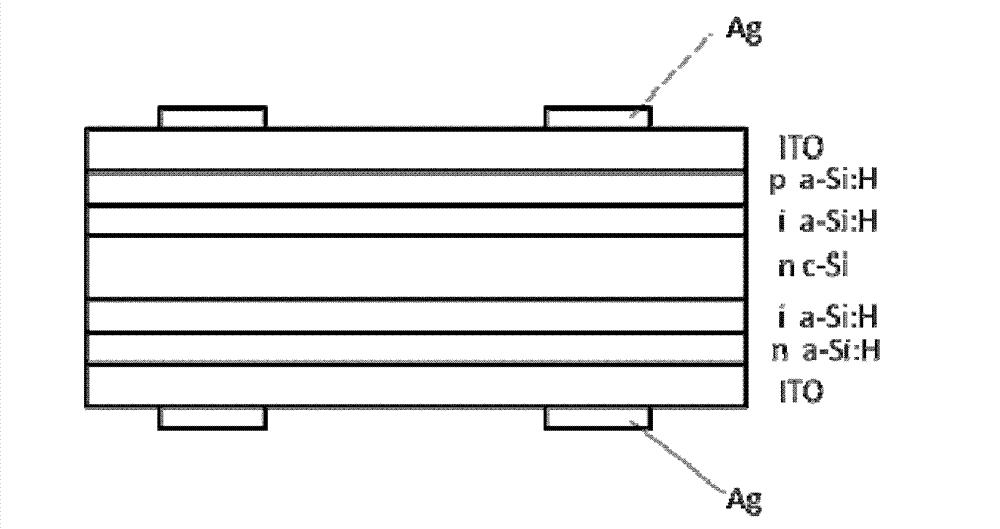

Serial-type equipment for manufacture of double-faced heterojunction solar cell in plasma enhanced chemical vapor deposition (PECVD) method and process

A solar cell and heterojunction technology, applied in the field of solar cells, can solve the problems of affecting cell performance, increasing equipment investment, being easily oxidized or adsorbed, etc., and achieving the effects of reducing production costs, simplifying manufacturing processes, and simplifying production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

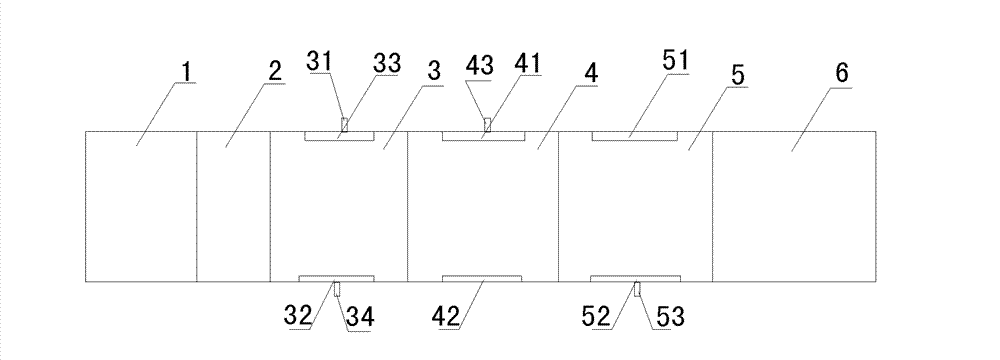

[0020] The tandem equipment for preparing double-sided heterojunction solar cells by the PECVD method of the present invention includes a deposition chamber, a gas path control system, an electric control system and a vacuum unit, and the deposition chamber is connected with the gas path control system, the electric control system and the vacuum unit respectively. The vacuum unit is connected, and the electric control system is connected with the gas circuit control system. The above-mentioned gas path control system, electric control system and vacuum unit are all prior art.

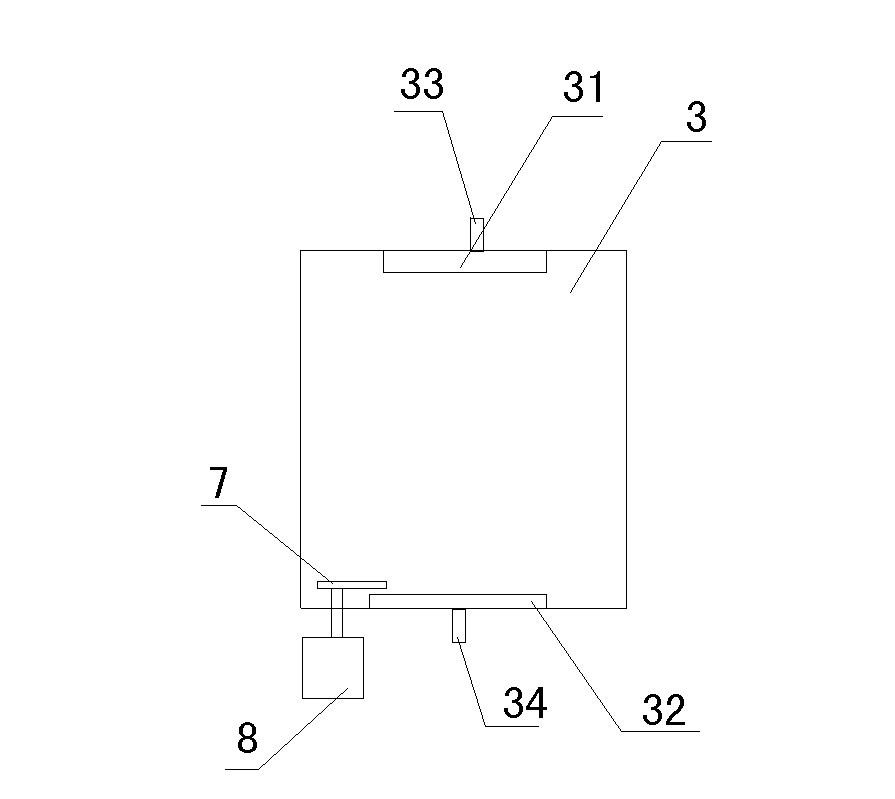

[0021] The basic structure of the deposition chamber in the present invention is as figure 2 As shown, it includes a film feeding chamber 1 , a preheating chamber 2 , an intrinsic layer deposition chamber 3 , a p-type deposition chamber 4 , an n-type deposition chamber 5 and a film output chamber 6 arranged in series. An upper electrode 31 and a lower electrode 32 are provided in the intrinsic layer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com