Method for recycling valuable metals in lithium battery through wet process

A technology for recovering valuable metals and lithium, applied in battery recovery, recycling technology, recycling by waste collectors, etc., can solve the problems of high metal loss rate, time-consuming and laborious, long extraction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

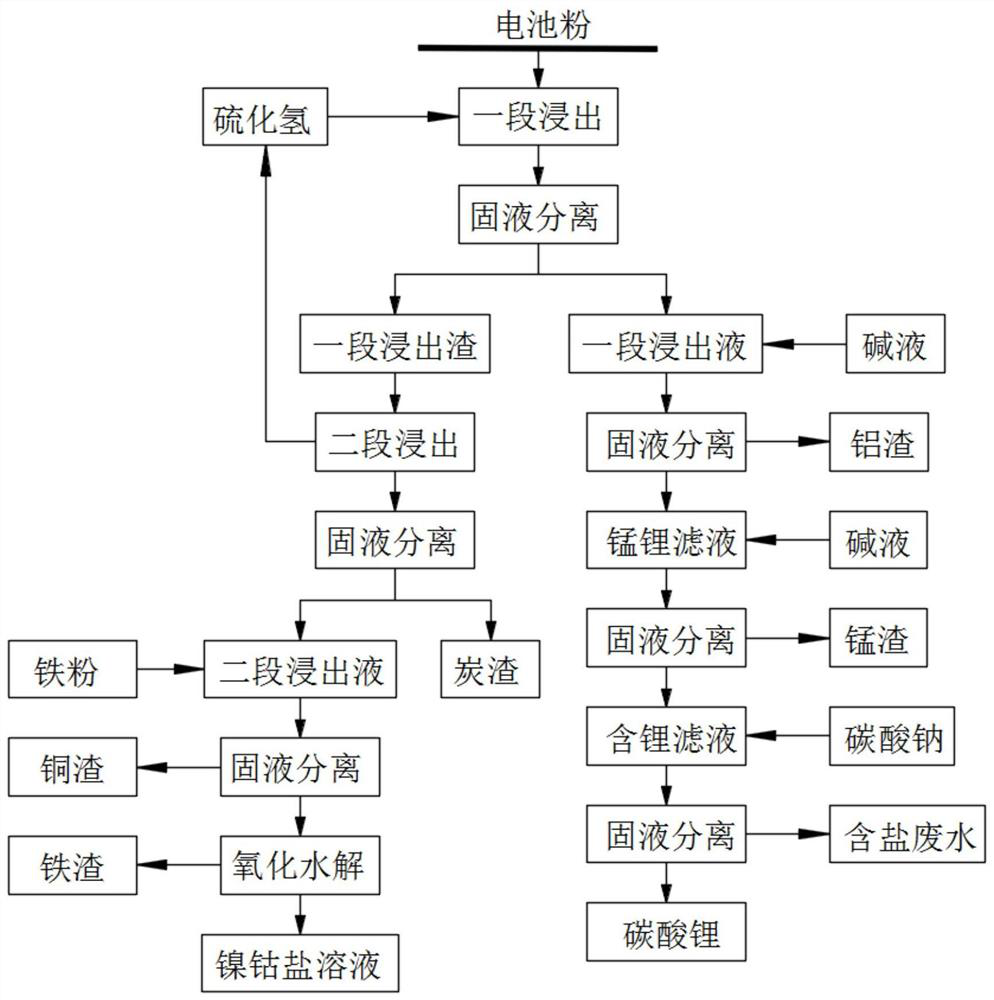

[0032] A method of wet recovery of valuable metals in lithium batteries, with reference to figure 1 , the specific process is:

[0033] The contents of each metal in waste battery powder are: nickel 16.76%, cobalt 10.33%, manganese 7.52%, lithium 4.01%, iron 1.13%, aluminum 1.28%, copper 1.63%. Valuable metals can be recovered through the following steps:

[0034] First, leaching 100g of waste lithium battery powder collected in a sulfuric acid solution with hydrogen sulfide gas, the solid-liquid ratio is controlled at 250g / L, the reaction temperature is 20°C, the pH is 3.0, and the pressure is 3MPa. After 7 hours of reaction , through solid-liquid separation, to obtain L first stage leaching residue and 400m first stage leachate, and process them respectively;

[0035] (1) One section of leaching solution produces lithium carbonate:

[0036] ① Add sodium hydroxide to the first-stage leaching solution to adjust the pH to 5.0-5.5, and separate solid-liquid to obtain manganese...

Embodiment 2

[0045] A method for wet recovery of valuable metals in lithium batteries, the specific process is:

[0046] The contents of each metal in waste battery powder are: nickel 16.76%, cobalt 10.33%, manganese 7.52%, lithium 4.01%, iron 1.13%, aluminum 1.28%, copper 1.63%. Valuable metals can be recovered through the following steps:

[0047] First, leaching 100g of waste lithium battery powder collected in a sulfuric acid solution with hydrogen sulfide gas, the solid-liquid ratio is controlled at 250g / L, the reaction temperature is 60°C, the pH is 3.0, and the pressure is 6MPa. After 7 hours of reaction , through solid-liquid separation, one section of leach residue and 400mL of one section of leachate were obtained, and they were treated separately;

[0048] (1) One section of leaching solution produces lithium carbonate:

[0049] ① Add sodium hydroxide to the first-stage leaching solution to adjust the pH to 5.0-5.5, and separate solid-liquid to obtain manganese-lithium filtrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com