Recovery method for valuable metal in waste nickel-cobalt-manganese ternary lithium batteries

A ternary lithium battery, recycling method technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problems of low recycling rate, insufficient recycling process design, poor purity of recycled products, etc., and achieve high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Discharge the recovered waste nickel-cobalt-manganese ternary lithium batteries first, and release the remaining power to avoid explosion or combustion during the crushing process. After crushing, the crushed material is carbonized at high temperature in a carbonization furnace to consume the organic matter, so that the remainder is mainly some metal elements. After carbonization, it is crushed again to make the electrode material into a powder, and then through wind selection, the powder selected by wind is mainly electrode material (hereinafter referred to as ternary black powder), which is used for the next step of processing, while the lithium battery The steel shell and the like become granular and can be recycled directly after being separated from the powder.

[0043] Ternary black powder test.

[0044] 1. Leaching:

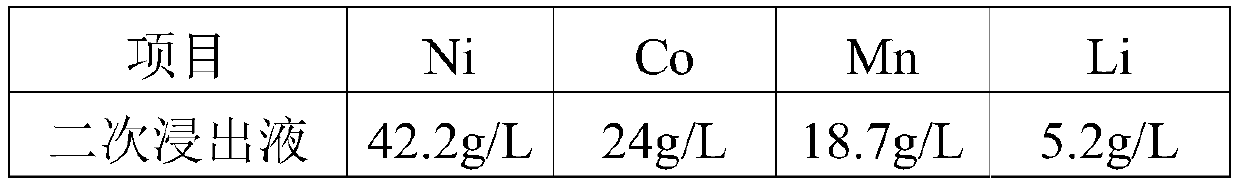

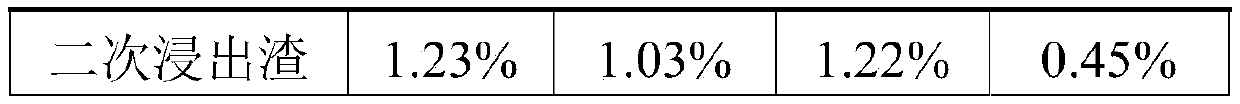

[0045] 1. Take 200 grams of ternary black powder, and the composition test is shown in Table 1.

[0046] Table 1

[0047] Ni co mn...

Embodiment 2

[0091] Discharge the recovered waste nickel-cobalt-manganese ternary lithium batteries first, and release the remaining power to avoid explosion or combustion during the crushing process. After crushing, the crushed material is carbonized at high temperature in a carbonization furnace to consume the organic matter, so that the remainder is mainly some metal elements. After carbonization, it is crushed again to make the electrode material into a powder, and then through wind selection, the powder selected by wind is mainly electrode material (hereinafter referred to as ternary black powder), which is used for the next step of processing, while the lithium battery The steel shell and the like become granular and can be recycled directly after being separated from the powder.

[0092] Ternary black powder test.

[0093] 1. Leaching:

[0094] 1. Take 200 grams of ternary black powder, and the composition test is shown in Table 12.

[0095] Table 12

[0096] Ni co ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com