Exploitation technique for disgorging thick oil by pouring air to assistant steam

A technology for injecting steam and steam, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of large heat loss of steam, poor fluidity of crude oil in production wells, and reduce the viscosity of crude oil, so as to reduce the comprehensive economic cost, increase crude oil mobility, and maintain formation temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

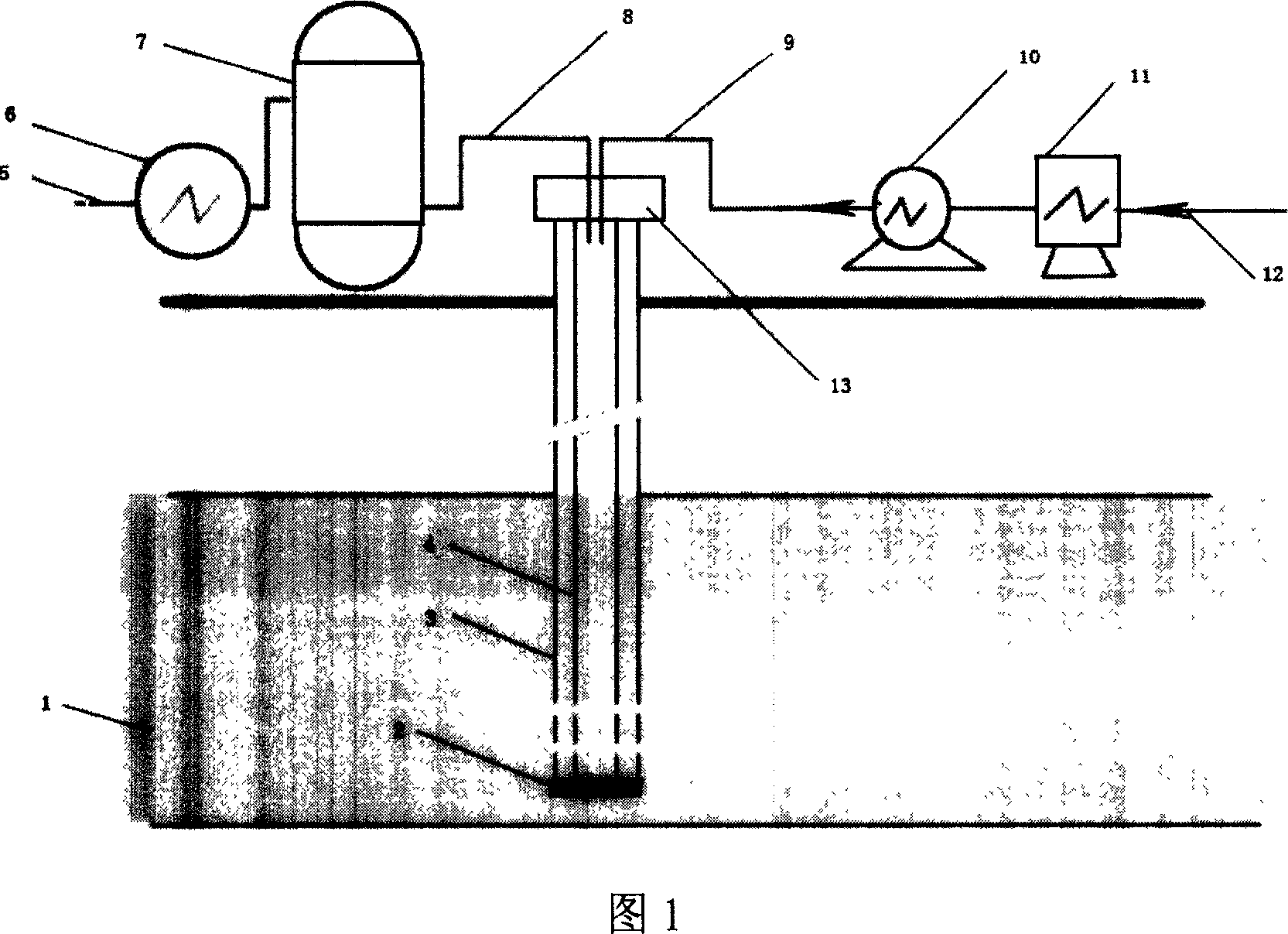

[0014] 1. Heavy oil layer 2. Artificial well bottom 3. Casing 4. Oil pipe 5. Intake pipeline 6. Air compressor 7. Air pressure stabilization device 8. High pressure gas injection pipeline 9. High pressure steam injection pipeline 10. Steam pressure stabilization device 11. Heating boiler 12. Water inlet pipe

[0015] As shown in Fig. 1, after the well is drilled, casing sand control completion is performed on the heavy oil layer 1 to prevent sand production in the later stage of production. During the well completion process, an artificial well bottom 2 is built to withstand the high pressure during steam injection and high-pressure air. The ground steam injection system consists of a heating boiler 10 , a steam pressure stabilizing device 10 and a high pressure steam injection pipeline 9 . The air injection system consists of an air compressor 6 , an air pressure stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com