Fixture for forming U-shaped clip of steel plate spring

A leaf spring, U-shaped technology is applied in the field of tooling for forming U-shaped clips of automobile leaf springs, which can solve the problems of unstable positioning, cumbersome positioning adjustment, large accumulation and loss of waste products, etc., to achieve high forming size accuracy and reduce waste products loss. , the effect of reducing the generation of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

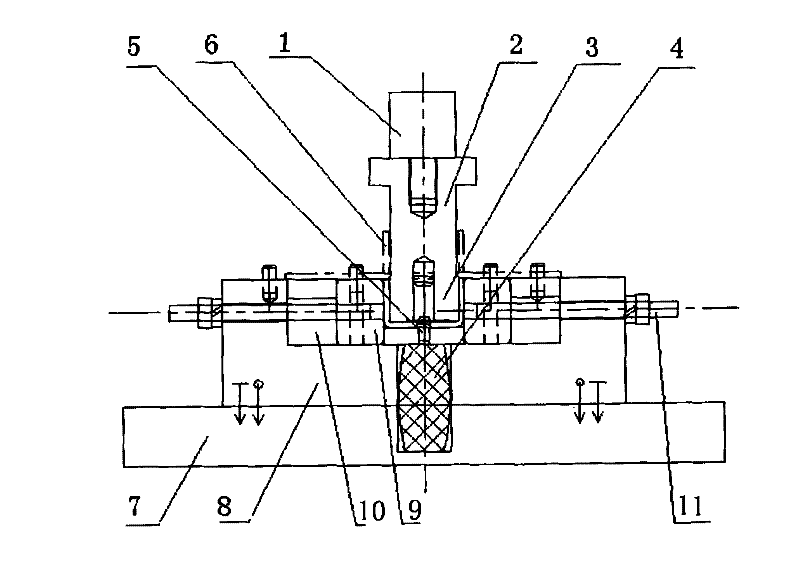

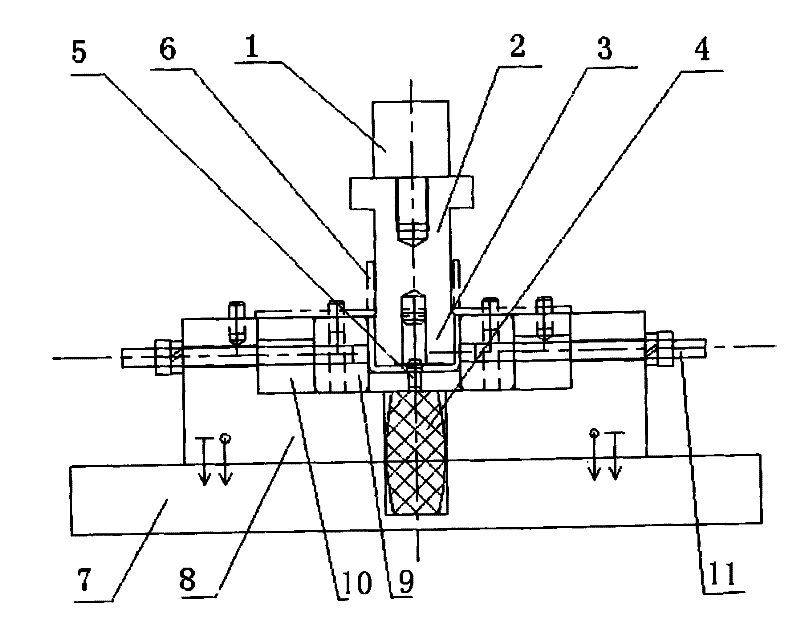

[0009] Such as figure 1 As shown, the present invention is respectively connected with the mold handle 1 and the upper module 3 at the upper end and the lower end of the upper mold fixing block 2, and a lower mold fixing block 8 is provided on the upper end surface of the lower template 7, and the upper end both sides of the lower mold fixing block 8 are respectively A lower module 9 and a gap adjustment backing plate 10 are provided, and the lower module 9 and the gap adjustment backing plate 10 are laterally fixed on both sides of the upper end of the lower mold fixing block 8 by locking bolts 11, and the gap between the two lower modules 9 is the same as that of the upper Corresponding to the module 3, an elastic stripping body 4 with a positioning pin 5 is arranged in the middle of the lower mold fixing block 8, and the positioning pin 5 corresponds to the center hole of the upper module 3. Through the above settings, when the present invention is working, the upper module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com