Cardanol grafted high-density polyethylene synthesized by reactive extrusion and application thereof in bamboo-plastic composite material

A technology of high-density polyethylene and composite materials, applied in the field of reactive extrusion synthesis of cardanol grafted high-density polyethylene, to achieve the effects of preventing thermal degradation, increasing grafting rate, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

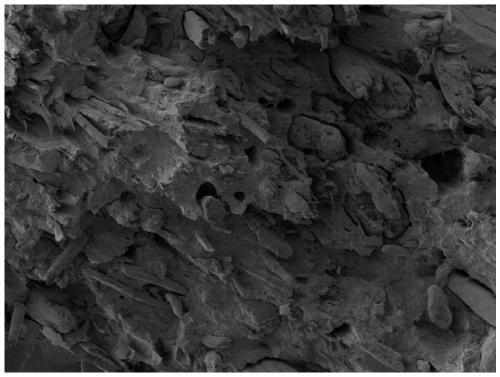

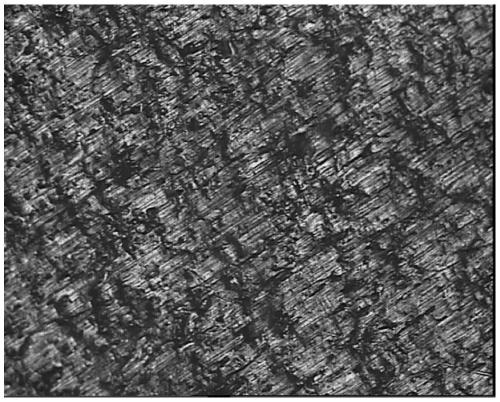

Image

Examples

Embodiment 1

[0019] step one

[0020] After 1g of lauroyl peroxide (LPO) and 1g of dibenzoyl peroxide (BPO) were dissolved in 70g of cardanol, they were added to 1000g of high-density polyethylene (HDPE) resin, stirred at a high speed and mixed evenly, and then extruded with a twin-screw. The extruder (the temperature of the solid conveying section, the melting section, the reaction mixing section, and the melt conveying section of the extruder are respectively 150°C, 160°C, 170°C, and 160°C) is extruded, water-cooled, and granulated to obtain a reactive extruded product. The product cardanol grafted high-density polyethylene (grafting rate 6.82%);

[0021] step two

[0022] After 1000g cardanol grafted high-density polyethylene and 300g bamboo powder are mixed evenly at a high speed, utilize twin-screw extruder (the temperature of extruder solid delivery section, melting section, reaction mixing section and melt delivery section is respectively 150°C, 160°C, 170°C, 160°C) to obtain bamb...

Embodiment 2

[0025] step one

[0026] After 0.1g of lauroyl peroxide (LPO) and 2g of dibenzoyl peroxide (BPO) were dissolved in 150g of cardanol, they were added to 1000g of high-density polyethylene (HDPE) resin. The extruder (the temperature of the extruder solid delivery section, melting section, reaction mixing section, and melt delivery section are 150°C, 160°C, 170°C, and 160°C respectively) is extruded, water-cooled, and granulated to obtain the reaction Extrusion product cardanol grafted high-density polyethylene (grafting rate 4.73%);

[0027] step two

[0028] 1000g of cardanol-grafted high-density polyethylene and 700g of bamboo powder were mixed evenly at high speed, and then hot-pressed at a temperature of 160°C by a hot press to obtain a bamboo-plastic composite material.

Embodiment 3

[0030] step one

[0031] After dissolving 2g of lauroyl peroxide (LPO) and 0.1g of dibenzoyl peroxide (BPO) in 70g of cardanol, add it to 1000g of high-density polyethylene (HDPE) resin, stir and mix evenly at a high speed, and then use a twin-screw The extruder (the temperature of the extruder solid delivery section, melting section, reaction mixing section, and melt delivery section are 140°C, 140°C, 150°C, and 140°C respectively) is extruded, water-cooled, and granulated to obtain the reaction Extrusion product cardanol grafted high-density polyethylene (grafting rate 4.27%);

[0032] step two

[0033] After mixing 1000g of cardanol-grafted high-density polyethylene with 500g of bamboo powder at a high speed, they are extruded using an injection molding machine (the heating temperature is 150°C, 150°C, 160°C, and 170°C from the feed inlet) to obtain bamboo plastic. composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com