High-gloss high-opacity coefficient paint for papers, preparation method and application thereof

A transparency and high-gloss technology, applied in paper coating, paper, papermaking, etc., to achieve excellent gloss and save consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

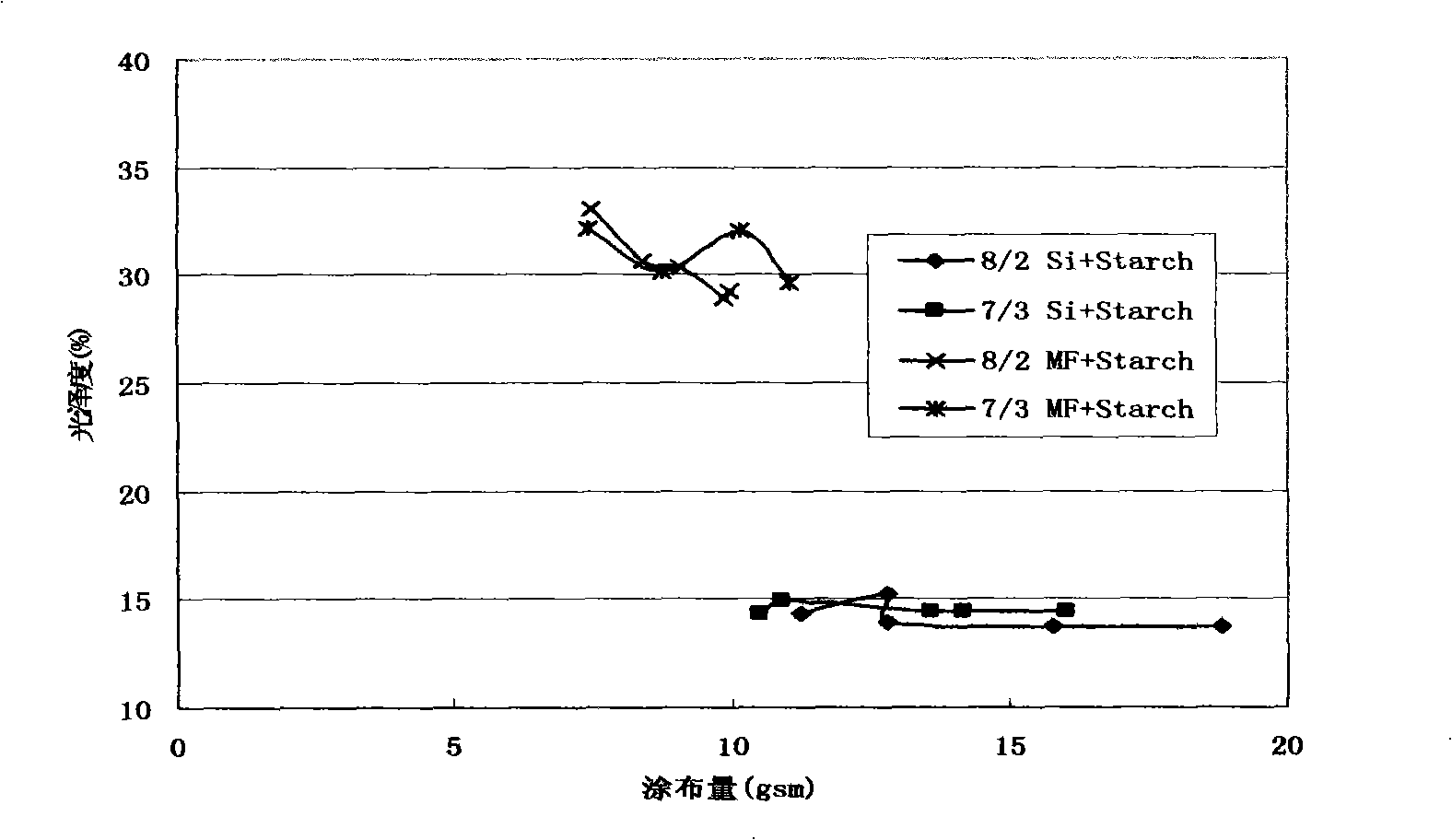

[0030] Disperse the microfibers into a dispersion suspension with a mass concentration of 10% to obtain a microfiber slurry. The microfiber slurry is mixed with a polymer aqueous solution (starch aqueous solution) with a mass concentration of 30%. In the coating for transparent paper, the dry mass ratio of the microfiber slurry to the polymer aqueous solution is 1.5:1.

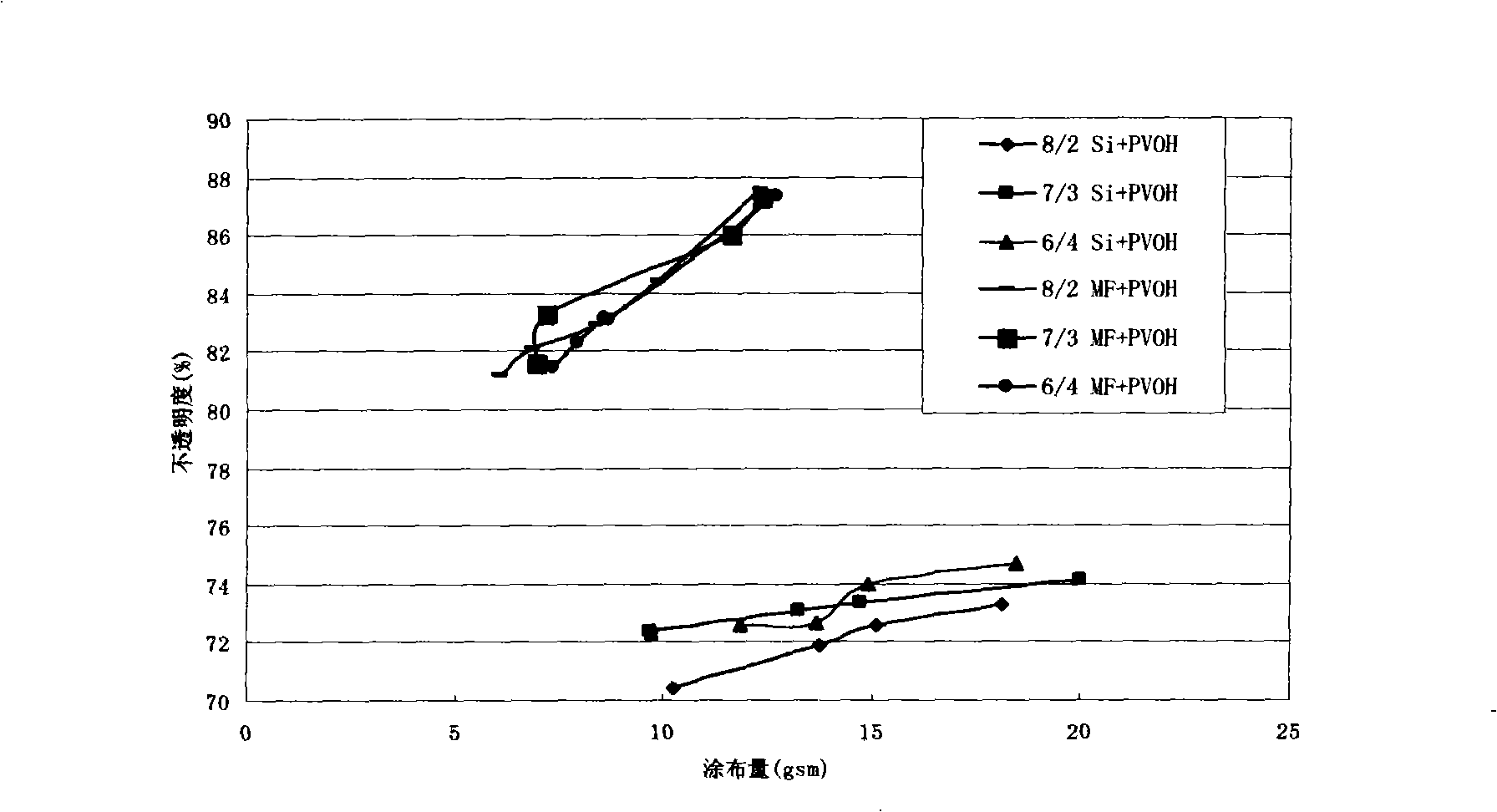

[0031] The solid content of the high-gloss high-opacity paper coating is 15%, and the viscosity is 1200cp; when the coating amount is 10gsm, the paper gloss is increased by 18 degrees, the paper opacity is increased by 12 degrees, and the paper brightness is increased by 3 degrees.

[0032] When the above paper coating is applied to a paper base with a gloss of 14%, an opacity of 69%, and a brightness of 85%, the resulting paper with a coating weight of 10 gsm has a gloss of 32% and an opacity of 81. %, the brightness is 88 degrees.

Embodiment 2

[0034] Disperse the microfibers into a dispersion suspension with a mass concentration of 20% to obtain a microfiber slurry. The microfiber slurry is mixed with a polymer aqueous solution (latex aqueous solution) with a mass concentration of 50%, stirred for 30 minutes, and the rotating speed is 200 rpm , After being uniform, the paper coating with high gloss and high opacity is obtained, and the dry mass ratio of the microfiber slurry to the polymer aqueous solution is 4:1.

[0035] The solid content of the above-mentioned high-gloss high-opacity paper coating is 30%, and the viscosity is 700cp; when the coating amount is 8gsm, the glossiness of the paper is increased by 26%, the opacity of the paper is increased by 18%, and the brightness of the paper is increased by 3%. .

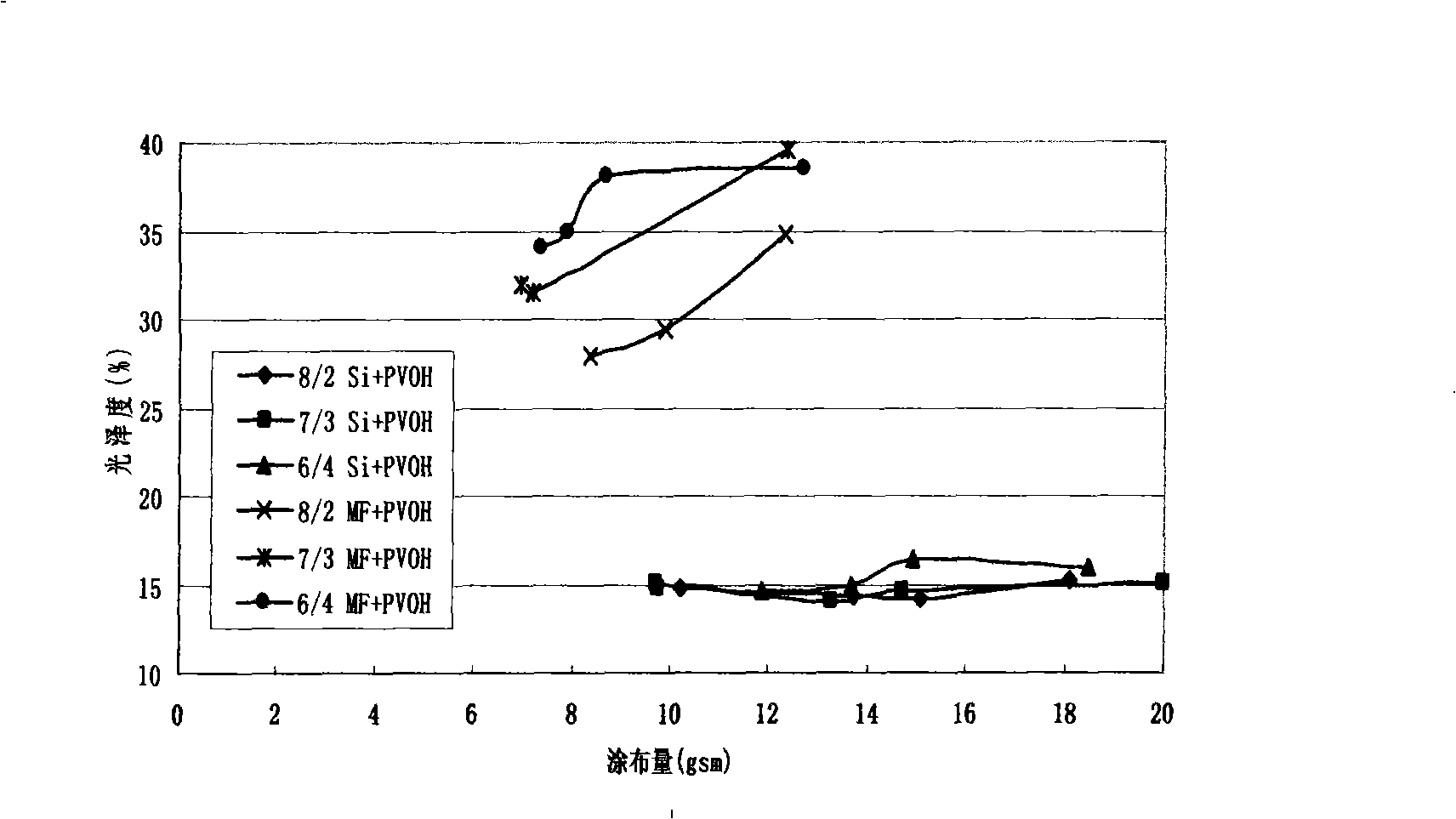

[0036] When the above paper coating is applied to a paper base having a gloss of 14%, an opacity of 69%, and a brightness of 85%, the resulting paper has a gloss of 40% and an opacity of 87% at a coating...

Embodiment 3

[0038]Disperse the microfibers into a dispersion suspension with a mass concentration of 30% to obtain a microfiber slurry, mix the microfiber slurry with a polymer aqueous solution (aqueous solution of polyvinyl alcohol) with a mass concentration of 10%, and stir evenly to obtain high gloss In the coating for high-opacity paper, the dry mass ratio of the microfiber slurry to the polymer aqueous solution is 3:1.

[0039] The above-mentioned coating for high-gloss and high-opacity paper has a solid content of 20% and a viscosity of 900cp; when the coating amount is 10gsm, the glossiness of the paper is increased by 23 degrees, the opacity of the paper is increased by 15 degrees, and the brightness of the paper is increased by 3 degrees.

[0040] When the above paper coating is applied to a paper base with a gloss of 14%, an opacity of 69%, and a brightness of 85%, the resulting paper has a gloss of 37% and an opacity of 84 at a coating weight of 10 gsm. %, the brightness is 88 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com