Adhesive and sealant systems

A technology of sealants and adhesives, applied in the direction of non-polymer adhesive additives, adhesive additives, adhesives, etc., which can solve problems such as use restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0152] I. Preparation of Fumed Silica of the Invention

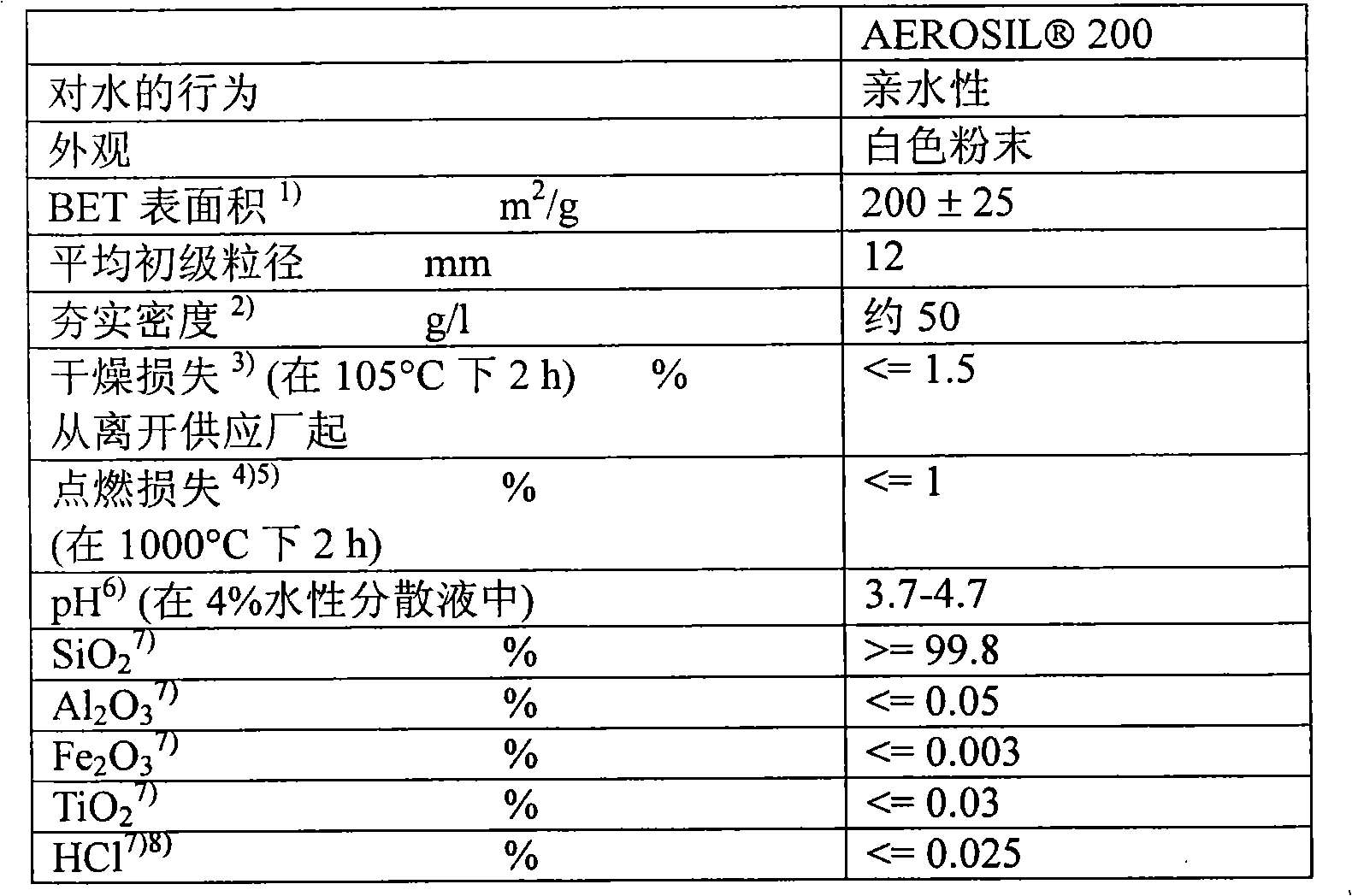

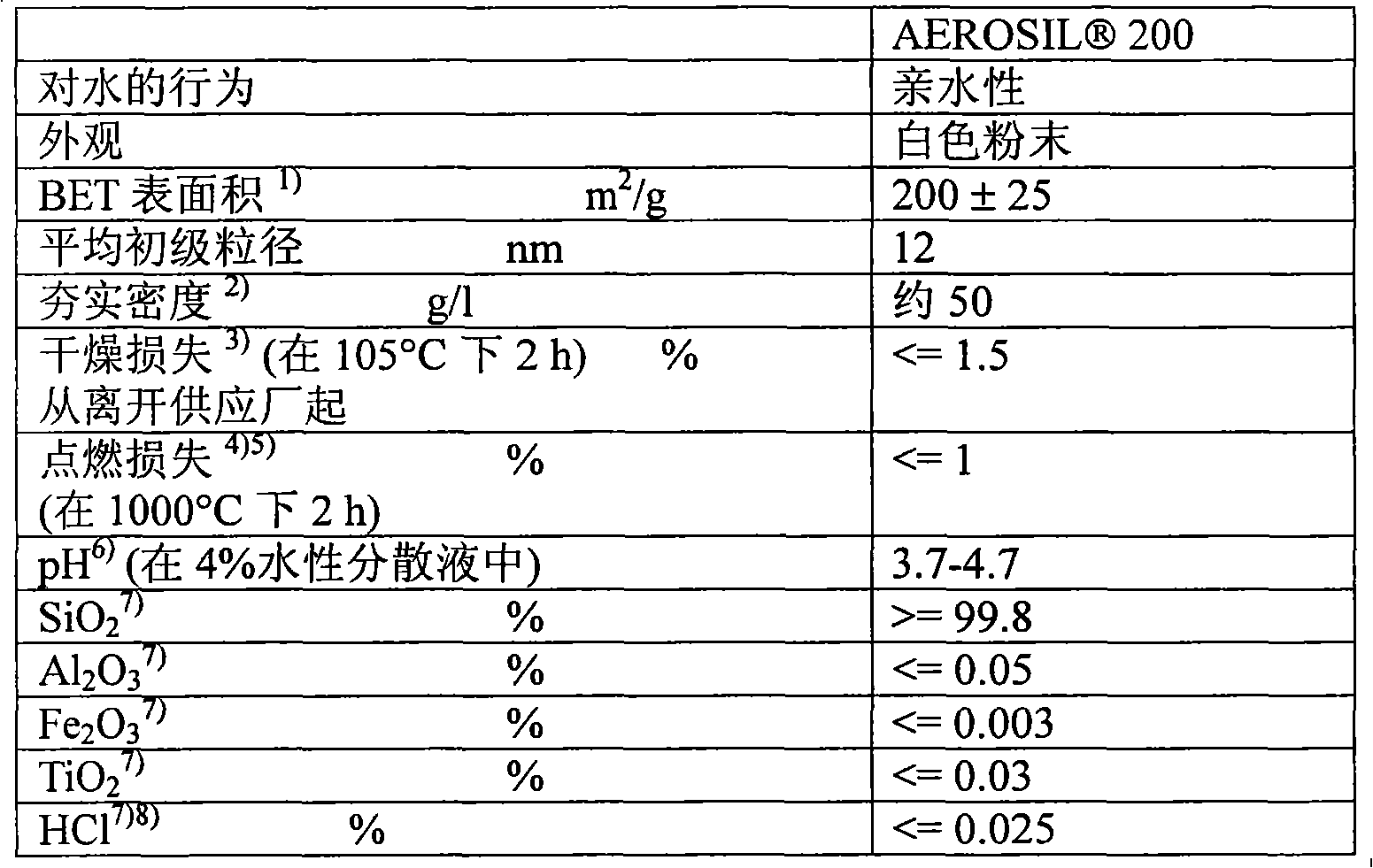

[0153] By using a metrological balance will be commercially available 200 (bag product) was metered into the grinder used and ground to prepare the examples of the present invention. 200 has the physical and chemical properties listed in Table 1.

[0154] Table 1

[0155] Fumed silica used

[0156]

[0157] 1) According to DIN ISO 9277

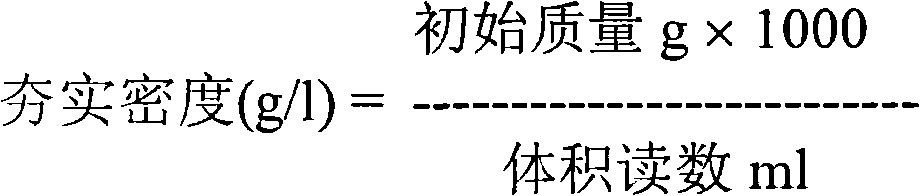

[0158] 2) According to DIN EN ISO 787-11, JIS K 5101 / 20 (not sieved)

[0159] 3) According to DIN EN ISO 787-2, ASTM D 280, JIS K 5101 / 23

[0160] 4) According to DIN EN 3262-20, ASTM D 1208, JIS K 5101 / 24

[0161] 5) Based on material dried at 105°C for 2 hours

[0162] 6) According to DIN EN ISO 787-9, ASTM D 1208, JIS K 5101 / 26

[0163] 7) Based on material calcined at 1000°C for 2 hours

[0164] 8) HCl content in ignition loss components

[0165] Experiments were performed using a pin-disc mill (Alpine 160Z, rotor diameter 160 mm) or an air jet mill (grinding chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com