Power lithium ion battery all metal recycling and cyclic utilizing method

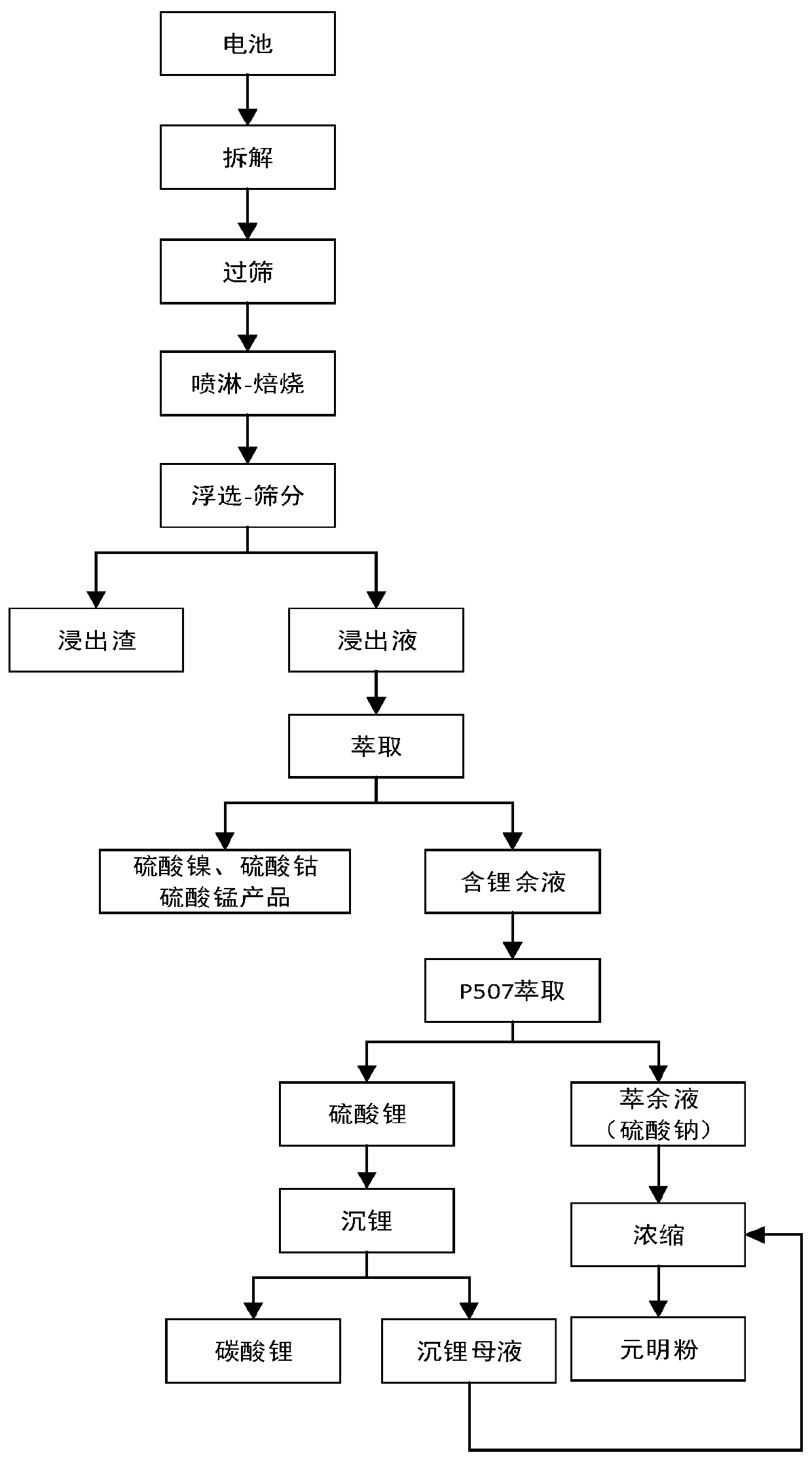

A lithium-ion battery and all-metal technology, which is applied in the field of all-metal recycling of power lithium-ion batteries, can solve problems such as incomplete lithium precipitation, difficulty in realizing full recovery of lithium-ion batteries, and products that cannot meet battery-grade standards, and achieve recycling The effect of high rate, efficient recovery and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take the used lithium-ion battery, put the battery into the crusher with a lift and a conveyor belt, crush the battery to 1-2.5mm, and then sieve it with a 100-mesh vibrating sieve. Contains battery electrode powder, carbon powder, copper foil and aluminum pellets. The crushed undersize is passed through a 200-mesh sieve again to separate the battery pole powder, carbon powder, aluminum particles and copper foil. The oversize is copper foil, and the undersize is battery pole powder, carbon powder, and aluminum particles. The undersize is sprayed with water, and the water content of the material after spraying is 5%, and then roasted in a carbonization furnace, the roasting temperature is 550°C, and the roasting time is 0.5h, flotation, sieving, and the oversize and undersize are obtained . The oversieve is aluminum-containing material, and the undersieve is battery pole powder.

[0040] Take the battery electrode powder and make a slurry with a solid-to-liquid ratio of ...

Embodiment 2

[0053] Take the used lithium-ion battery, put the battery into the crusher with a lift and a conveyor belt, crush the battery to 4-9mm, and then sieve it with an 80-mesh vibrating sieve. Battery pole powder, carbon powder, copper foil and aluminum pellets. The crushed undersize is sieved again to separate the battery pole powder, carbon powder, aluminum particles and copper foil, the oversize is copper foil, and the undersize is battery pole powder, carbon powder and aluminum particles. The undersize is sprayed with water, and the water content of the material after spraying is 5%, and then roasted in a carbonization furnace, the roasting temperature is 520°C, the roasting time is 1.5h, flotation, sieving, and the oversize and undersize are obtained . The oversieve is aluminum-containing material, and the undersieve is battery pole powder.

[0054] Take the battery electrode powder and mix it with a solid-to-liquid ratio of 1:4. After the slurry is mixed, put the slurry into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com