Method for purifying organic waste gas containing epoxypropane or ethylene oxide

A technology of ethylene oxide and propylene oxide, which is applied in the field of organic waste gas purification and treatment, can solve the problems of many impurities, the inability to effectively use solid acid catalyst for catalytic treatment for a long time, and the ineffective use of raw materials such as propylene oxide or ethylene oxide. , to achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

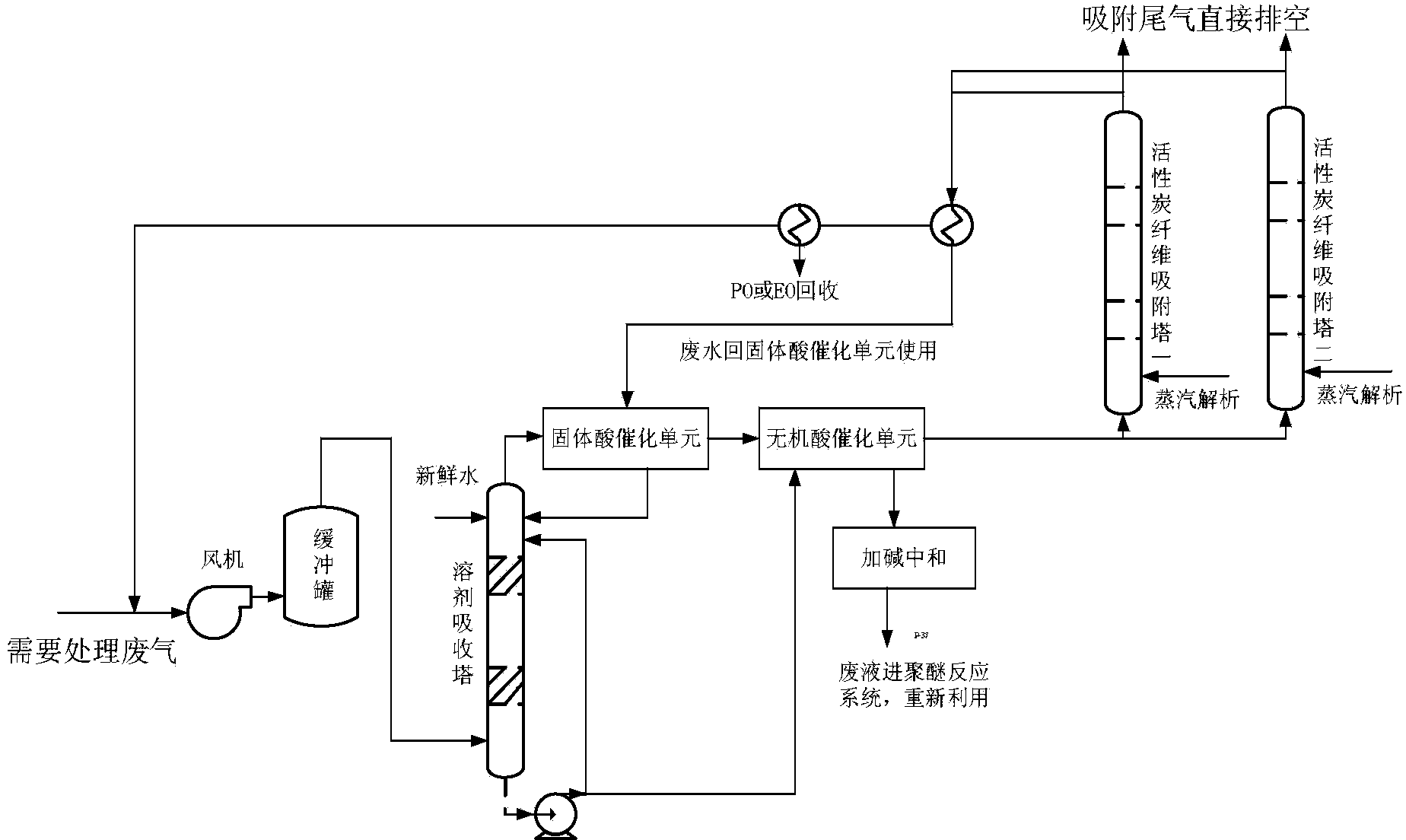

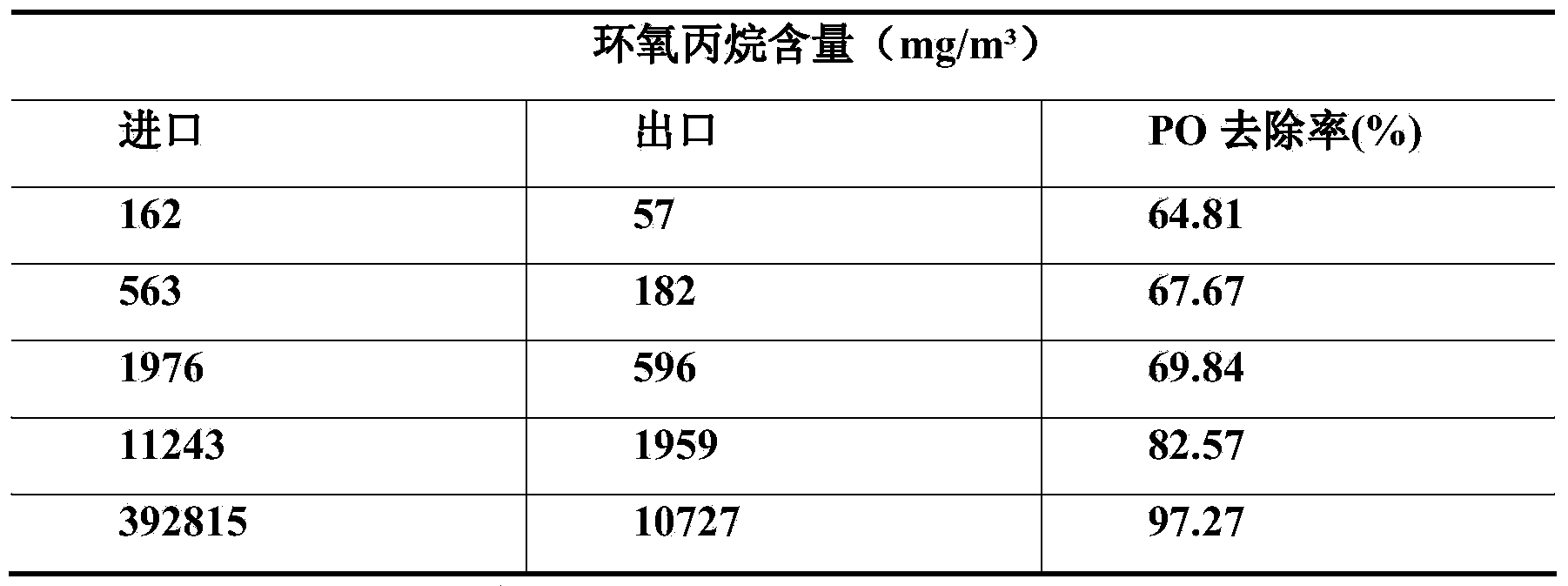

[0053] The waste gas in this embodiment comes from: the process of generating polyether polyol by polymerization reaction of initiator propylene glycol, sorbitol, sugar, etc. and propylene oxide under the action of strong basic catalyst, the waste gas treatment process is as follows figure 1 As shown, the exhaust gas treatment steps are as follows:

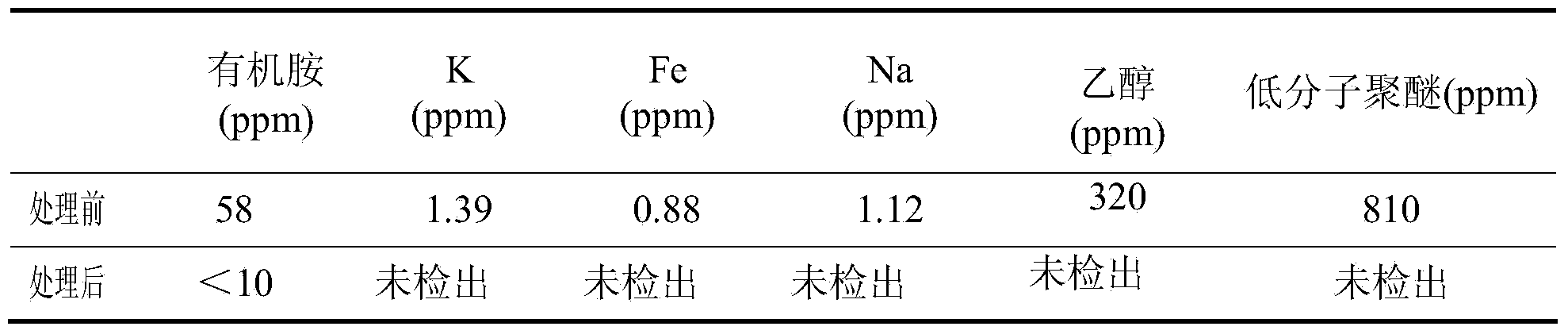

[0054] (A) The exhaust gas enters the buffer tank through the fan for buffering, so that the maximum flow rate and the highest concentration part of the exhaust gas are homogenized, and the average gas volume is kept at 3000Nm 3 / day, PO concentration is about 30v%; other components in the waste gas include: organic amine 58ppm, ethanol 320ppm, low molecular weight polyether 810ppm, metal ions K, Fe, Na, and the rest is nitrogen. The specific content is shown in Table 2.

[0055] (B) The homogenized exhaust gas enters the solvent absorption tower filled with modified activated carbon fillers, the residence time of the exhaust gas...

Embodiment 2

[0069] The exhaust gas in this embodiment comes from the process of generating polyether polyols by the polymerization reaction of initiators such as ethylene glycol, sorbitol, sugar, etc., with ethylene oxide under the action of a strong basic catalyst, and the exhaust gas treatment steps are as follows:

[0070] (A) The organic waste gas is buffered by the buffer tank to homogenize the maximum flow rate and the highest concentration part of the waste gas, and keep the average gas volume at 3000Nm 3 / day, the EO concentration is about 35v%; other impurity components in the waste gas include: organic amine 83ppm, ethanol 240ppm, low molecular weight polyether 634ppm, metal ions K, Fe, Na, and the rest is nitrogen, the specific content is shown in Table 4;

[0071] (B) After homogenization, it enters the solvent absorption tower filled with modified activated carbon filler, the residence time of the waste gas in the tower is 10s, and the solvent circulation in the tower is 20Nm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com