Ultraviolet-curable water-based colored paint composition

A colored coating, ultraviolet technology, applied in the direction of coating, etc., can solve the problem that the quality of the coating cannot be guaranteed, the monomer or oligomer cannot be effective, the coating film is not dry or semi-drying, etc., to achieve good scratch resistance, Low cost, good abrasion and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

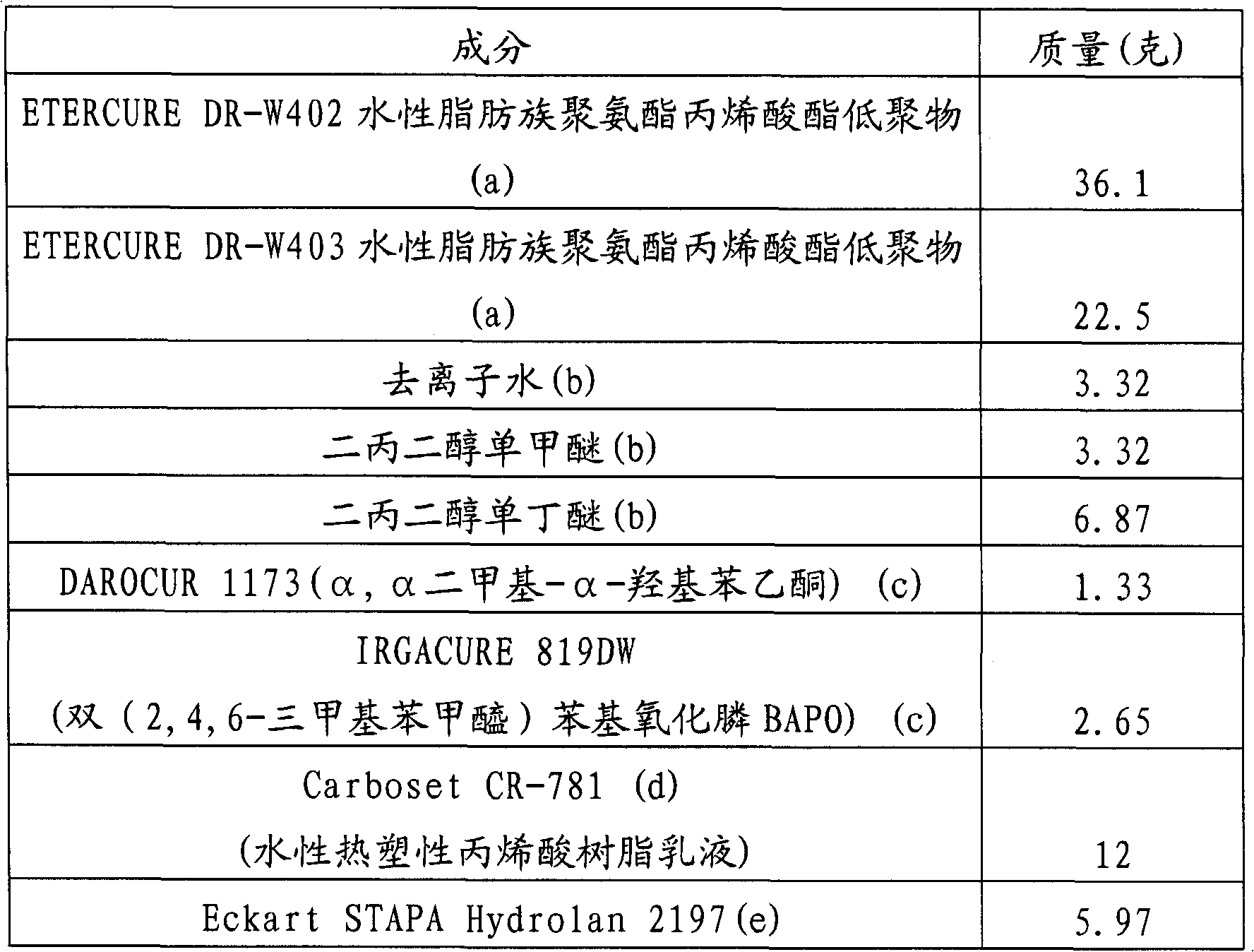

[0066] Table 1

[0067]

[0068]

[0069] Add the diluent (deionized water / ethanol = 1 / 1 (volume ratio)) to the Iwata cup of the composition obtained above for about 10 seconds, spray it on the plastic substrate with an air spray gun, and then carry out 5 minutes in an oven at 60°C. ~10 minutes of pre-bake, then, through the medium pressure mercury lamp (800mJ / cm 2 ) for exposure. Then, the substrate with the coating film after exposure is subjected to a physical property test.

[0070] The results of the physical property test are as follows:

[0071] Film thickness: 8~15μm

[0072] Adhesion between coating film and substrate: 100 / 100

[0073] Coating film hardness: ≥H

[0074] Coating gloss: 70

[0075] Chemical resistance of the coating film: pass (no scratches on the appearance, no peeling off)

[0076] Coating film heat resistance: pass

[0077] Appearance: flat, with a silver semi-gloss effect

Embodiment 2

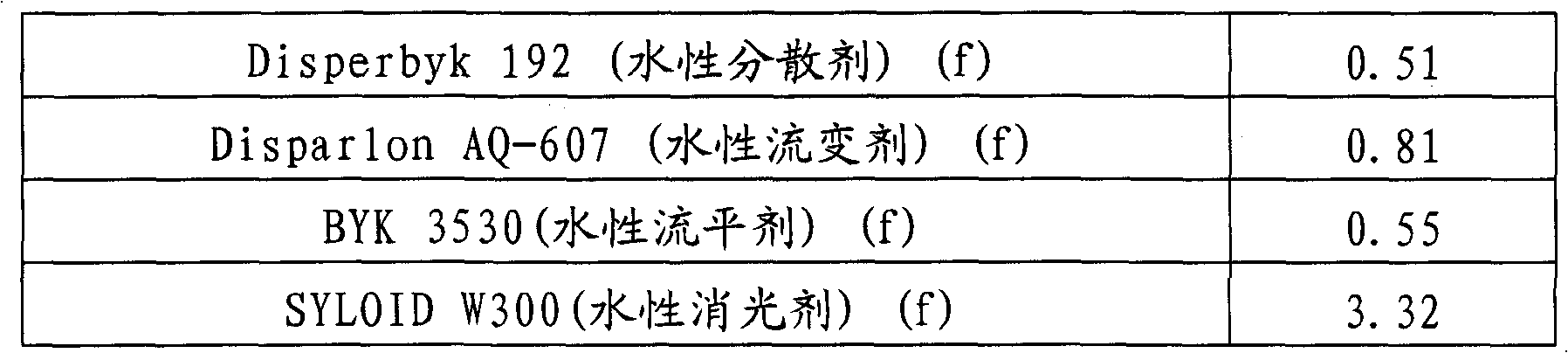

[0079] Table 2

[0080]

[0081]

[0082] Add the diluent (deionized water / ethanol = 1 / 1 (volume ratio)) to the Iwata cup of the composition obtained above for about 10 seconds, spray it on the plastic substrate with an air spray gun, and then carry out 5 minutes in an oven at 60°C. ~10 minutes of pre-bake, then, through the medium pressure mercury lamp (800mJ / cm 2 ) for exposure. Then, the substrate with the coating film after exposure is subjected to a physical property test.

[0083] The results of the physical property test are as follows:

[0084] Film thickness: 10-15μm

[0085] Adhesion between coating film and substrate: 100 / 100

[0086] Coating film hardness: ≥F

[0087] Coating film gloss: 80

[0088] Chemical resistance of the coating film: pass (no scratches on the appearance, no peeling off)

[0089] Coating film heat resistance: pass

[0090] Appearance: flat, with blue full light effect.

Embodiment 3

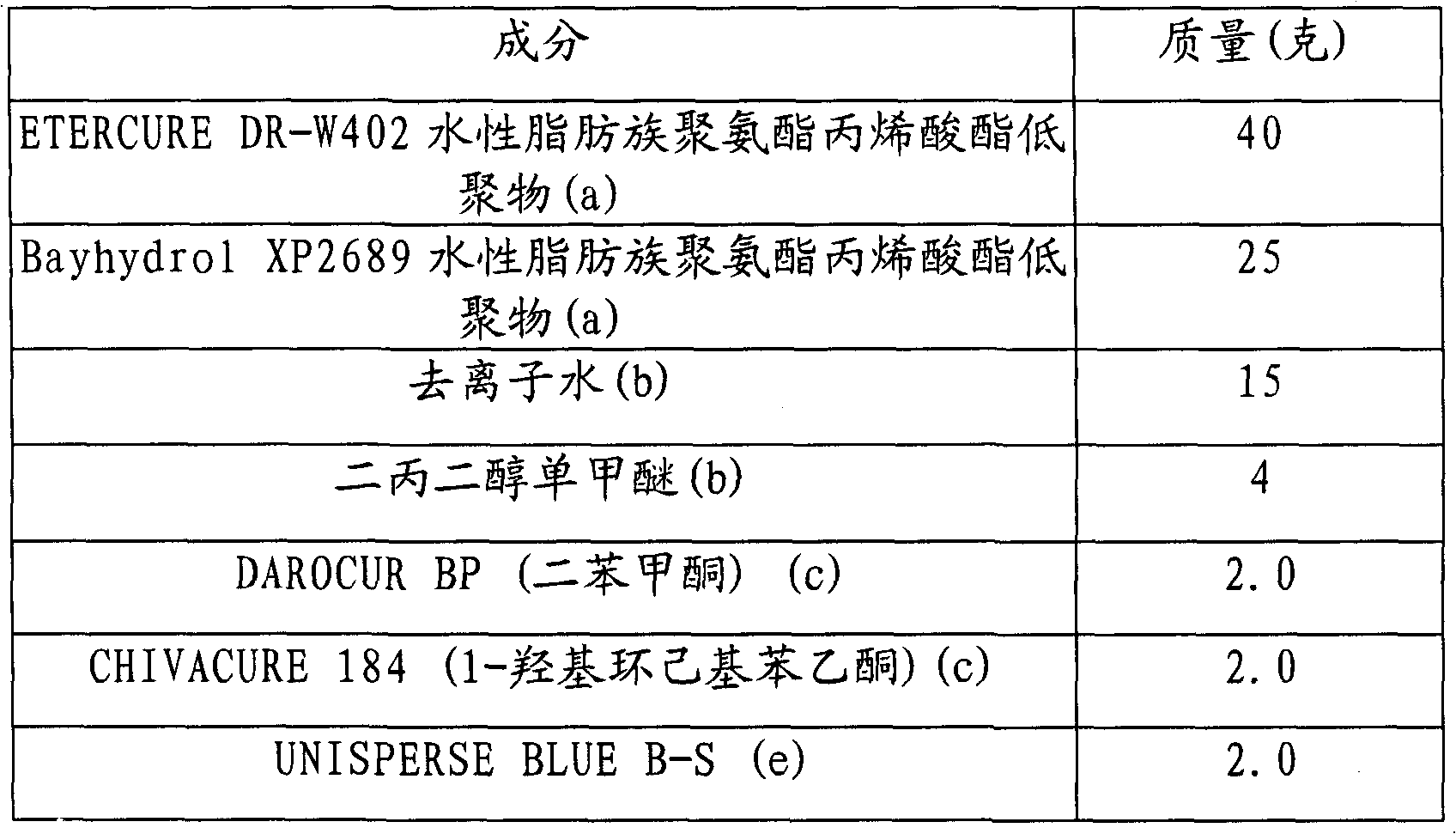

[0092] table 3

[0093]

[0094]

[0095] Add the diluent (deionized water / ethanol = 1 / 1 (volume ratio)) to the Iwata cup of the composition obtained above for about 10 seconds, spray it on the plastic substrate with an air spray gun, and then carry out 5 minutes in an oven at 60°C. ~10 minutes of pre-bake, then, through the medium pressure mercury lamp (800mJ / cm 2 ) for exposure. Then, the substrate with the coating film after exposure is subjected to a physical property test.

[0096] The results of the physical property test are as follows:

[0097] Film thickness: 10~15μm

[0098] Adhesion between coating film and substrate: 100 / 100

[0099] Coating film hardness: ≥H

[0100] Coating film gloss: 90

[0101] Chemical resistance of the coating film: pass (no scratches on the appearance, no peeling off)

[0102] Coating film heat resistance: pass

[0103] Appearance: flat, with red full light effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com