Ramming paste adhesive for aluminum electrolytic cells and preparation method thereof

An aluminum electrolytic cell and tamping paste technology, applied in the field of chemical electrolysis, can solve the problems of poor acid and alkali resistance, unable to function stably for a long time, and weak pressure resistance, and achieve good bonding strength and pressure resistance. and the effect of acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

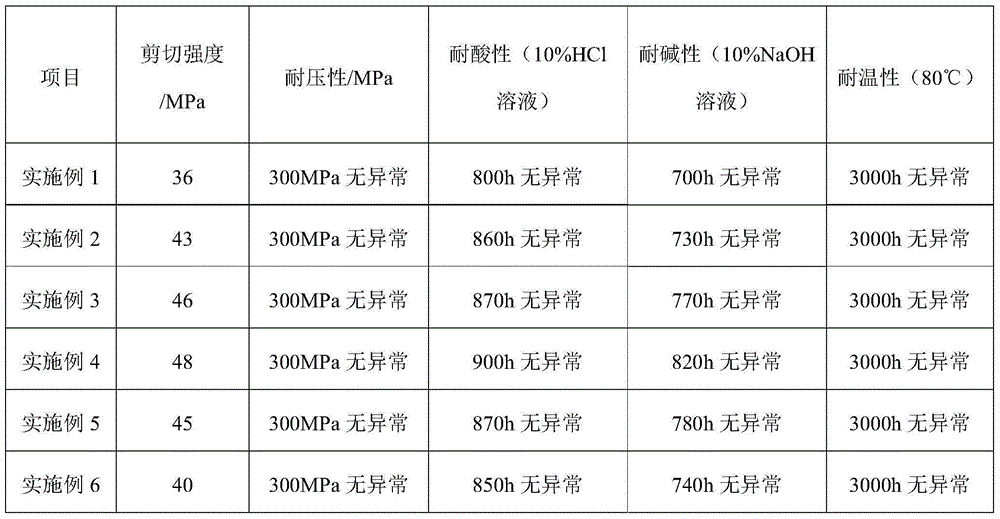

Examples

Embodiment 1

[0018] A tamp paste binder for an aluminum electrolytic cell, comprising the following components by weight components: 10 parts of brominated epoxy resin, 1 part of antimony trioxide, 1 part of carnauba wax, 2 parts of glycidyl methacrylate 1 part, 1 part of silane coupling agent, 1 part of lauroyl peroxide, 2 parts of stearic acid, 1 part of barium stearate, 5 parts of phenolated polybutadiene.

[0019] The preparation method of the above-mentioned aluminum electrolytic cell tamping paste binder comprises the following steps:

[0020] Step 1, adding brominated epoxy resin, antimony trioxide, carnauba wax, glycidyl methacrylate, stearic acid, barium stearate and phenolated polybutadiene into the reaction kettle, under nitrogen protection Under the conditions, the temperature was raised to 50°C, stirred and mixed evenly, wherein the stirring speed was 160 rpm, and the stirring time was 20 minutes to obtain a mixture 1;

[0021] Step 2: Add the coupling agent and lauroyl perox...

Embodiment 2

[0023] A tamp paste binder for an aluminum electrolytic cell, comprising the following components in terms of weight components: 12 parts of brominated epoxy resin, 2 parts of antimony trioxide, 1 part of carnauba wax, 5 parts of glycidyl methacrylate 2 parts, titanate coupling agent 2 parts, lauroyl peroxide 2 parts, stearic acid 3 parts, barium stearate 2 parts, phenolated polybutadiene 6 parts.

[0024] The preparation method of the above-mentioned aluminum electrolytic cell tamping paste binder comprises the following steps:

[0025] In step 1, brominated epoxy resin, antimony trioxide, carnauba wax, glycidyl methacrylate, stearic acid, barium stearate and phenolated polybutadiene are added to the reactor, and Under protected conditions, the temperature was raised to 52°C, stirred and mixed evenly, wherein the stirring speed was 180 rpm, and the stirring time was 22 minutes to obtain a mixture 1;

[0026] Step 2: Add the coupling agent and lauroyl peroxide to the mixture ...

Embodiment 3

[0028] A tamping paste binder for an aluminum electrolytic cell, comprising the following components in terms of weight components: 13 parts of brominated epoxy resin, 2 parts of antimony trioxide, 3 parts of carnauba wax, 5 parts of glycidyl methacrylate 3 parts, 3 parts of silane coupling agent, 2 parts of lauroyl peroxide, 3 parts of stearic acid, 2 parts of barium stearate, 7 parts of phenolated polybutadiene.

[0029] The preparation method of the above-mentioned aluminum electrolytic cell tamping paste binder comprises the following steps:

[0030] Step 1, adding brominated epoxy resin, antimony trioxide, carnauba wax, glycidyl methacrylate, stearic acid, barium stearate and phenolated polybutadiene into the reaction kettle, under nitrogen protection Under the conditions, the temperature was raised to 55°C, stirred and mixed evenly, wherein the stirring speed was 180 rpm, and the stirring time was 25 minutes to obtain a mixture 1;

[0031] Step 2: Add the coupling agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com