Method for expressing relationship of process manufacturing procedures

A method of expression, manufacturing technology, applied in general control systems, control/regulation systems, computer control, etc., and can solve problems such as poor scalability, limited freedom and flexibility of operations, and insufficient flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

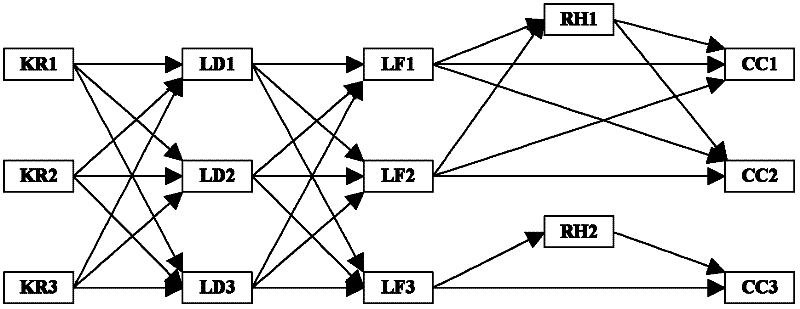

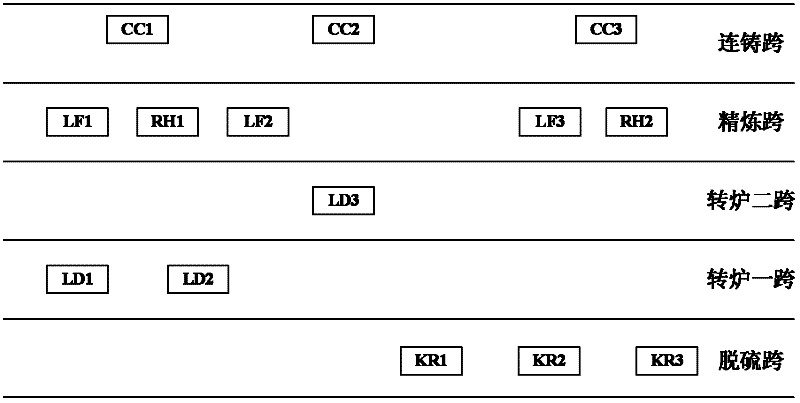

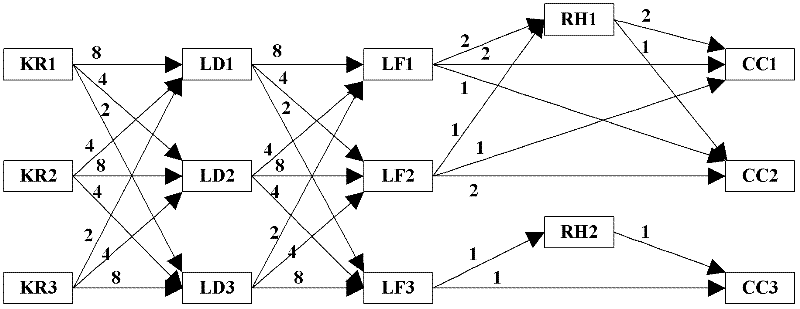

[0075] The present invention provides a method for expressing process relationship in the process manufacturing industry. This method designs a series of matrices or vectors to model the process relationship, specifically including the following matrices or vectors: process name vector, process equipment number vector, and products in batches Numerical vector, accessibility matrix between each process equipment, transportation time matrix between processes, multi-process route matrix, accessibility weight matrix between each process equipment, processing start time and end time matrix of each product, and each The processing equipment allocation matrix of the product in each process.

[0076] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

[0077] Taking the steelmaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com