nano fiber dispersion liquid with high carboxyl content and application

A nanofiber and chitin technology, applied in the field of chitin nanofiber preparation, can solve the problems of high cost, low yield of oxidized chitin, unsuitable pretreatment methods, etc., and achieve high production efficiency and easy operation , good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In a first aspect, in at least one embodiment, a method for preparing a high carboxyl content chitin nanofiber dispersion is provided, comprising the following steps:

[0040] Pretreating the chitin raw material to obtain chitin slurry;

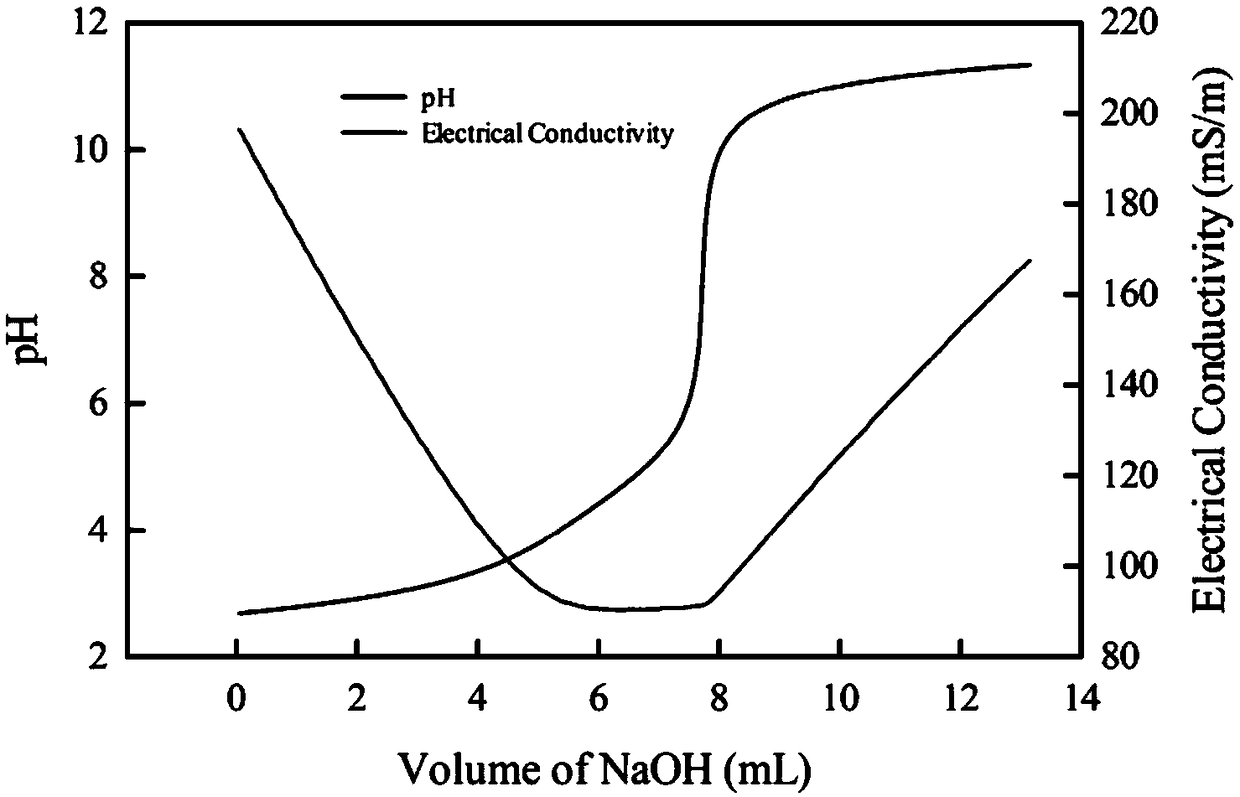

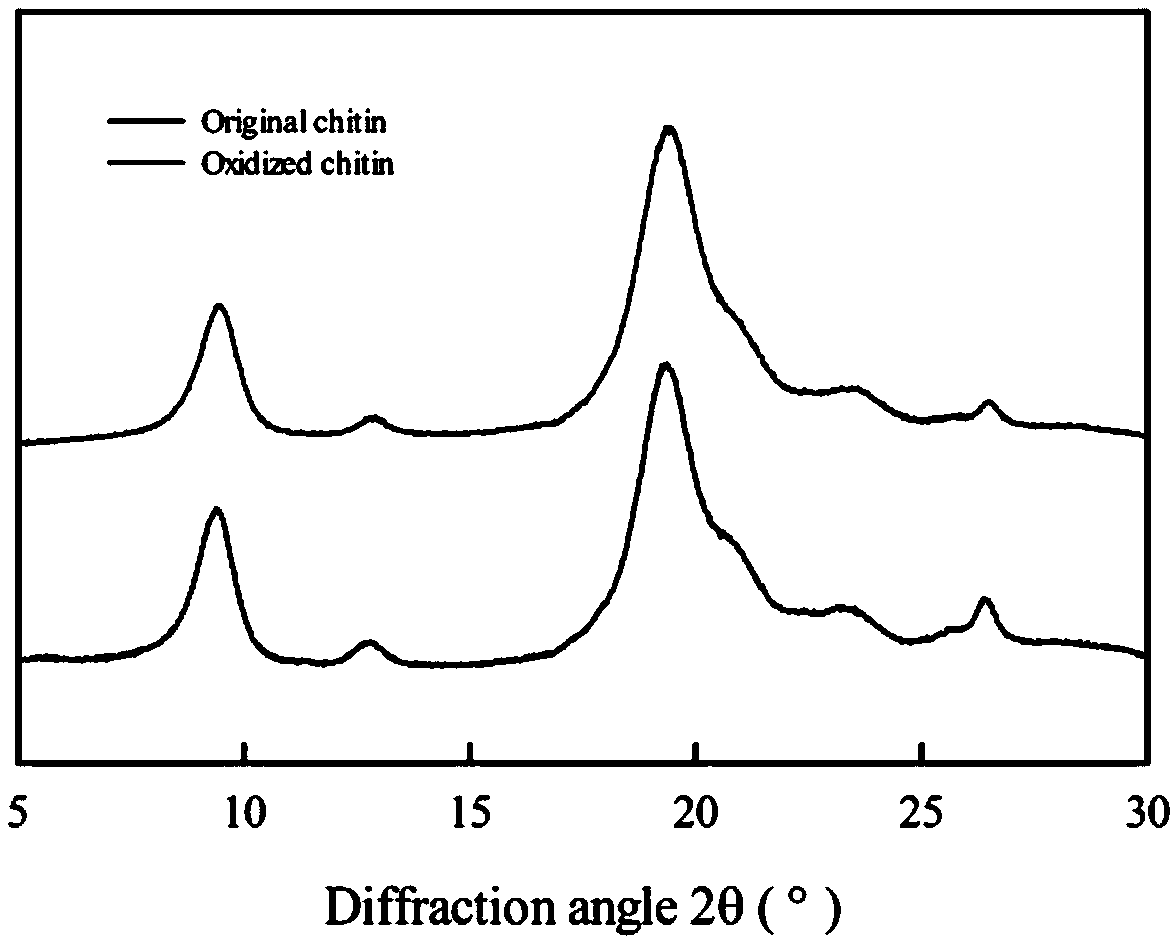

[0041] Using TEMPO-NaClO-NaClO 2 Oxidation system or TEMPO-NaBr-NaClO oxidation system oxidizes chitin slurry to obtain oxidized chitin;

[0042] Homogenize and sonicate the oxidized chitin to obtain a chitin nanofiber dispersion with high carboxyl content.

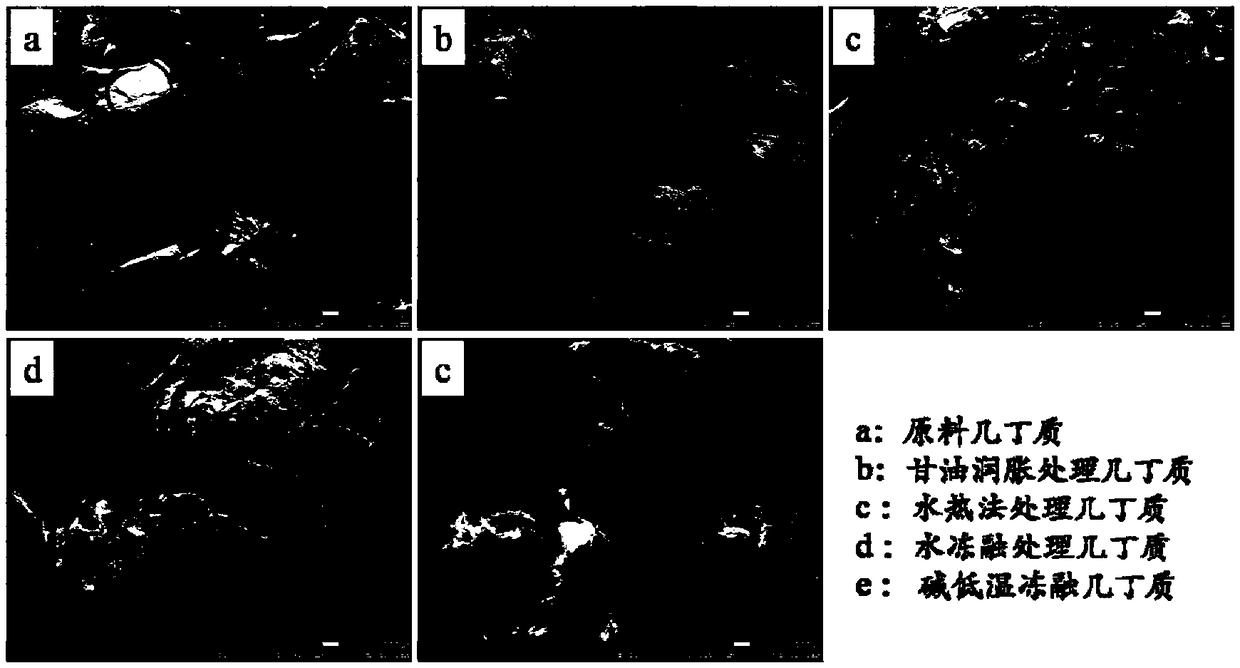

[0043] The present invention creatively utilizes pretreatment methods (such as polar solvent high-temperature or low-temperature treatment, mechanical pretreatment) in combination with TEMPO oxidation, on the one hand to reduce the amount of oxidant consumed by chitin in TEMPO oxidation, while reducing chitin On the other hand, oxidized chitin with high carboxyl content can be obtained to prepare chitin nanofibers with different properties and improve the preparation efficiency ...

Embodiment 1

[0080] A preparation method of high carboxyl content chitin nanofiber dispersion liquid, comprising the following steps:

[0081] (1) The source and purification of chitin: Crab shell (Portunus trituberculatus), produced in Nantong, China, the purification method of chitin in crab shell: 1) Cut the crab shell into 1cm 2 Size, soaked in 1 mol / L NaOH for more than 12 hours, then washed with distilled water to neutral to remove protein in crab shells; 2) soaked in 1 mol / L HCl for more than 12 hours, then washed with distilled water to neutral to remove crab shells 3) Repeat the above steps 2-3 times, wash with distilled water until neutral, and then wash with 0.5% NaClO 2 , glacial acetic acid to adjust the pH to 5.0, bleach in a 70°C water bath for 2 hours (preheat it to reach 2.5 hours), and stir intermittently (if the bleaching is not complete, wash to neutral and then perform secondary bleaching); 4) After bleaching The sample was washed with distilled water until neutral, the...

Embodiment 2

[0087] A preparation method of high carboxyl content chitin nanofiber dispersion liquid, comprising the following steps:

[0088] (1) Source and purification of chitin: squid parietal bone, squid parietal bone chitin purification method: 1) squid parietal bone is soaked in 1mol / L NaOH for more than 12h, and then washed with distilled water until neutral to remove squid parietal bone Protein; 2) Soak in 1mol / L HCl for more than 12 hours, then wash with distilled water until neutral to remove calcium salts and other components in the squid parietal bone; 3) Repeat the above steps 2-3 times, wash with distilled water until neutral, and then with 0.5% NaClO 2 , glacial acetic acid to adjust the pH to 5.0, bleach in a 70°C water bath for 2 hours (preheat it first to reach 2.5 hours), and stir intermittently (if the bleaching is not complete, wash to neutral and then perform secondary bleaching); 4) After bleaching The sample was washed with distilled water until neutral, then pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com