A mud-water pulse mixing device

A pulse mixing and muddy water technology, applied in mixers, transportation and packaging, dissolving and other directions, can solve the problems of easy failure, affecting the denitrification effect, small mixing maintenance, etc., to achieve the effect of high-efficiency mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

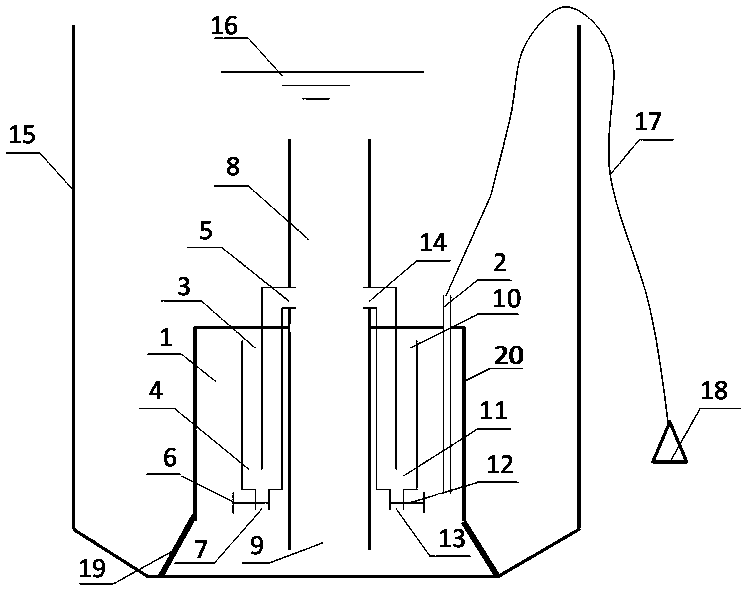

[0023] figure 1 It is a structural schematic diagram of a slurry pulse mixing device of the present invention. Such as figure 1 As shown, a mud-water pulse mixing device includes a gas-collecting hood 20 and a gas-liquid riser 8, and the gas-collecting hood 20 is connected with the gas-liquid riser 8, so that the outer wall of the gas-liquid riser 8 and the inner wall of the gas-liquid riser 20 A gas collection chamber 1 is formed between them, and the gas collection chamber 1 is provided with an air supply pipe 2, a left U-shaped air outlet pipe 4 and a right U-shaped air outlet pipe 11, the air supply pipe 2 is connected to the air pump 18 through the air pipe 17, and the lower end of the gas-liquid lift pipe 8 passes through The gas-liquid riser inlet 9 communicates with the bottom of the gas collection chamber 1; the left U-shaped air outlet pipe 4 is provided with a left air inlet 3 and a left air discharge port 5, and the gas collection chamber 1 passes through the left...

Embodiment 2

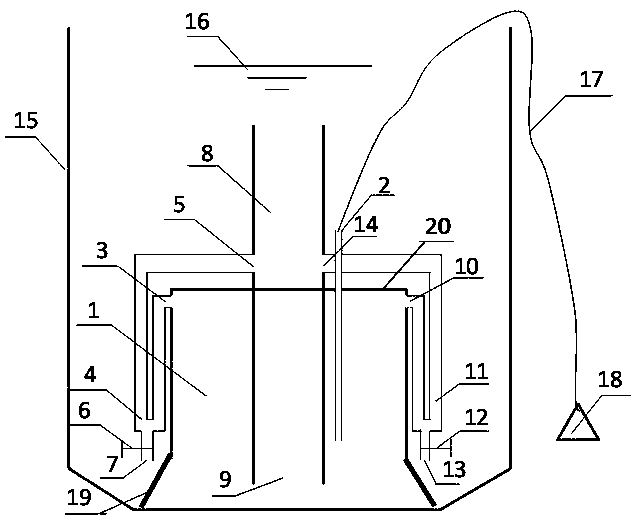

[0030] This embodiment is the second embodiment of the present invention. The difference from Embodiment 1 is that the left U-shaped air outlet pipe 4 and the right U-shaped air outlet pipe 11 are arranged outside the air collecting chamber 1 . All the other parts are identical with embodiment 1 with connection mode, as figure 2 shown. This design simplifies the internal structure of the gas collection chamber 1, thereby reducing blockage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com