Hybrid fire retardant and preparing method thereof

A flame retardant and hybridization technology, which is applied in the field of hybrid flame retardants and their preparation, can solve the problems of low flame retardant efficiency, affecting the application of high polymers, and the impact of high polymer mechanical properties, and achieve high flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

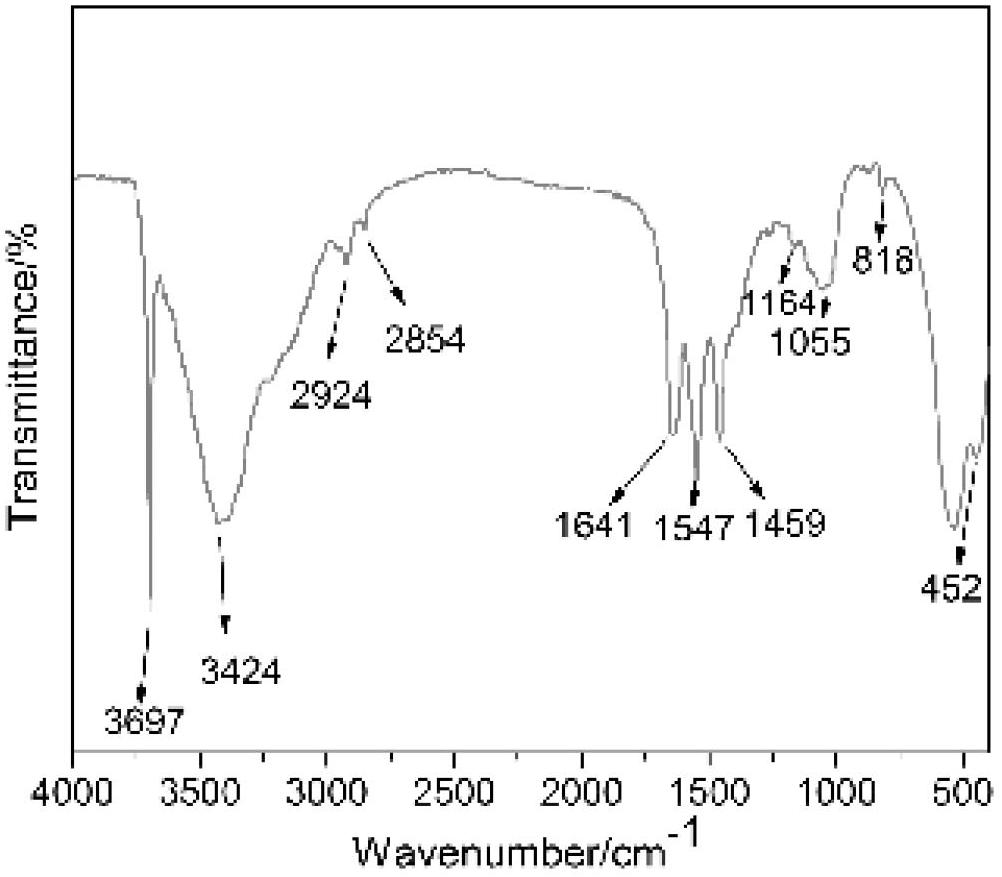

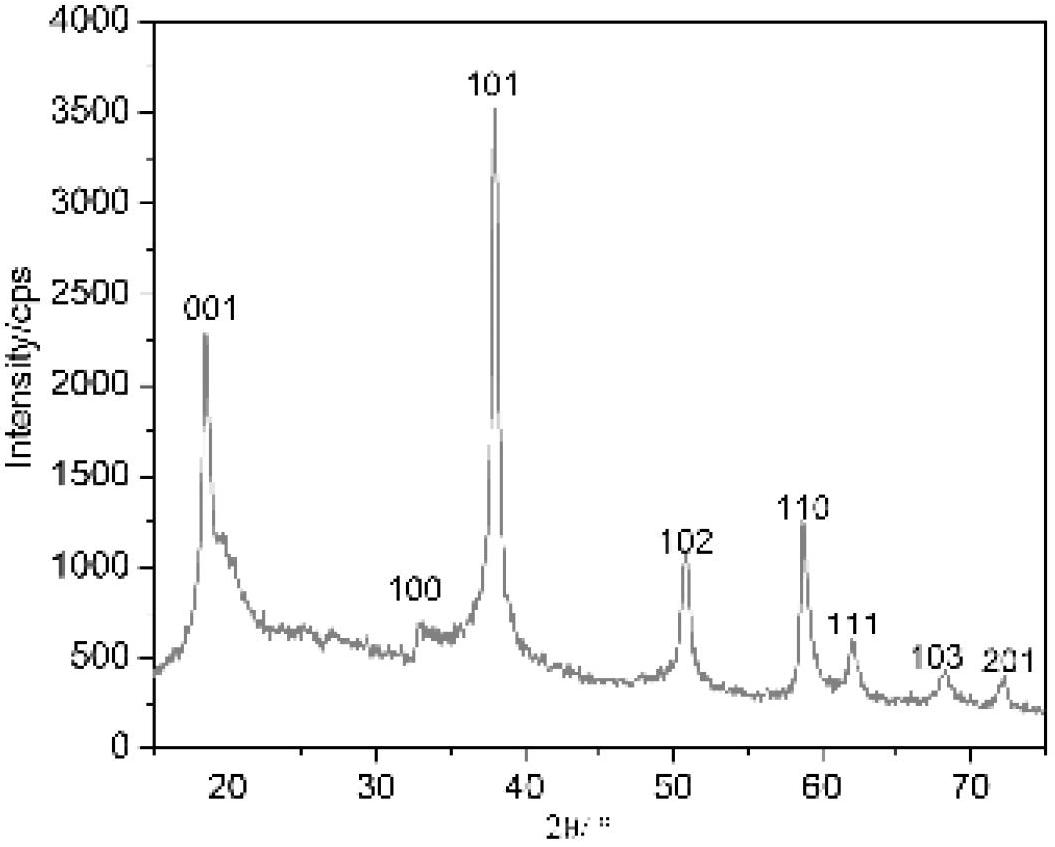

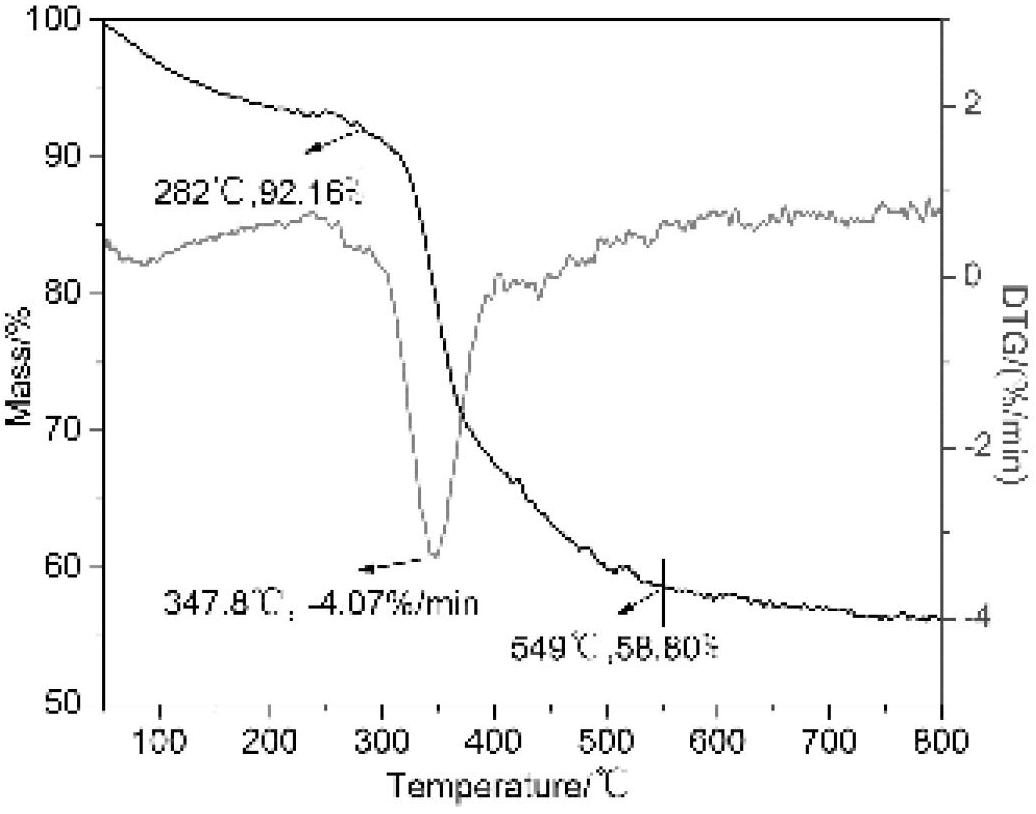

Method used

Image

Examples

Embodiment 1

[0027] (1) Measure 0.37ml of 37% formaldehyde solution (0.005mol), dilute it with 20ml of water and adjust the pH value to 8-9, add 0.63g (0.005mol) of melamine, stir well at 70°C until the liquid surface is clear , to obtain melamine formaldehyde prepolymer.

[0028] (2) Weigh 20.3g bittern, dissolve it in deionized water, add 1-2ml H 2 o 2 , after fully stirring, let it stand still, filter to obtain the filtrate after 4-5h, and adjust the pH to 2.5 after constant volume in a 200ml volumetric flask.

[0029] (3) Put the above-mentioned 200ml of bittern in a three-necked flask with condensing reflux and stirring, fully stir at 70°C and 300r / min, and add the melamine formaldehyde prepolymer obtained in step (1) dropwise into bittern In the brine, when the liquid level changes from transparent to light blue or white after the addition, quickly lower the temperature to 25°C and increase the speed to 500r / min at the same time. After the temperature stabilizes for 10 minutes, sta...

Embodiment 2

[0031] (1) Measure 0.92ml of 37% formaldehyde solution (0.0125mol), dilute it with 20ml of water and adjust the pH value to 8-9, add 0.63g (0.005mol) of melamine, stir well at 70°C until the liquid surface is clear , to obtain melamine formaldehyde prepolymer.

[0032] (2) Weigh 20.3g bittern, dissolve it in deionized water, add 1-2ml H 2 o 2 , after fully stirring, let it stand still, filter to obtain the filtrate after 4-5h, and adjust the pH to 2.5 after constant volume in a 200ml volumetric flask.

[0033] (3) Put the above-mentioned 200ml of bittern in a three-necked flask with condensing reflux and stirring, fully stir at 70°C and 300r / min, and add the melamine formaldehyde prepolymer obtained in step (1) dropwise into bittern In the brine, when the liquid level changes from transparent to light blue or white after the addition, quickly lower the temperature to 25°C and increase the speed to 500r / min at the same time. After the temperature stabilizes for 10 minutes, st...

Embodiment 3

[0035] (1) Measure 2.21ml of 37% formaldehyde solution (0.03mol), dilute it with 40ml of water and adjust the pH value to 8-9, add 2.52g (0.005mol) of melamine, stir well at 70°C until the liquid surface is clear , to obtain melamine formaldehyde prepolymer.

[0036] (2) Weigh 20.3g bittern, dissolve it in deionized water, add 1-2ml H 2 o 2 , after fully stirring, let it stand still, filter to obtain the filtrate after 4-5h, and adjust the pH to 2.5 after constant volume in a 200ml volumetric flask.

[0037] (3) Put the above-mentioned 200ml bittern solution in a three-neck flask with condensing reflux and stirring, fully stir at 70°C and 300r / min, measure 20ml of the melamine formaldehyde prepolymer obtained in step (1) dropwise Add it into the bittern solution, and when the liquid level changes from transparent to light blue or white after the addition, quickly lower the temperature to 25°C and increase the speed to 500r / min, and start adding ammonia water dropwise after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com