Lead-free solder alloy

A lead-free solder alloy, high-quality technology, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of soldering reliability damage, adverse effects of drop impact resistance, etc., to prevent solder alloys Yellowing, improvement of drop impact resistance, pore suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

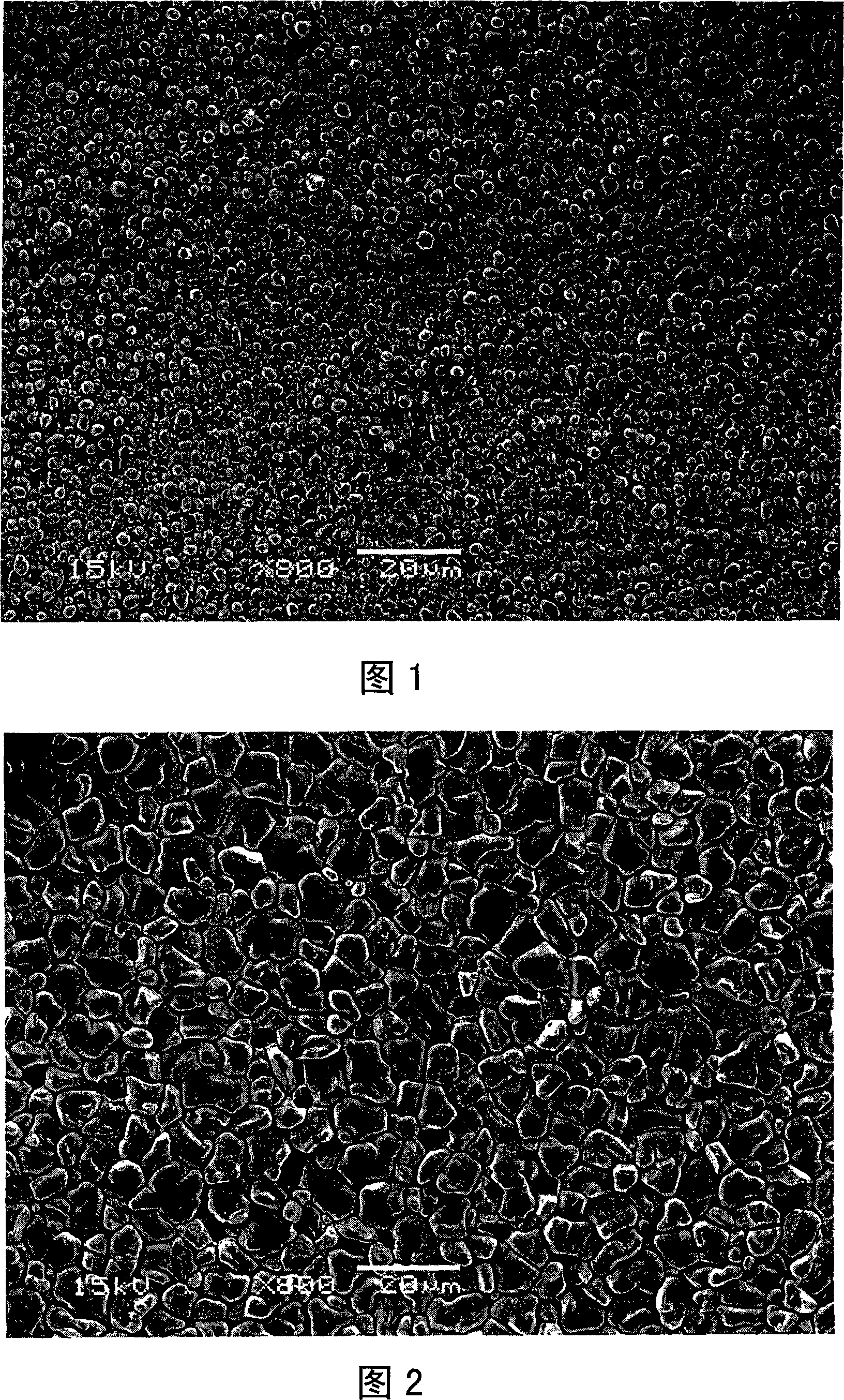

[0042] Solder balls having a diameter of 0.3 mm were fabricated using the solder alloys having the compositions shown in Table 1. Among the solder alloys shown as comparative examples in Table 1, Comparative Examples 1 and 2 exemplify solder alloys having typical compositions described in Patent Documents 1 and 23, respectively. Comparative Examples 3 and 5 exemplify the solder alloy described in Patent Document 3.

[0043] Using these solder balls, the drop impact resistance before and after thermal aging, the thickness of the alloy layer after thermal aging, yellowing due to heating, and generation of voids were investigated by the method described below. These results are combined and shown in Table 1. The heating in the reflow furnace or the constant temperature bath in each test was implemented in air atmosphere.

[0044] (drop impact resistance)

[0045] (1) On electrodes of a CSP having a size of 12×12 mm having 192 electrodes (copper-plated on the surface), flux was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com