Recycling method of waste ternary battery material lithium nickel cobalt manganese

A ternary battery, lithium-nickel-cobalt-manganese technology, which is applied in the field of waste ternary battery recycling and processing, can solve the problems of high energy consumption and water resources, reduce acid and alkali consumption, increase recovery rate, and metal yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Raw materials: Waste ternary battery recycling powder model 523, negative electrode powder content 40%, material weight 1000KG.

[0053] Table 1 Composition list of waste ternary batteries

[0054] element Ni co mn Li Cu Al Fe content(%) 20.0 8.0 12.05 4.8 1.0 0.5 0.1

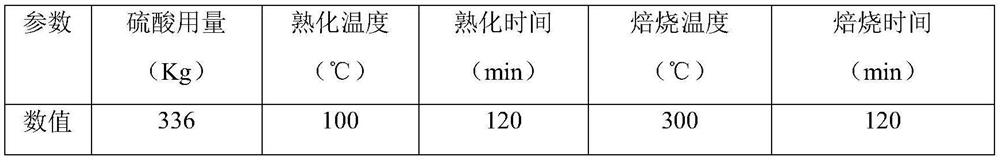

[0055] Sulfuric acid ripening transition to reduction roasting: see Table 2 for process parameters.

[0056] Table 2 Example 1 Sulfuric acid ripening conversion reduction roasting process parameter table

[0057]

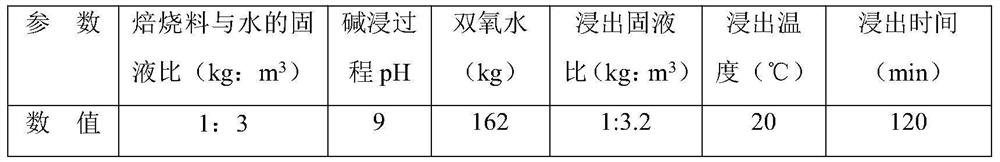

[0058] Lithium leaching by alkaline oxidation: See Table 3 for process parameters.

[0059] Table 3 Example 1 Alkaline Oxidation Lithium Immersion Parameter Table

[0060]

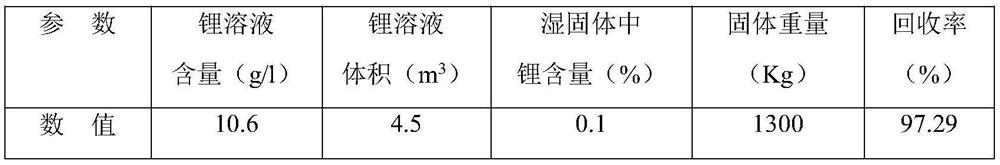

[0061] Filtration and washing to obtain lithium sulfate solution and lithium recovery rate are shown in Table 4.

[0062] Table 4 Example 1 Alkaline oxidation lithium leaching result table

[0063]

[0064] Slight acid leaching of nickel and cobalt: see Table 5 for proces...

Embodiment 2

[0077] Raw materials: Waste ternary battery recycling powder model 622, negative electrode powder content 40%, material weight 1000KG.

[0078] Table 9 Composition of waste ternary batteries

[0079] element Ni co mn Li Cu Al Fe content(%) 19.8 6.6 9.9 4.75 1.2 0.7 0.15

[0080] Sulfuric acid ripening transition to reduction roasting: see Table 10 for the process parameters.

[0081] Table 10 Example 2 Sulfuric acid ripening conversion reduction roasting process parameter list

[0082]

[0083] Lithium leaching by alkaline oxidation: See Table 11 for process parameters.

[0084] Table 11 Example 2 Alkaline Oxidation Lithium Immersion Parameter Table

[0085]

[0086] See Table 12 for filtering and washing lithium sulfate solution and lithium recovery rate.

[0087] Table 12 Example 2 Alkaline oxidation lithium leaching result table

[0088]

[0089] Slight acid leaching of nickel and cobalt: see Table 13 for process parameter...

Embodiment 3

[0102] Raw materials: Waste ternary battery recycling powder type 111, negative electrode powder content 40%, material weight 1000KG.

[0103] Table 17 Composition of waste ternary batteries

[0104] element Ni co mn Li Cu Al Fe content(%) 11.0 11.0 11.0 4.6 1.5 0.4 0.3

[0105] Sulfuric acid ripening transition to reduction roasting: See Table 18 for process parameters.

[0106] Table 18 Example 3 sulfuric acid aging conversion reduction roasting process parameter list

[0107]

[0108] Lithium leaching by alkaline oxidation: See Table 19 for process parameters.

[0109] Table 19 Example 3 Alkaline Oxidation Lithium Immersion Parameter Table

[0110]

[0111] See Table 20 for filtering and washing lithium sulfate solution and lithium recovery rate.

[0112] Table 20 Example 3 Alkaline Oxidation Lithium Immersion Result Table

[0113]

[0114] Slight acid leaching of nickel and cobalt: see Table 21 for process parameters.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com