Spraying-free polyamide resin complex and preparation method thereof

A polyamide resin and compound technology, applied in the field of spray-free polyamide resin compound and its preparation, can solve the problems of weather resistance size change and high temperature yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

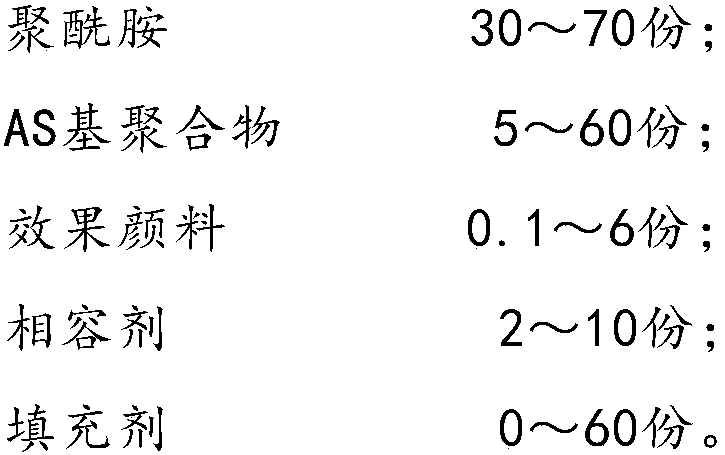

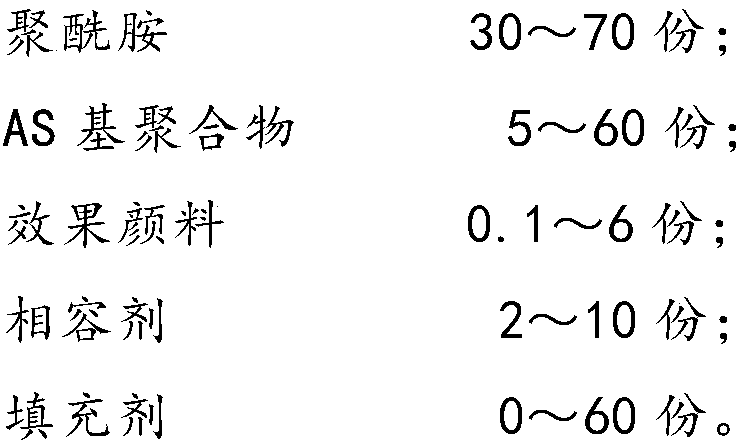

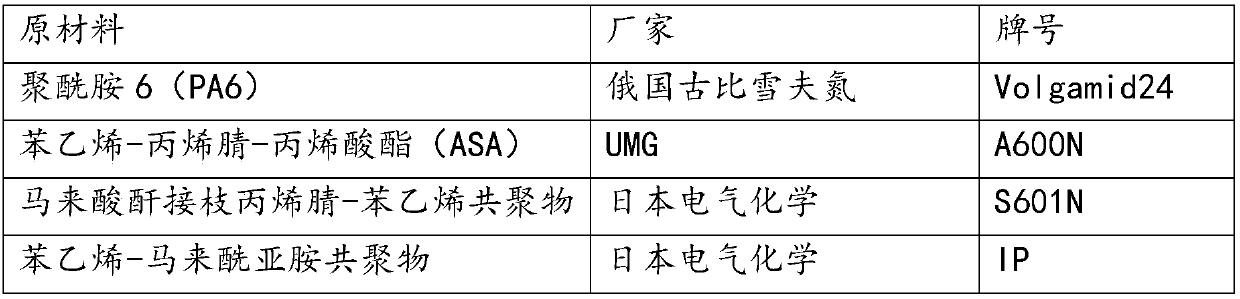

[0096] Step 1: Prepare raw materials according to the following components and parts by weight thereof:

[0097] Polyamide 6 (PA6) 70kg;

[0098] Styrene-acrylonitrile-acrylate (ASA) 12kg;

[0099] Effect pigment 2kg;

[0100] Styrene-maleimide copolymer 5kg;

[0101] Step 2: After mixing the components in step 1, put them into a twin-screw extruder, melt extrude, cool and granulate at the same time, and obtain the product of Example 1.

[0102] Among them, the twin-screw extruder is divided into nine zones, and the temperature of each zone is: the temperature of the first zone is 230°C, the temperature of the second zone is 230°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 230°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zone is 230°C. The temperature in the zone is 240°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 245°C, and the temperature in the ninth zone ...

Embodiment 2

[0104] Step 1: Prepare raw materials according to the following components and parts by weight thereof:

[0105] Polyamide 6 (PA6) 57kg;

[0106] Styrene-acrylonitrile-acrylate (ASA) 20kg;

[0107] Effect pigment 2kg;

[0108] Styrene-maleimide copolymer 5kg;

[0109] Silica 15kg;

[0110] Step 2: After mixing the components in step 1, put them into a twin-screw extruder, melt extrude, cool and granulate at the same time, and obtain the product of Example 2.

[0111] Among them, the twin-screw extruder is divided into nine zones, and the temperature of each zone is: the temperature of the first zone is 230°C, the temperature of the second zone is 230°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 230°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zone is 230°C. The temperature in the zone is 240°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 245°C, and the tempera...

Embodiment 3

[0113] Step 1: Prepare raw materials according to the following components and parts by weight thereof:

[0114] Polyamide 6 (PA6) 41kg;

[0115] Styrene-acrylonitrile-acrylate (ASA) 30kg;

[0116] Effect pigment 3kg;

[0117] Styrene-maleimide copolymer 10kg;

[0119] Step 2: After mixing the components in step 1, put them into a twin-screw extruder, melt extrude, cool and granulate at the same time, and obtain the product of Example 3.

[0120] Among them, the twin-screw extruder is divided into nine zones, and the temperature of each zone is: the temperature of the first zone is 230°C, the temperature of the second zone is 230°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 230°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zone is 230°C. The temperature in the zone is 240°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 245°C, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com