Low-odor high-dispersion foaming master batch, and preparation method and application thereof

A foaming masterbatch and high dispersion technology, applied in the field of polymer materials, can solve the problems affecting the odor, uneven dispersion and degradation of modified plastic products, so as to avoid the influence of product appearance, fine cell diameter and low odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

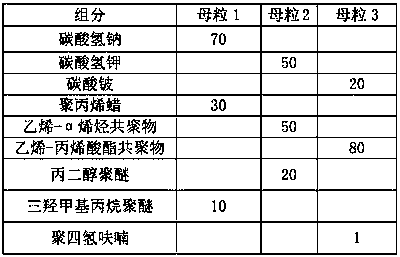

[0033] A kind of preparation method of low smell, highly dispersed foaming masterbatch, comprises the following steps:

[0034] Step 1: Add 30-80 parts of carrier resin, 1-20 parts of polyether polyol, 1-10 parts of odor improver, 0.5-5 parts of dispersant, 1-10 parts of interface modifier, and 0.5-2.0 parts of additive Mix in a high-speed mixer for 1-3 minutes to obtain the mixed material;

[0035] Step 2: Feed the mixed material obtained in Step 1 into the extruder through the hopper of the twin-screw extruder, and then feed 20-70 parts of the foaming agent into the extruder through the second-stage side feeding port, after plasticizing and extruding , Granulation to obtain low-odor, high-dispersion foaming masterbatch.

[0036] The foaming agent is one of carbonates, bicarbonates, and alkali metal hydroxides, and the particle size is less than or equal to 5 μm, preferably a particle size of 2mm bicarbonate foaming agent, such as sodium bicarbonate, carbonic acid Potassium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com