Resource utilization method of wastewater slag of cobalt and nickel metallurgy

A technology for recycling waste water and slag, applied in chemical instruments and methods, applications, cobalt sulfate and other directions, can solve the problems of enrichment, non-conformity, difficult recycling, etc., and achieve the effect of high purity and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

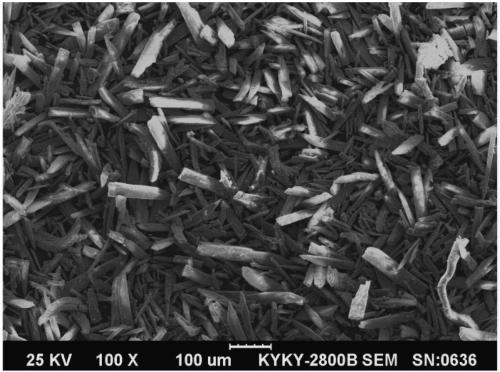

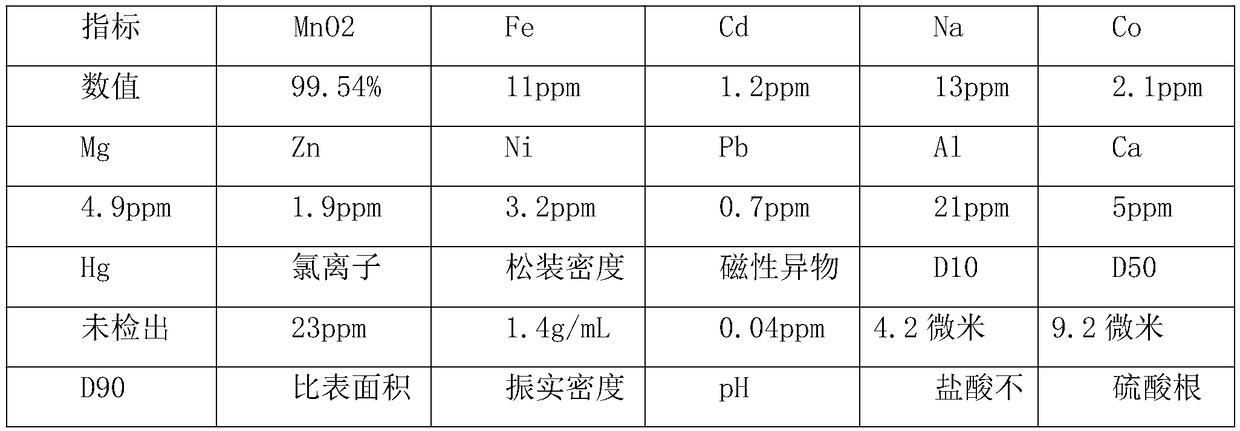

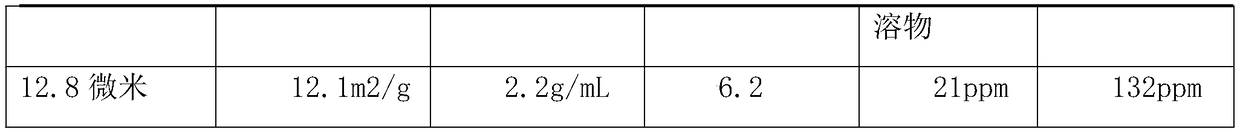

Image

Examples

Embodiment 1

[0042] A method for resource utilization of cobalt-nickel metallurgy waste water slag, comprising the following steps:

[0043] (1) Pretreatment, add water to the waste water and carry out ball milling in a ball mill, then add water for stirring and slurrying, then pour it into an autoclave, at a temperature of 185°C, feed hydrogen to maintain the pressure in the autoclave at 12 Under 1 atmospheric pressure, stir reaction 4.5 hours, then cool down and release pressure;

[0044] (2) The reacted material obtained in step (1) is carried out by gravity sorting with a gravity separator, and the metal particles and the slurry are sorted out, and the metal particles are separated by magnetic separation, and the nickel-cobalt-iron powder and copper The copper powder is separated, the copper powder is smelted to obtain a copper anode plate, and then the cathode copper is obtained through electrolytic refining, and the nickel-cobalt-iron powder is added to the phosphoric acid solution t...

Embodiment 2

[0062] A method for resource utilization of cobalt-nickel metallurgy waste water slag, comprising the following steps:

[0063] (1) Pretreatment, add water to the waste water and carry out ball milling in a ball mill, then add water for stirring and slurrying, then pour into the autoclave, at a temperature of 156 ° C, feed hydrogen to maintain the pressure in the autoclave at 11 Under 1 atmospheric pressure, stir reaction 4.5 hours, then cool down and release pressure;

[0064] (2) The reacted material obtained in step (1) is carried out by gravity sorting with a gravity separator, and the metal particles and the slurry are sorted out, and the metal particles are separated by magnetic separation, and the nickel-cobalt-iron powder and copper The copper powder is separated, the copper powder is smelted to obtain a copper anode plate, and then the cathode copper is obtained through electrolytic refining, the nickel-cobalt-iron powder is added to the phosphoric acid solution to di...

Embodiment 3

[0082] A method for resource utilization of cobalt-nickel metallurgy waste water slag, comprising the following steps:

[0083] (1) Pretreatment, add water to the waste water and carry out ball milling in a ball mill, then add water for stirring and slurrying, then pour it into an autoclave, at a temperature of 165°C, feed hydrogen to maintain the pressure in the autoclave at 12 Under 1 atmospheric pressure, stir reaction 4.2 hours, then cool down and release pressure;

[0084] (2) The reacted material obtained in step (1) is carried out by gravity sorting with a gravity separator, and the metal particles and the slurry are sorted out, and the metal particles are separated by magnetic separation, and the nickel-cobalt-iron powder and copper The copper powder is separated, the copper powder is smelted to obtain a copper anode plate, and then the cathode copper is obtained through electrolytic refining, the nickel-cobalt-iron powder is added to the phosphoric acid solution to di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com