Glass fiber grid adhesive tape and preparation method thereof

A technology of glass fiber and grid, which is applied in the field of glass fiber grid tape and its preparation, which can solve the problems of insufficient adhesive performance and easy falling off, and achieve the effect of strong viscosity, high bidirectional tensile strength and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

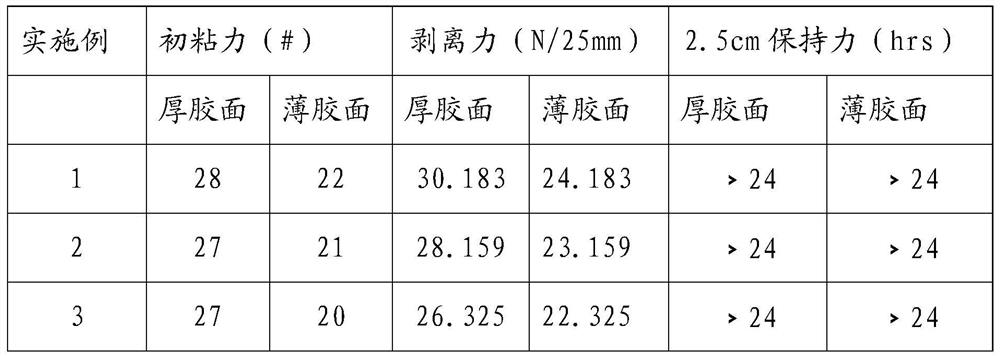

Examples

preparation example Construction

[0022] Further, the preparation method of above-mentioned fiberglass mesh adhesive tape, comprises the following steps:

[0023] Step 1: Put 0.5-1.0 parts of acrylic acid, 0.3-0.5 parts of hydroxyethyl acrylate, 29-32 parts of isooctyl acrylate, 9-11 parts of butyl acrylate and 7-10 parts of vinyl acetate into the emulsification tank, turn on the stirring and mixing for 10 Minutes to obtain mixed products;

[0024] Step 2: Put half of the total amount of the mixed product into the reaction furnace, put 40-44 parts of ethyl acetate in the reaction furnace, turn on the stirring, feed nitrogen, the speed of the reaction furnace is 25 revolutions per minute, and the temperature is raised to 74-76°C;

[0025] Step 3: Mix 0.2-0.3 parts of lauroyl peroxide and 7-9 parts of ethyl acetate, and titrate in the reaction furnace. Boiling phenomenon will appear after titration for about 20 minutes, and the temperature will rise to 85-86 ° C. Stop titration, and the temperature Drop to 63-...

Embodiment 1

[0041] Step 1: Put 0.7 parts of acrylic acid, 0.4 parts of hydroxyethyl acrylate, 30 parts of isooctyl acrylate, 10 parts of butyl acrylate and 8 parts of vinyl acetate into the emulsification tank, turn on the stirring and mixing for 10 minutes to obtain a mixed product;

[0042] Step 2: Put half of the total amount of the mixed product into the reaction furnace, put 42 parts of ethyl acetate in the reaction furnace, turn on the stirring, feed nitrogen, the speed of the reaction furnace is 25 revolutions per minute, and the temperature is raised to 75°C ;

[0043] Step 3: Mix 0.25 parts of lauroyl peroxide and 8 parts of ethyl acetate, and titrate in the reaction furnace, the temperature rises to 85°C, stop the titration, the temperature drops to 65°C, continue the titration, open the emulsification tank at the same time, in the reaction Put the other half of the mixed product in the furnace, continue to titrate to 150 minutes, cool down and unload the glue after 4 hours of h...

Embodiment 2

[0051] Step 1: Put 0.5 parts of acrylic acid, 0.3 parts of hydroxyethyl acrylate, 29 parts of isooctyl acrylate, 9 parts of butyl acrylate and 7 parts of vinyl acetate into the emulsification tank, turn on the stirring and mixing for 10 minutes to obtain a mixed product;

[0052] Step 2: Put half of the total amount of the mixed product into the reaction furnace, put 40-44 parts of ethyl acetate in the reaction furnace, turn on the stirring, feed nitrogen, the speed of the reaction furnace is 25 revolutions per minute, and the temperature is raised to 74°C;

[0053] Step 3: Mix 0.2 parts of lauroyl peroxide and 7 parts of ethyl acetate, and titrate in the reaction furnace. Boiling will appear after about 20 minutes of titration, and the temperature will rise to 85°C. Stop titration, and the temperature will drop to 63°C. Continue Titrate, open the emulsification tank at the same time, put the other half of the mixed product in the reaction furnace, continue to titrate to 150 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com