Wall-face dry-hanging system of large metal aluminum sheet

A metal aluminum, dry-hanging technology, applied in covering/lining, building, building structure, etc., to achieve the effect of not easy to deform, simple operation and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

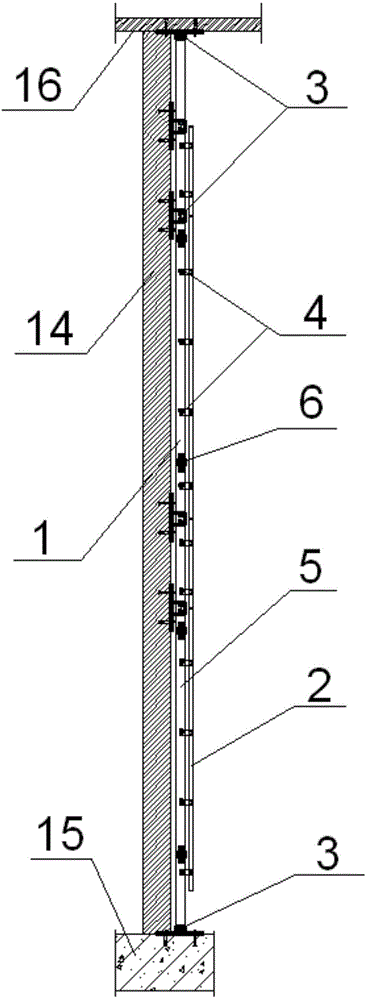

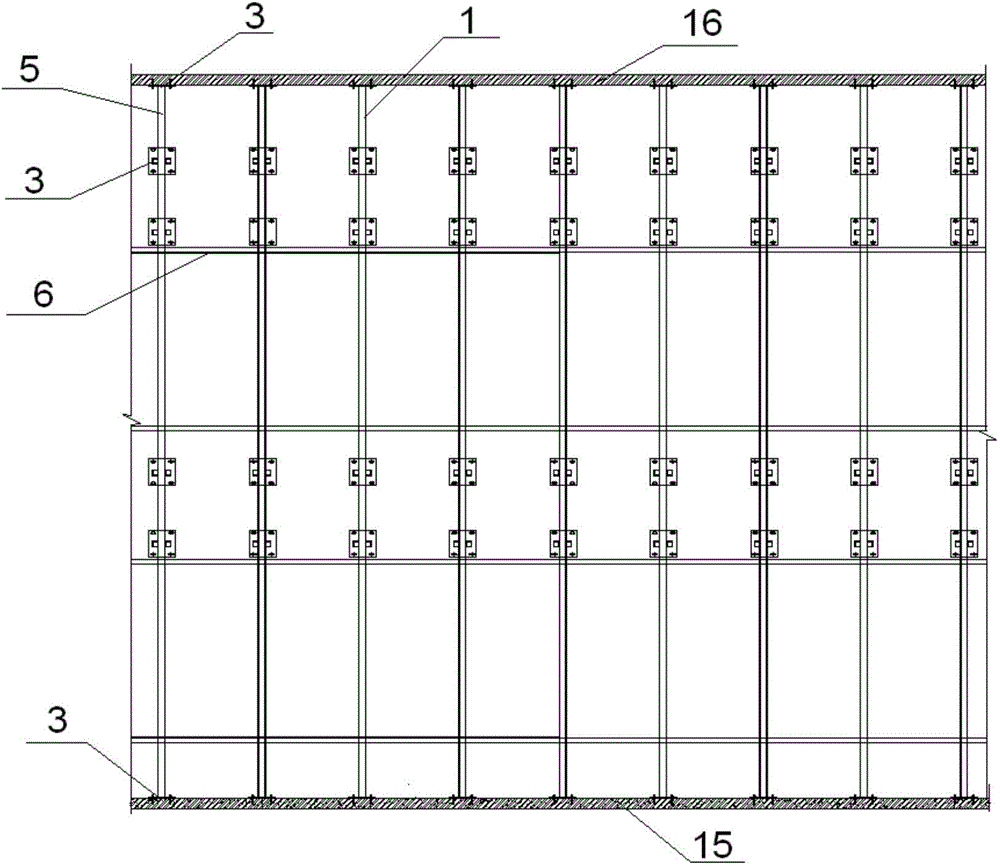

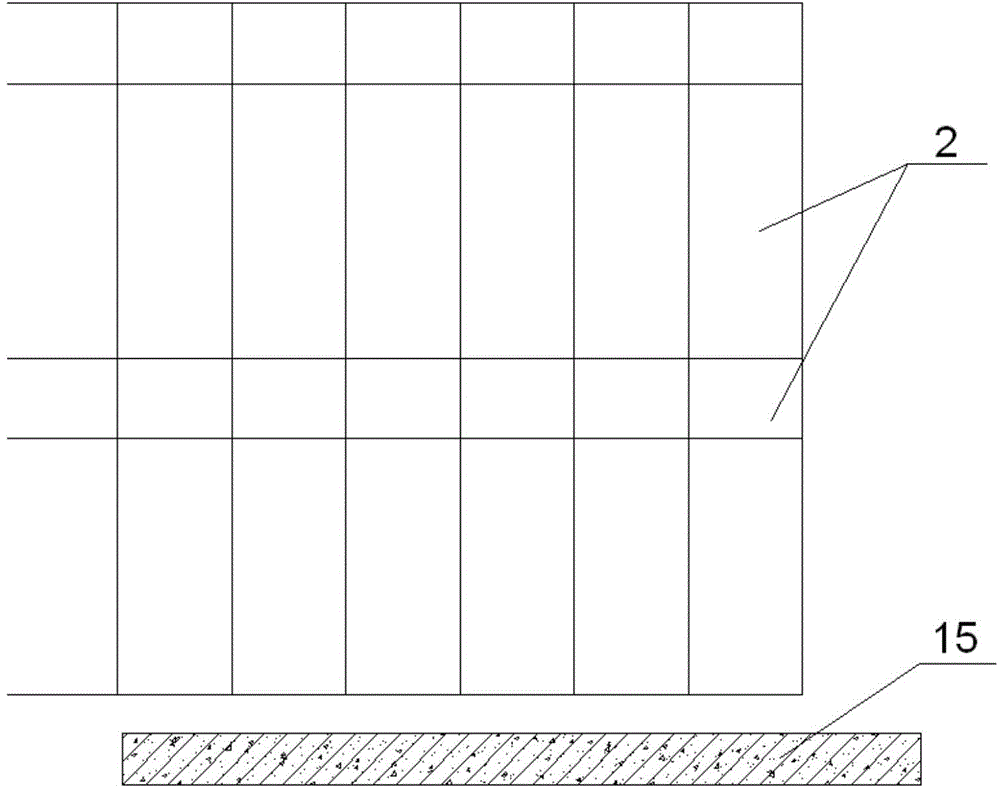

[0026] Such as figure 1 A dry-hanging system for a large plate metal aluminum plate wall is shown, including a steel bracket 1, an aluminum plate 2 and a bracket fixing device 3; the steel bracket 1 is fixed on the wall 14 through several bracket fixing devices 3, and the steel bracket 1 is also passed through The fixing device 3 is fixedly connected with the ground 15 and the ceiling 16 respectively; the aluminum plate 2 is connected with the steel bracket 1 by the limit support of the steel buckle 4 . Due to the sheet shape of the aluminum plate, if the traditional welding method is used to install the aluminum plate on the wall, there will be defects such as insufficient precision, fire hazards, serious labor costs, high waste generation rate, and low process efficiency. The device in the present invention is adopted on the wall The steel bracket is installed on the body, and the steel bracket is used as the installation plane of the aluminum plate, which is easy to assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com