Process for producing high-purity potassium chloride

A production process, potassium chloride technology, applied in the field of purification of alkali metal halides, can solve the problems of high recovery rate, low recovery rate, high cost, etc., and achieve the effects of low production cost, white color and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

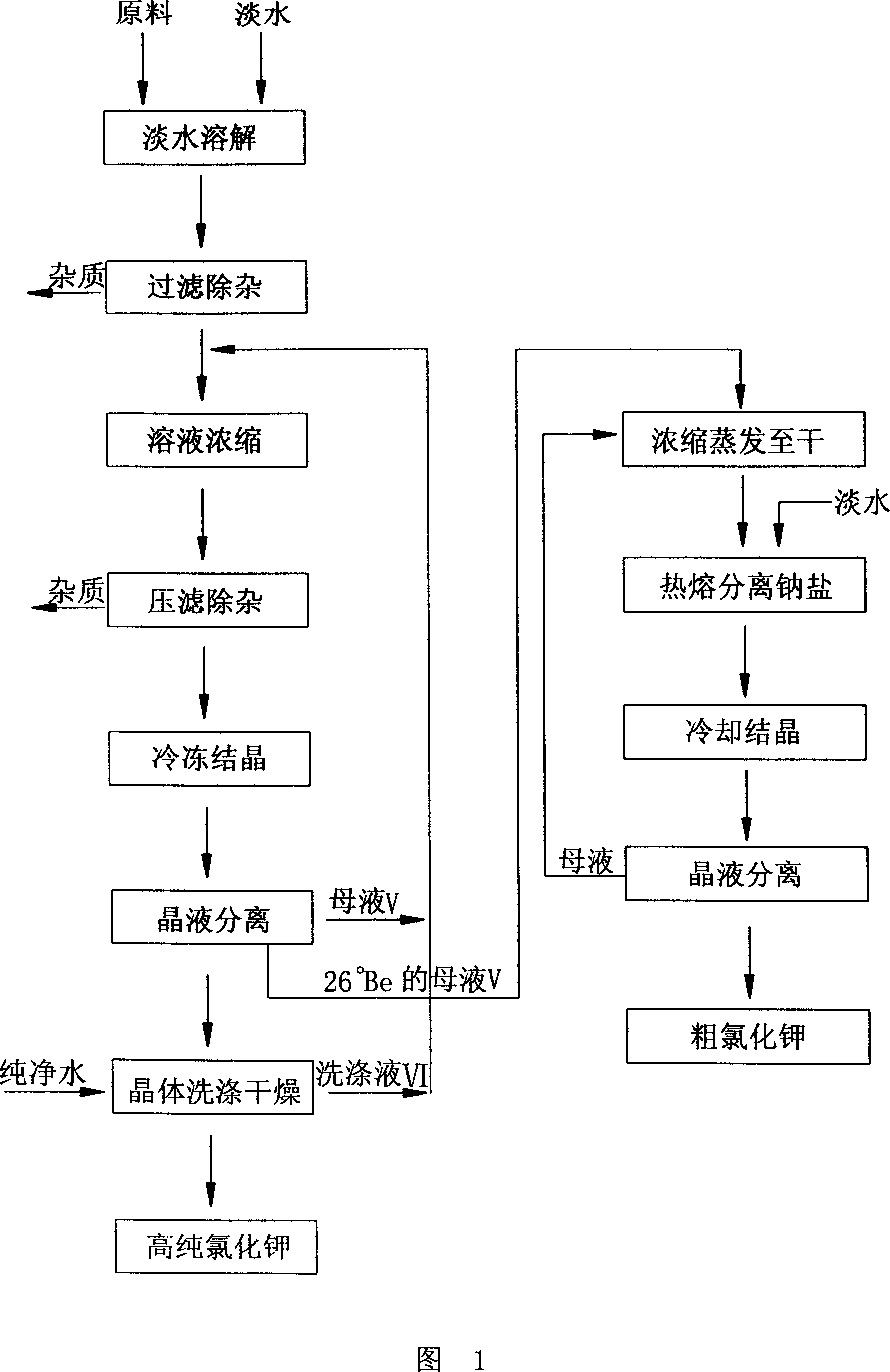

[0041] Embodiment 1 As shown in Figure 1, the production process of high-purity potassium chloride, with the purity of 89.96% potassium chloride fertilizer as raw material, the physical and chemical indicators of this potassium chloride fertilizer are: sodium chloride content 1.22%, magnesium chloride content 0.43%, sulfuric acid Calcium content 3.72%, water insoluble matter 4.68%)

[0042] The production process steps of this high-purity Repone K are as follows:

[0043] (1) the potassium chloride that takes by weighing 1000kg is 89.96% and is put in 4000L container, adds 2350Kg fresh water and fully stirs to obtain saturated solution I;

[0044] (2) filter potassium chloride saturated solution I with a filter press, remove insolubles, obtain saturated clear liquid II 2940.6Kg of potassium chloride;

[0045] (3) when potassium chloride saturated clear liquid II is concentrated to 100 DEG C with an evaporator, the Baume degree is equal to 27 ° Be when crystals are separated o...

Embodiment 2

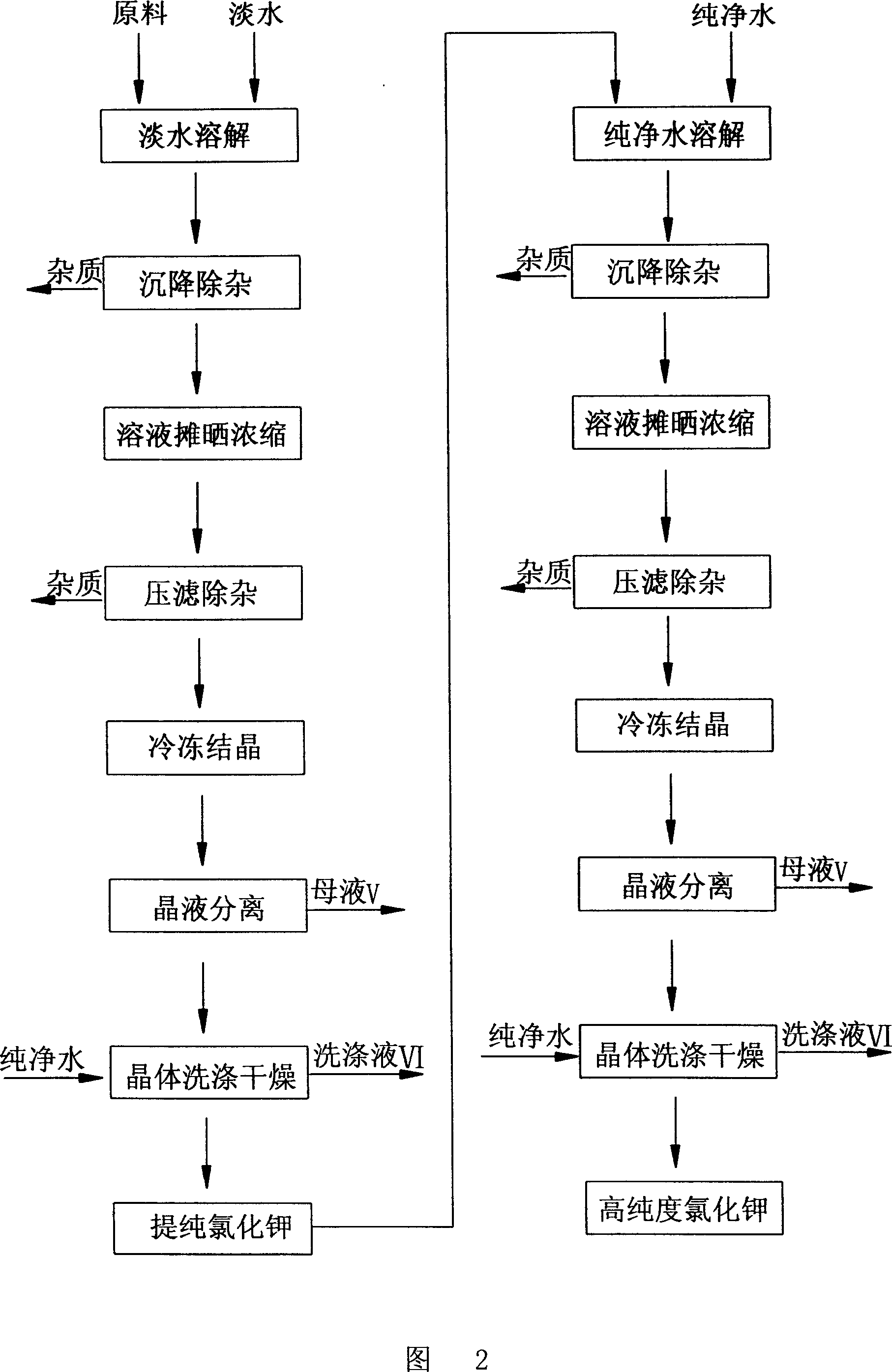

[0052] Example 2 As shown in Figure 2, the production process of high-purity potassium chloride uses crude potassium chloride with a purity of 45.19% as raw material. The physical and chemical performance indicators of this potassium chloride are: sodium chloride content 11.22%, magnesium chloride content 0.63% , calcium sulfate content 23.61%, water insoluble 19.37%.

[0053] The production process steps of this high-purity Repone K are as follows:

[0054] (1) Take by weighing 10kg of crude potassium chloride with a purity of 45.19% and put it in a 40L container, add 11.96Kg of fresh water and fully stir to obtain saturated solution I;

[0055] (2) The saturated solution I of potassium chloride is naturally settled in a settling tank, and the insolubles are removed to obtain the clarified solution II 15.34Kg of potassium chloride;

[0056] (3) then the potassium chloride saturated clear liquid II is naturally sun-dried and concentrated to a liquid temperature of 28° C. (at ...

Embodiment 3

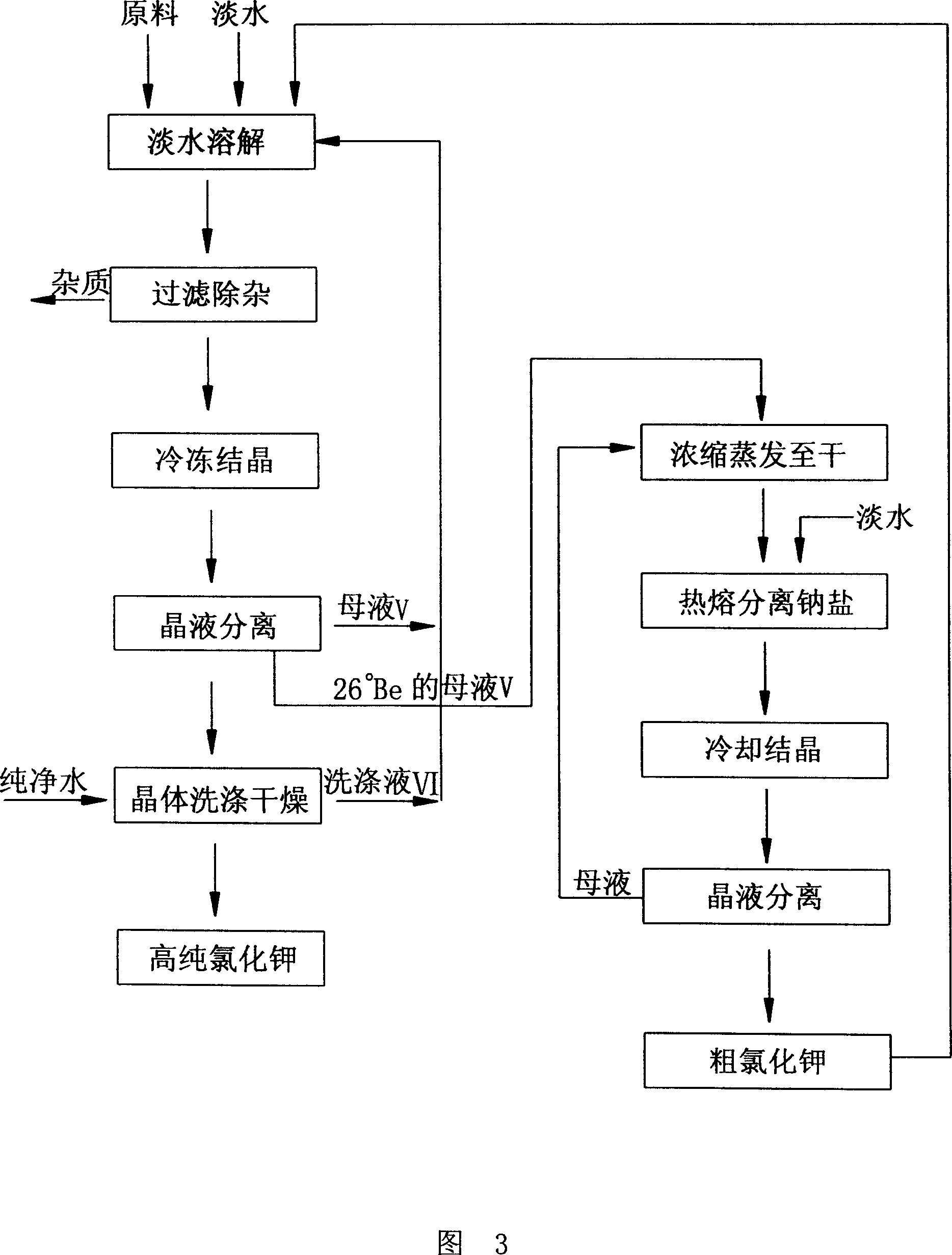

[0061] Example 3 As shown in Figure 3, the production process of high-purity potassium chloride uses crude potassium chloride with a purity of 73.11% as raw material. The physical and chemical performance indicators of this potassium chloride are: sodium chloride content 5.63%, magnesium chloride content 0.67% , calcium sulfate content 12.15%, water insoluble matter 8.44%.

[0062] The production process steps of this high-purity Repone K are as follows:

[0063] (1) Take 1000Kg of crude potassium chloride with a purity of 73.11% and 1360Kg of fresh water and heat and mix it in a 4000L agitator with a capacity of 4000L. Fully stir the solution so that the solution is clear at 100° C. and the Baume concentration is 27° Be to obtain solution I;

[0064] (2) The saturated solution I is pumped into a filter press to filter, and after separating all water insolubles, a saturated clear solution II 1959Kg is obtained;

[0065] (3) The supersaturated solution II that has filtered out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com