A hydrolysis device for producing glyphosate by glycine method

A hydrolysis device and glyphosate technology are applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, preparation of halogenated hydrocarbons, etc. The problem of large amount of waste liquid in the process can achieve the effect of large energy saving, reduction of methanol unit consumption, and improvement of comprehensive benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

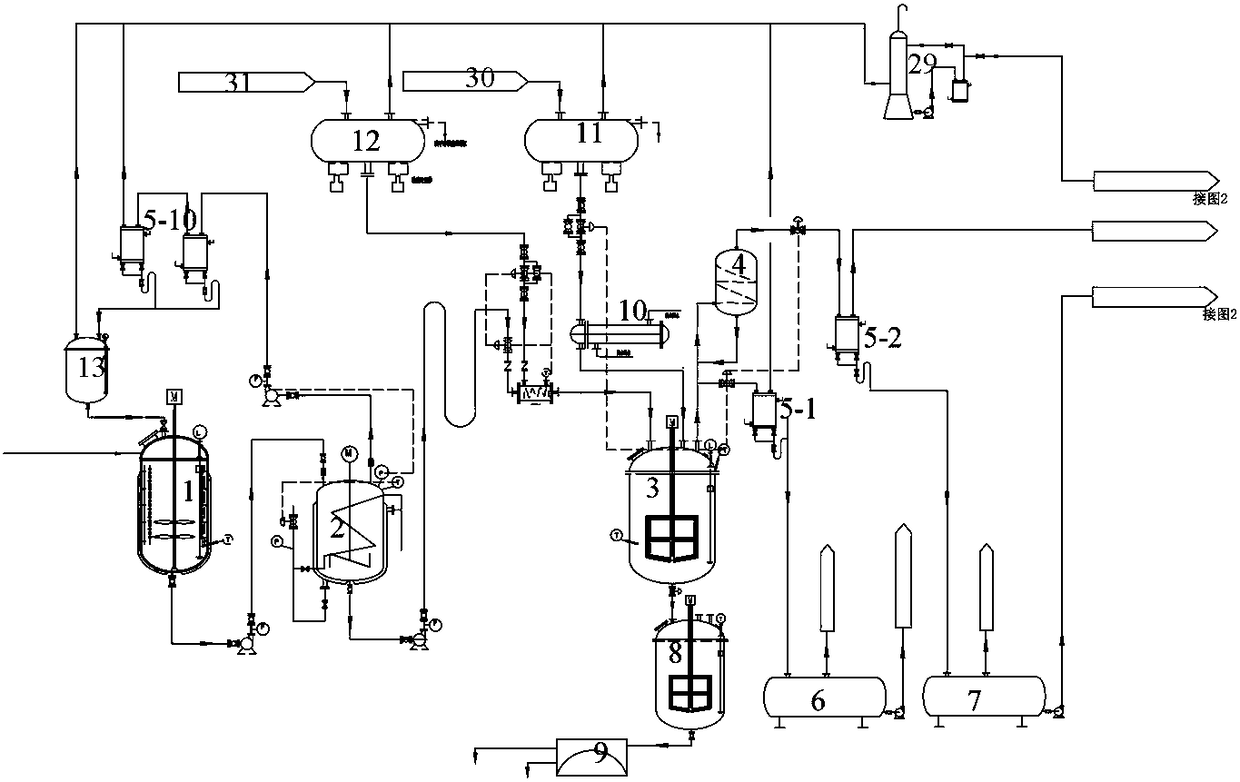

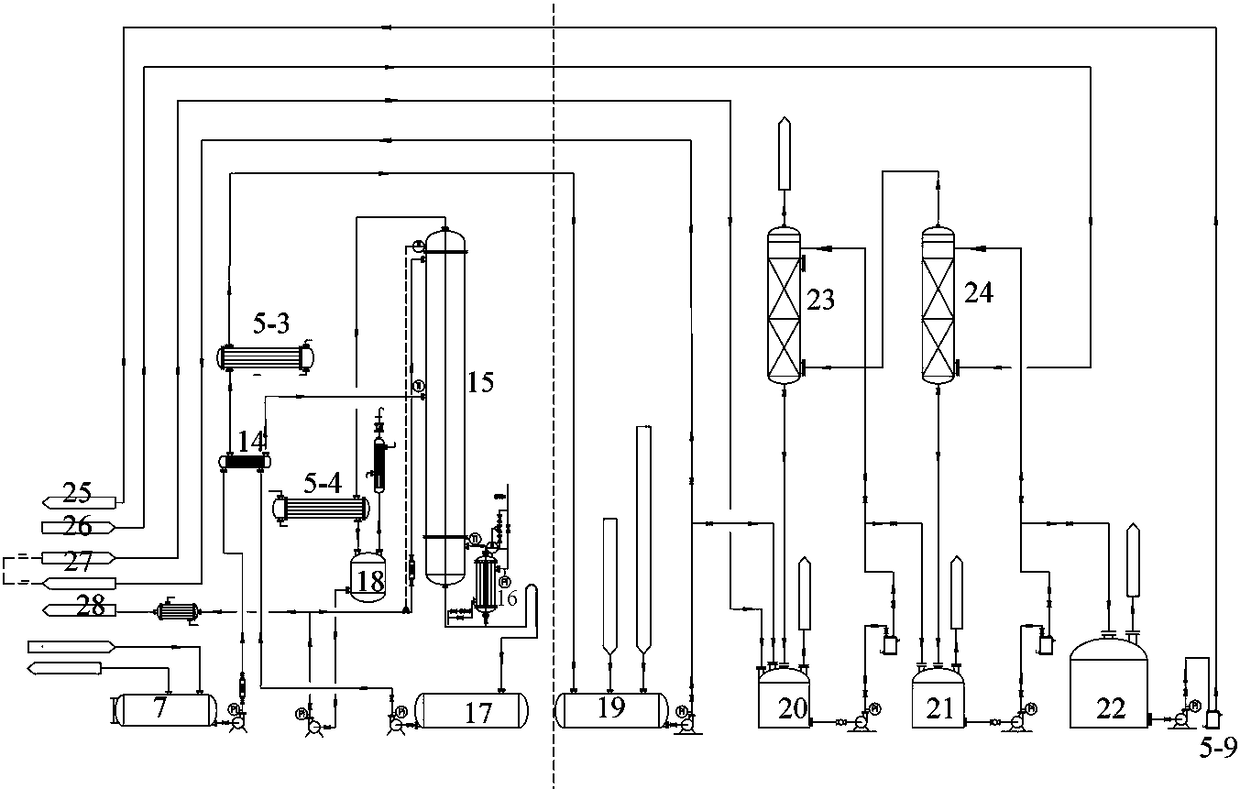

[0070] See attached page for hydrolysis process flow chart and solvent recovery process flow chart.

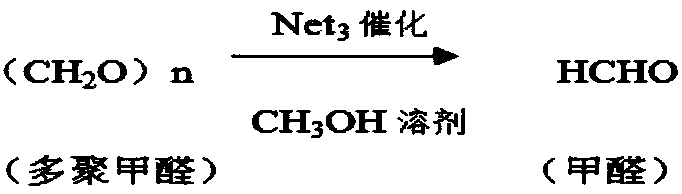

[0071]The present invention uses acid methanol (that is, methanol solution of hydrogen chloride) to replace hydrochloric acid (that is, aqueous solution of hydrogen chloride) and synthetic solution in the traditional process to carry out hydrolysis reaction. At the same time, the solvent recovery process is also improved. The methanol and methylal aqueous solution produced in the hydrolysis process are rectified to separate the methylal. The remaining methanol aqueous solution is cooled and added with a small amount of methanol to adjust the content, and then directly used to absorb hydrogen chloride gas. Hydrogen chloride and methanol reach the predetermined content to obtain acid methanol, which is reused in the hydrolysis process; only a small amount of methanol aqueous solution is distilled through the methanol tower to produce refined methanol to balance the total amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com