A method and device for co-producing hydrogen and electricity from organic waste

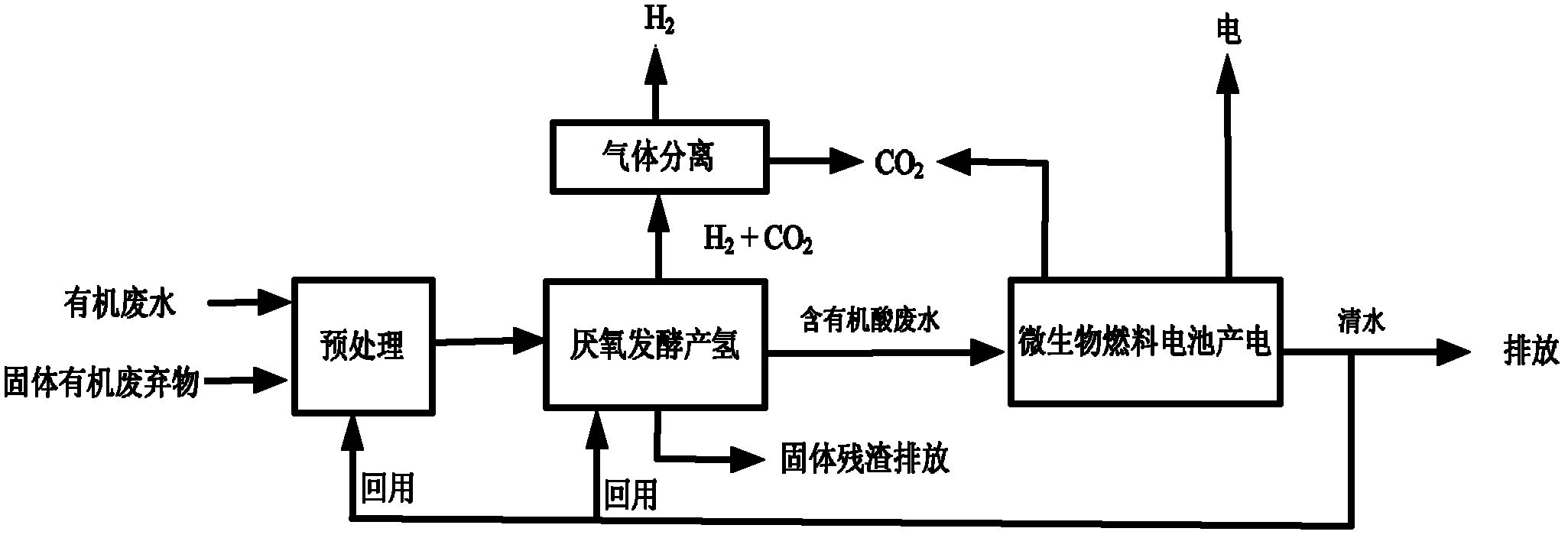

An organic waste, hydrogen technology, applied in biochemical equipment and methods, waste fuel, fuel cells, etc., can solve the problems of hydrogen production, power generation cannot be carried out at the same time, secondary pollution, unable to fully recover energy, etc., to expand raw materials The effect of utilization range, improving energy recovery rate, improving organic matter utilization rate and energy recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

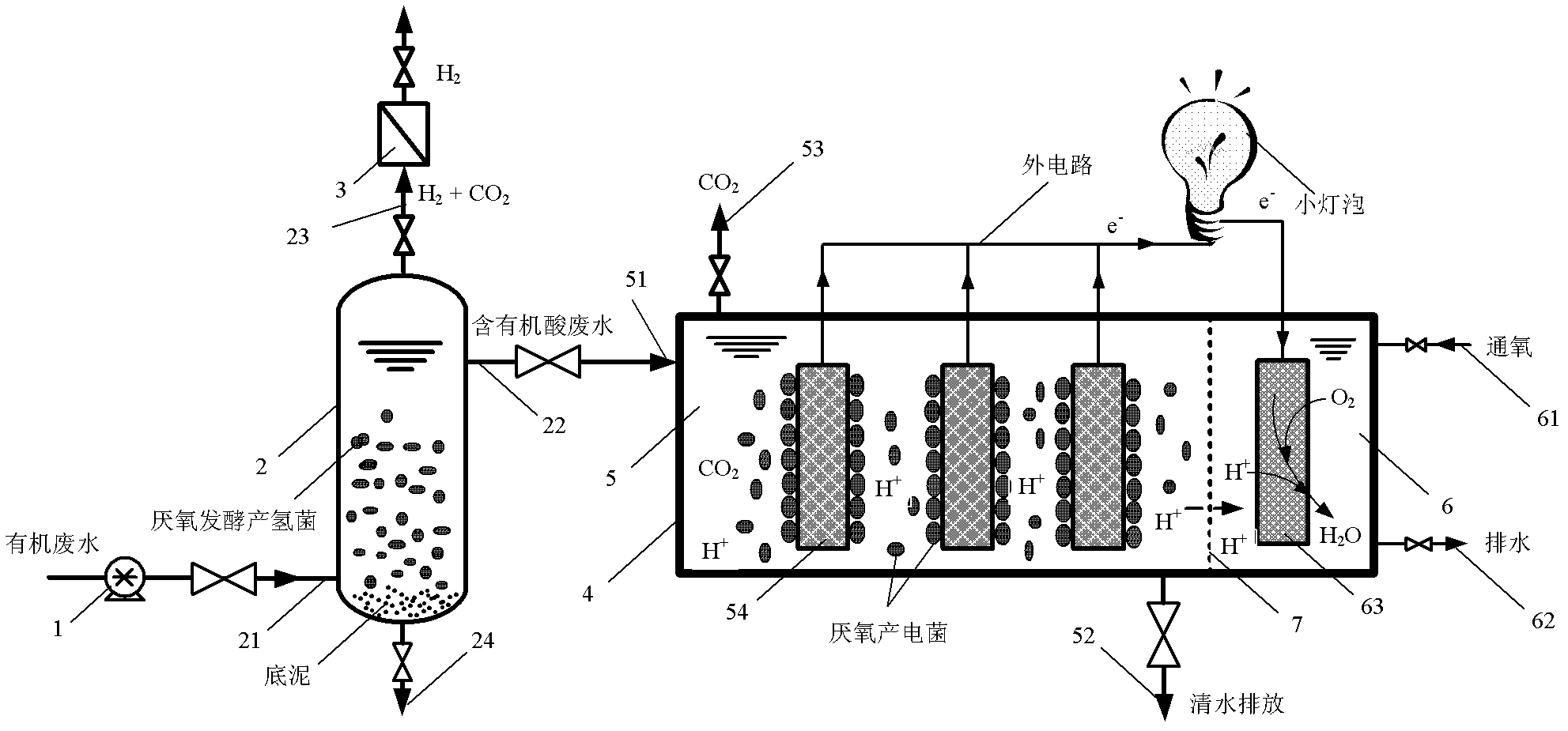

[0028] The implementation device of the present invention using organic wastewater as raw material is such as figure 2 As shown, the system composition includes: a feed pump 1, an upflow anaerobic reactor 2 and a microbial fuel cell 4 connected in sequence. The upflow anaerobic reactor is provided with a water inlet 21, a water outlet 22, and an air outlet 23 The air outlet 23 of the upflow anaerobic reactor is connected to the gas separator 3 and the mud discharge port 24, and the water outlet 22 of the upflow anaerobic reactor is in communication with the water inlet 51 of the anode chamber. The microbial fuel cell 4 is a conventional microbial fuel cell in the prior art, preferably an air cathode microbial fuel cell. The microbial fuel cell 4 is divided into an anode chamber 5 and a cathode chamber 6 by a proton exchange membrane 7. The anode chamber 5 and the cathode chamber 6 are respectively provided with an anode electrode 54 and a cathode electrode 63, the anode electro...

Embodiment 2

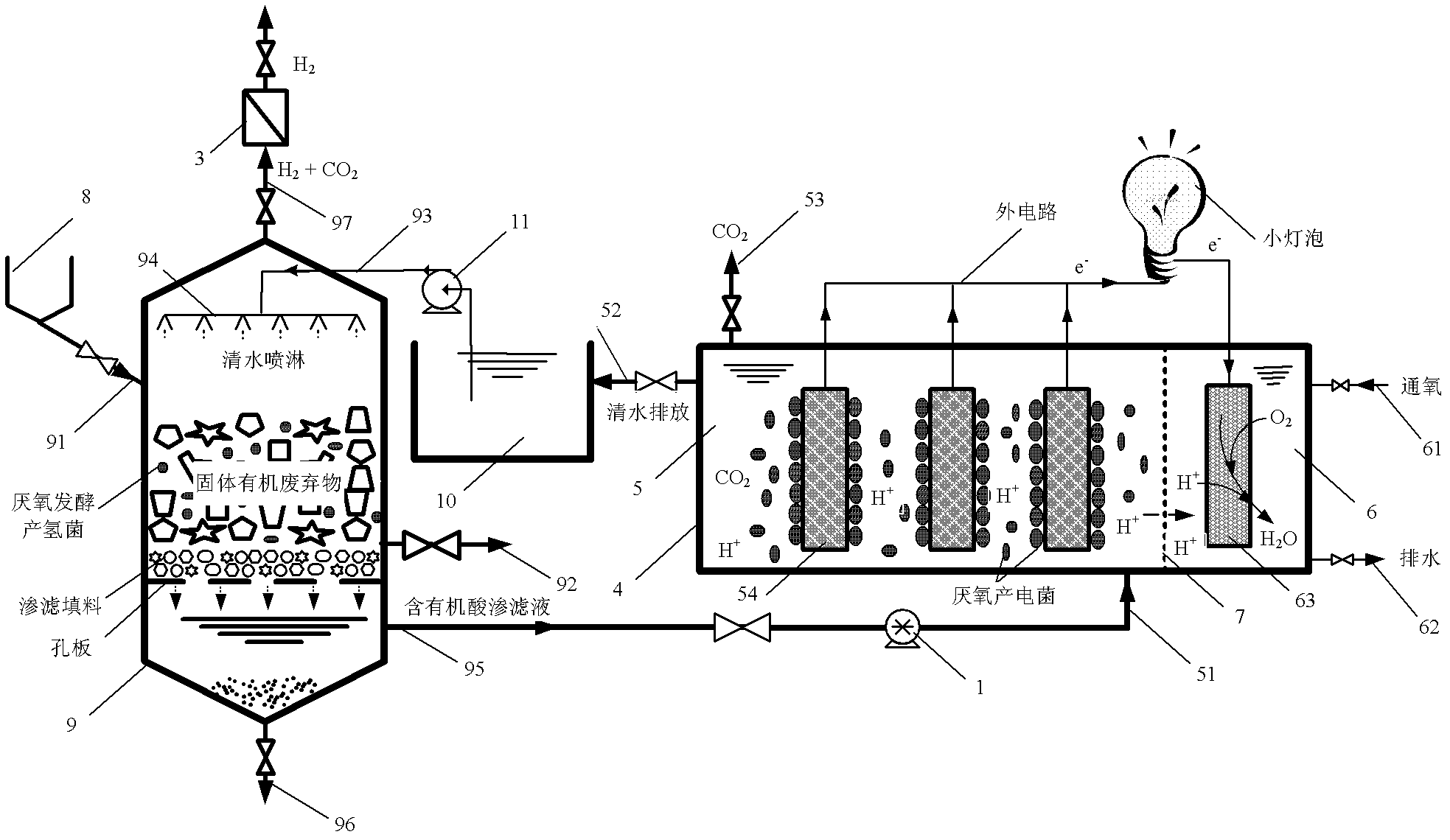

[0034] The implementation device of the present invention using solid organic waste as raw material is such as image 3 As shown, the system configuration includes: a feed hopper 8, a solid percolation bed anaerobic reactor 9, and a microbial fuel cell 4 connected in sequence. The solid percolation bed anaerobic reactor is provided with a feed port 91 and a feed port 92 , The water inlet 93, the top water distributor 94, the water outlet 95, the mud discharge port 96 and the air outlet 97, wherein the top water distributor 94 communicates with the booster pump 11 and the reservoir 10 through the water inlet 93. The bottom of the solid percolation bed anaerobic reactor is provided with percolation packing, the gas outlet 97 is connected to the gas separator 3, and the water outlet 95 is communicated with the water inlet 51 of the anode chamber of the microbial fuel cell 4. The microbial fuel cell 4 is a conventional microbial fuel cell in the prior art, preferably an air cathode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com