Grading recovery method for waste ternary lithium battery

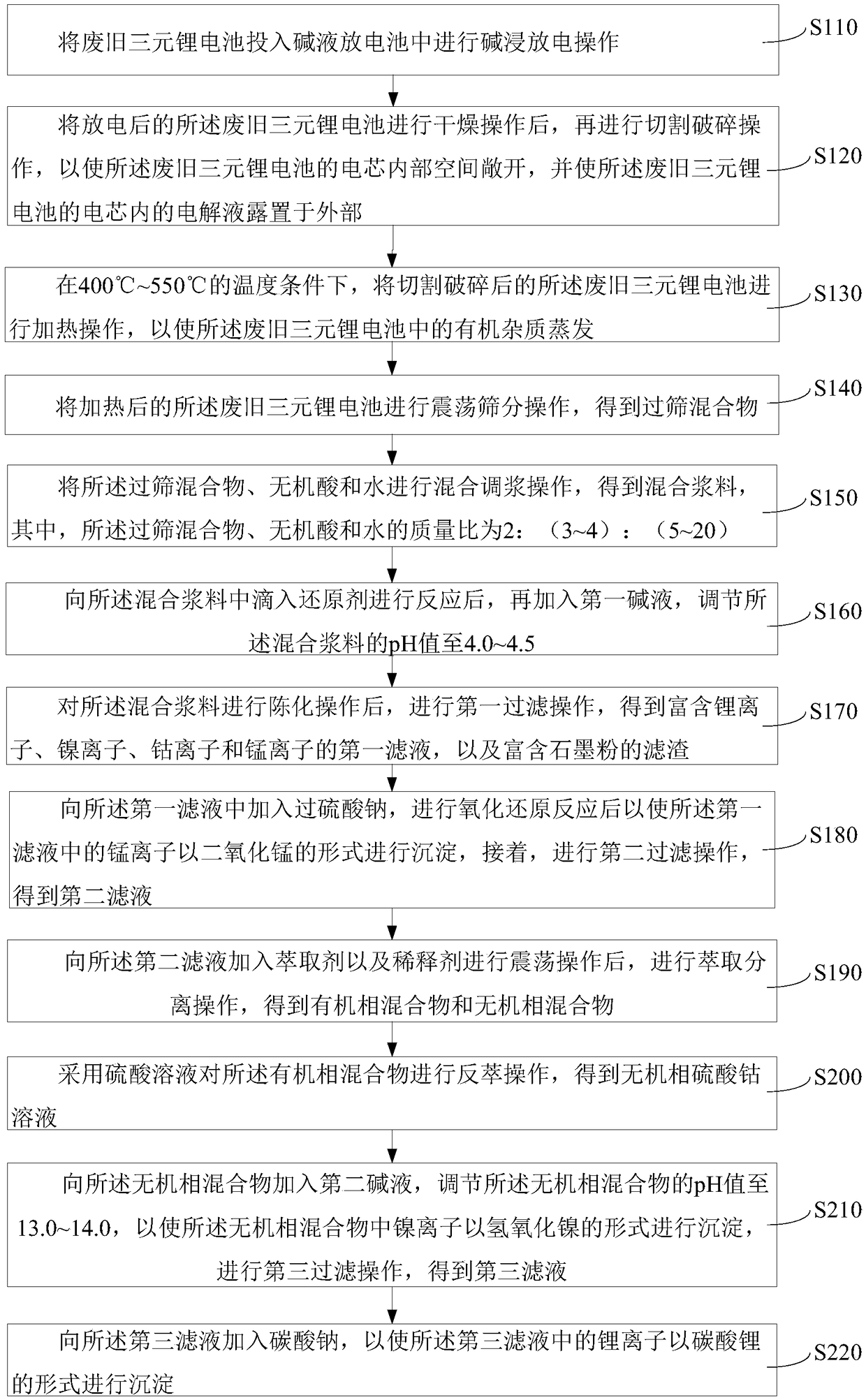

A ternary lithium battery, recycling method technology, applied in battery recycling, recycling technology, lithium carbonate;/acid carbonate and other directions, can solve the problems of multiple chemical reagents, cobalt loss, unfavorable extraction and separation, etc. Achieve the effect of improving the extraction recovery rate, facilitating recycling and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Put the waste ternary lithium battery into an alkaline discharge battery containing a lithium hydroxide solution with a hydroxide concentration of 0.5mol / L for alkaline immersion discharge operation, wherein the alkaline immersion time is 20h;

[0089] After the discharged waste ternary lithium battery is naturally air-dried, it is sent to the cutting machine, and the cutting and crushing operation is carried out in a closed and negative pressure environment, so that the internal space of the battery core of the waste ternary lithium battery is opened, and the waste ternary lithium battery The electrolyte in the battery cell of the lithium battery is exposed to the outside; at the same time, the waste gas generated during the cutting and crushing process is passed into a cold trap at -10°C, in which the cold trap is also connected to a container with a molar concentration of 1mol / L. Tail gas absorption device for NaOH solution;

[0090] Under the temperature condition o...

Embodiment 2

[0101] Put the waste ternary lithium battery into an alkaline discharge battery containing a sodium hydroxide solution with a hydroxide concentration of 1.0mol / L for alkaline immersion discharge operation, wherein the time of alkali immersion is 50h;

[0102] After the discharged waste ternary lithium battery is naturally air-dried, it is sent to the cutting machine, and the cutting and crushing operation is carried out in a closed and negative pressure environment, so that the internal space of the battery core of the waste ternary lithium battery is opened, and the waste ternary lithium battery The electrolyte in the battery cell of the lithium battery is exposed to the outside; at the same time, the waste gas generated during the cutting and crushing process is passed into a -8°C cold trap, and the cold trap is connected behind the cold trap to accommodate a molar concentration of 3mol / L. Tail gas absorption device for NaOH solution;

[0103] At a temperature of 450°C, the ...

Embodiment 3

[0114] Put the waste ternary lithium battery into the alkaline discharge battery containing potassium hydroxide solution with a hydroxide concentration of 3.0mol / L for alkaline immersion discharge operation, wherein the time of alkaline immersion is 240h;

[0115] After the discharged waste ternary lithium battery is naturally air-dried, it is sent to the cutting machine, and the cutting and crushing operation is carried out in a closed and negative pressure environment, so that the internal space of the battery core of the waste ternary lithium battery is opened, and the waste ternary lithium battery The electrolyte in the battery cell of the lithium battery is exposed to the outside; at the same time, the waste gas generated during the cutting and crushing process is passed into a cold trap at -5°C, in which the cold trap is connected to a container with a molar concentration of 5mol / L. Tail gas absorption device for NaOH solution;

[0116] At a temperature of 550°C, the cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com