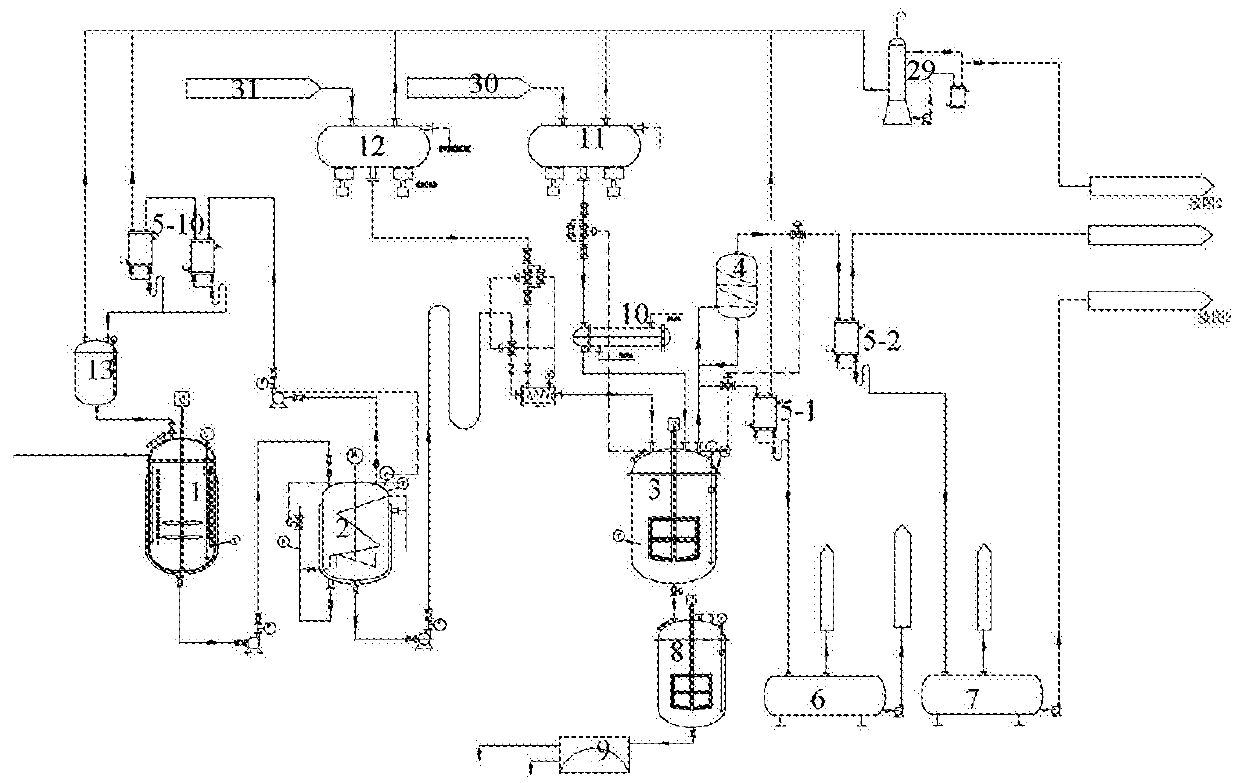

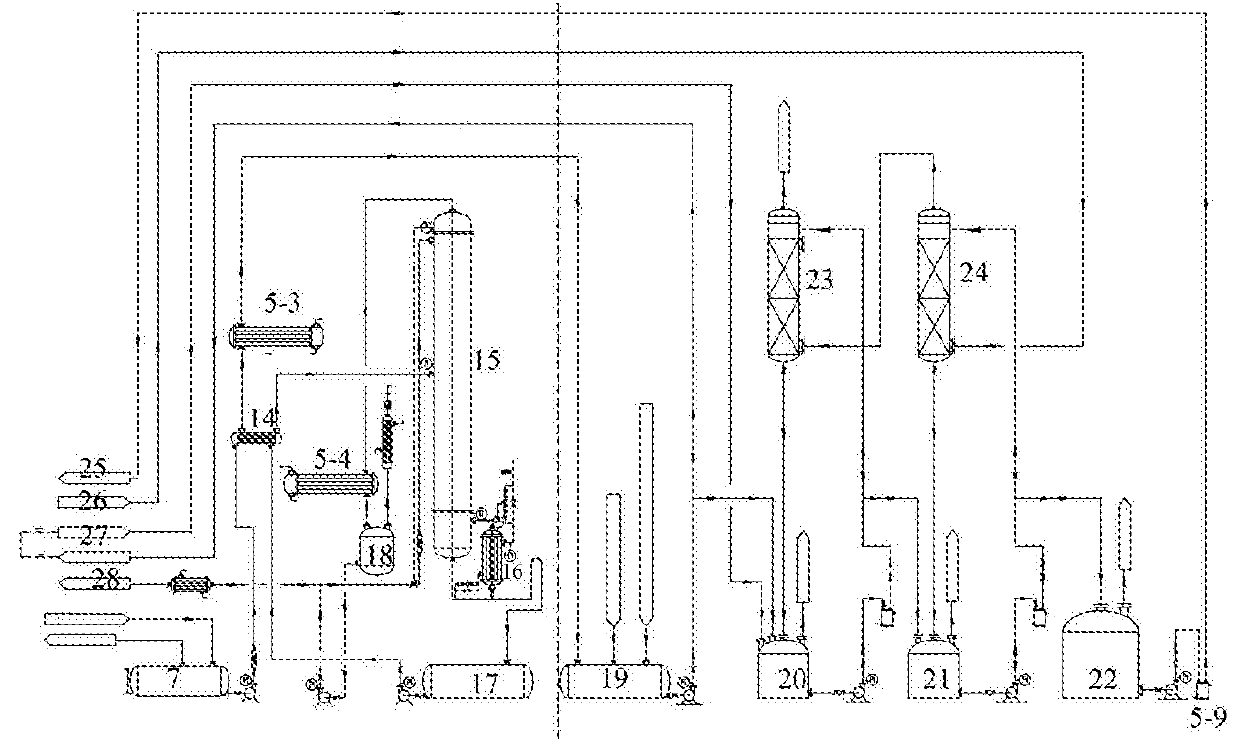

Acidolysis and solvent recycling process and device for producing glyphosate by using glycine method

A solvent recovery device and glyphosate technology are applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. The large amount of waste liquid and other problems can achieve the effect of large energy saving, reduction of methanol unit consumption, and improvement of comprehensive benefits.

Active Publication Date: 2017-05-24

HUBEI TAISHENG CHEM

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The introduction of a large amount of water has caused a series of problems such as large amount of process waste liquid such as mother liquor and methanol waste water, waste liquid entrainment and loss of dissolved materials, high pressure on environmental protection, and high process energy consumption.

In addition, due to the large amount of water introduced, and the specific heat capacity and phase change enthalpy of water are high, the energy consumption is high in the processes of heating up, evaporating, cooling down, condensing, rectifying and separating, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an acidolysis and solvent recycling process for producing glyphosate by using a glycine method, and belongs to the technical field of glyphosate production processes and methods. The acidolysis and solvent recycling process comprises steps of pretreatment for removing methanol from a synthetic liquid, acid methanol acidolysis, hydrochloric acid acidolysis, solvent recycling and the like. Acid methanol is adopted to replace hydrochloric acid for acidolysis of the synthetic liquid, and a small amount of hydrochloric acid is additionally supplied to stabilize the high-temperature acidolysis process in a later acidolysis period; in the acidolysis process, methylal is separated from a methylal and methanol solution through rectification, a small amount of methanol is replenished into the residual methanol solution which is cooled so as to blend the content of the methanol, the solution can be directly used for absorbing a hydrogen chloride gas, acid methanol can be generated after set contents of hydrogen chloride and methanol are met, and the acid methanol canbe fed back to the acidolysis process for reuse. Compared with a conventional glyphosate acidolysis and solvent recycling technique with a glycine method, the acidolysis and solvent recycling process has the advantages that the methanol recycling wastewater can be reduced by 2.5 t / t or greater, the mother liquid amount can be reduced by 0.3 t / t or greater, the steam consumption can be reduced by 1.5 t / t or greater, the power can be saved by 80 KWh / t or greater, the content of chloromethane can be increased by 0.3 t / t, the yield of glyphosate is increased by 0.3% or greater, and the production cost of the glyphosate can be lowered by 15-20%.

Description

A process and device for acidolysis and solvent recovery of glyphosate produced by glycine method technical field The invention relates to a new process of acidolysis (hydrolysis) process and solvent recovery process in the production process of glyphosate by glycine method, and belongs to the technical field of glyphosate production process. Background technique Glyphosate is a systemic, efficient, low-toxic, broad-spectrum, and destructive herbicide. It was first developed by Monsanto in the United States. It has been produced and used for more than 40 years. It is currently the largest pesticide in the world. . my country is one of the major producers of glyphosate. In 2015, the production capacity of the glyphosate industry was about 700,000 tons, and the actual output was about 460,000 tons. Both the production capacity and output rank first in the world. There are two production routes of glyphosate: glycine-alkyl ester method (referred to as glycine method) and imi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07F9/38

CPCC07F9/3813

Inventor 胡波黄明华

Owner HUBEI TAISHENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com