High-glowing filament anti-soaking separate-out-free halogen-free inflaming retarding polypropylene materials and preparation method thereof

A technology of flame-retardant polypropylene and high glow wire, which is applied in the field of halogen-free flame-retardant polypropylene materials, can solve the problems of appearance and flame-retardant performance degradation, affecting material performance, and large smoke generation, so as to facilitate large-scale promotion The use and production process are simple, and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention is a basic preparation method of a high-glow wire immersion-resistant precipitation-free halogen-free flame-retardant polypropylene material. The steps of the method are as follows:

[0032] (1) Weigh the organic or inorganic hypophosphite wrapped in silane, halogen-free organic phosphate or its derivatives wrapped in MF, and melamine cyanurate according to the ratio of the components of the compound halogen-free flame retardant above, and add Stir fully in a high-speed mixer to make it evenly mixed to obtain a compound halogen-free intumescent flame retardant;

[0033] (2) Weigh PP resin, compound halogen-free flame retardant, flame retardant synergist, inorganic filler, antioxidant, lubricant according to the above ratio, add it to a high-speed mixer and mix for 3~5 minutes, and mix at a high speed The speed of the machine is 500~2000 r / min;

[0034] (3) Put the mixed material into the parallel twin-screw extruder to extrude and granulate.

[0...

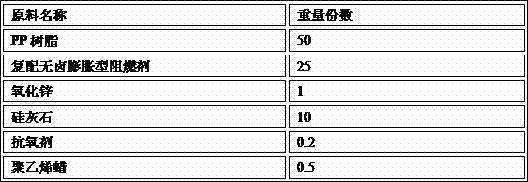

Embodiment 1

[0038] In the present embodiment, the composite halogen-free flame retardant is 30 parts of aluminum hypophosphite wrapped by silane, 35 parts of spirocyclic phosphate ester wrapped by MF, and 15 parts of melamine cyanurate in parts by weight of each component. Fully stir in a high-speed mixer to make it evenly mixed to obtain a compound halogen-free intumescent flame retardant. The preparation method of the compound halogen-free flame retardant in Examples 1-5 is the same. The antioxidant is a mixture of phosphite antioxidant 168 and hindered phenolic antioxidant 1010, and the antioxidants in Examples 1 to 5 are the same. The composition of raw materials for preparing halogen-free flame retardant materials is as follows in Table 1:

[0039]

[0040] Table 1

[0041] Its preparation method is,

[0042] (1) Weigh various raw materials according to the weight ratio in the table;

[0043] (2) Put the raw materials into the high-speed mixer and mix for 3-5 minutes, the spee...

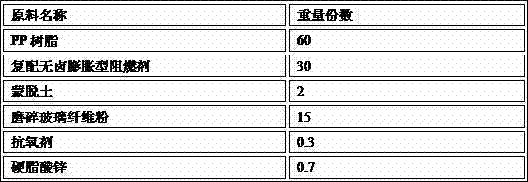

Embodiment 2

[0047] In this example, the compound halogen-free flame retardant is 50 parts by weight of each component, 50 parts of zinc phenyl hypophosphite wrapped in silane, 35 parts of bisphenol A-bis(diphenyl phosphate) wrapped in MF, melamine cyanide The uric acid ester is 20 parts, which is added into a high-speed blender and fully stirred to make it evenly mixed to obtain a compound halogen-free intumescent flame retardant. The composition of raw materials for preparing halogen-free flame retardant materials is as follows in Table 2:

[0048]

[0049] Table 2

[0050] Its preparation method is identical with the preparation method of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com