Chemical extraction and recovery method for carbon black after waste rubber decomposition

A chemical and waste rubber technology, which is applied in solid solvent extraction, nickel sulfate, alkali metal silicate, etc., can solve the problems of resource waste, industry development restrictions of waste rubber cracking and recycling, increased processing costs and environmental burdens, etc. , to achieve the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

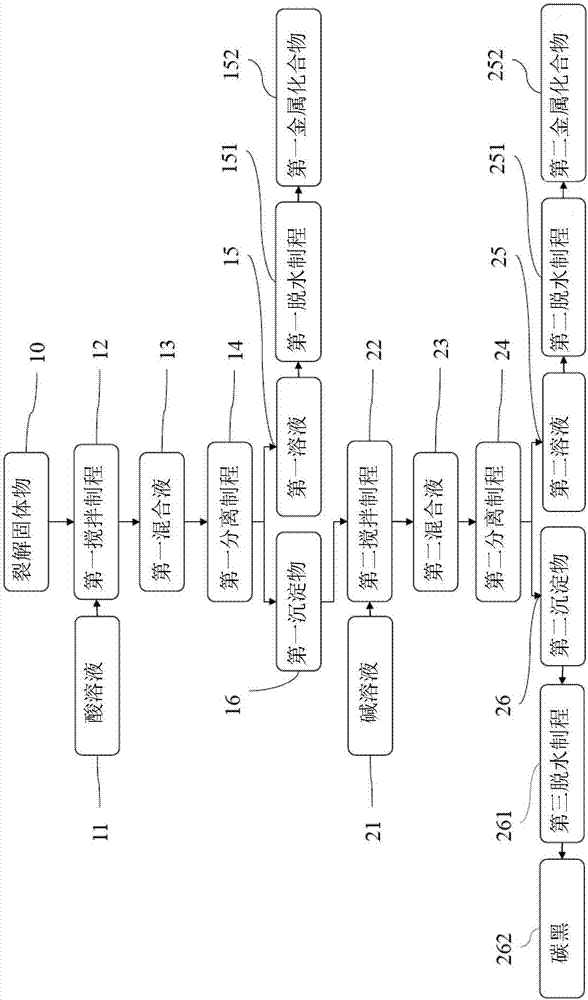

Method used

Image

Examples

Embodiment 1

[0074] Provide 50 grams of pyrolysis solids, measuring about 15.45% ash, which is ground recovered carbon black, which is obtained from recycled waste rubber through a general cracking process.

[0075] An acid solution is provided, which is to provide 1 liter of pure water and add about 10 grams of concentrated sulfuric acid to prepare a 0.1N sulfuric acid solution.

[0076] Slowly place the sulfuric acid solution (acid solution) and the recovered carbon black (cracked solids) into the stirring device, so that the recovered carbon black is completely immersed in the sulfuric acid solution, and continue to stir for 2 hours, and gradually heat up to 70°C at room temperature (section a stirring process) to generate the first mixed solution.

[0077] Stirring is stopped, and the first mixed solution is separated into a first precipitate and a first solution through an extraction process, a precipitation process, and a filtration process (a first separation process).

[0078] Was...

Embodiment 2

[0087] Provide 100 grams of cracked solids, measuring about 15.45% ash, which is ground recovered carbon black, which is obtained from recycled waste rubber through a general cracking process.

[0088] An acid solution is provided, which is to provide 1 liter of pure water and add about 100 grams of concentrated sulfuric acid to prepare a 1N sulfuric acid solution.

[0089] Slowly place the sulfuric acid solution (acid solution) and recovered carbon black (cracked solids) into the stirring device, so that the recovered carbon black is completely immersed in the sulfuric acid solution, and continue to stir for 1 hour, and gradually heat up to 80°C at room temperature (section a stirring process) to generate the first mixed solution.

[0090] Stirring is stopped, and the first mixed solution is separated into a first precipitate and a first solution through an extraction process, a precipitation process, and a filtration process (a first separation process).

[0091] Wash the f...

Embodiment 3

[0100] Provide 50 grams of cracked solids, measuring about 15.45% ash, which is ground recovered carbon black, which is obtained from recycled waste rubber through a general cracking process.

[0101] Provide an acid solution, use the waste reduction equipment washing tower in the cracking process, pass the sulfur dioxide produced in the process through the washing tower, and hydrolyze the sulfur dioxide and water into a sulfuric acid solution, and collect the recovered sulfuric acid solution into the acidification tank. Sulfuric acid solution, the recovered sulfuric acid solution and concentrated sulfuric acid are prepared into 1N, 1 liter sulfuric acid solution.

[0102] Slowly place the sulfuric acid solution (acid solution) and the recovered carbon black (cracked solid) into the stirring device, so that the recovered carbon black is completely immersed in the sulfuric acid solution, and continue to stir for 3 hours, and gradually heat up to 90°C at room temperature (section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com