Three-level fermentation of lysine and coating products thereof

A lysine and product technology, applied in the field of amino acid fermentation, can solve the problems of increasing the workload of animal feeding, affecting the efficiency of animal absorption and utilization, etc., and achieves the effects of no potential safety hazards, simplified operation, and reduced release speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

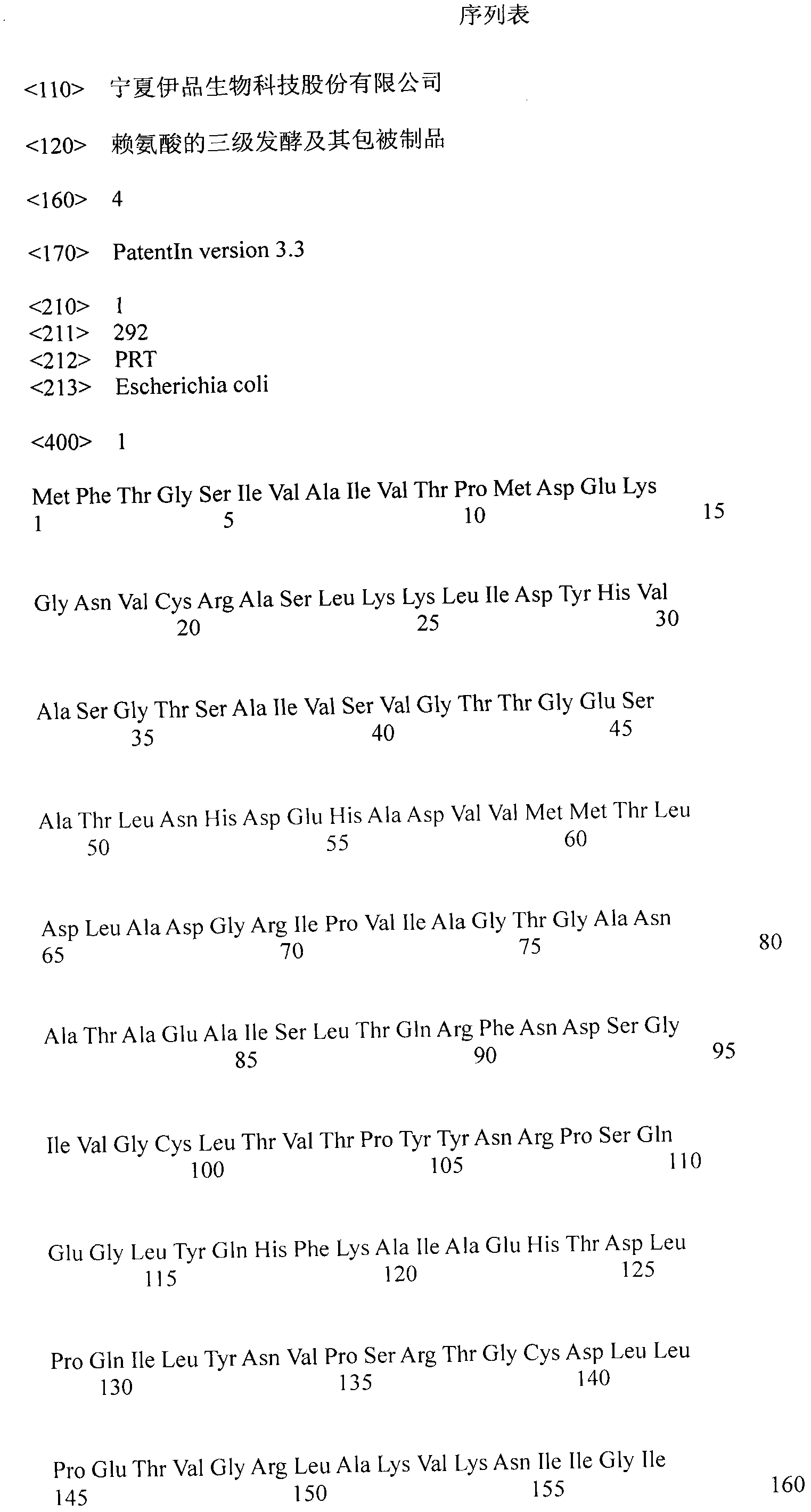

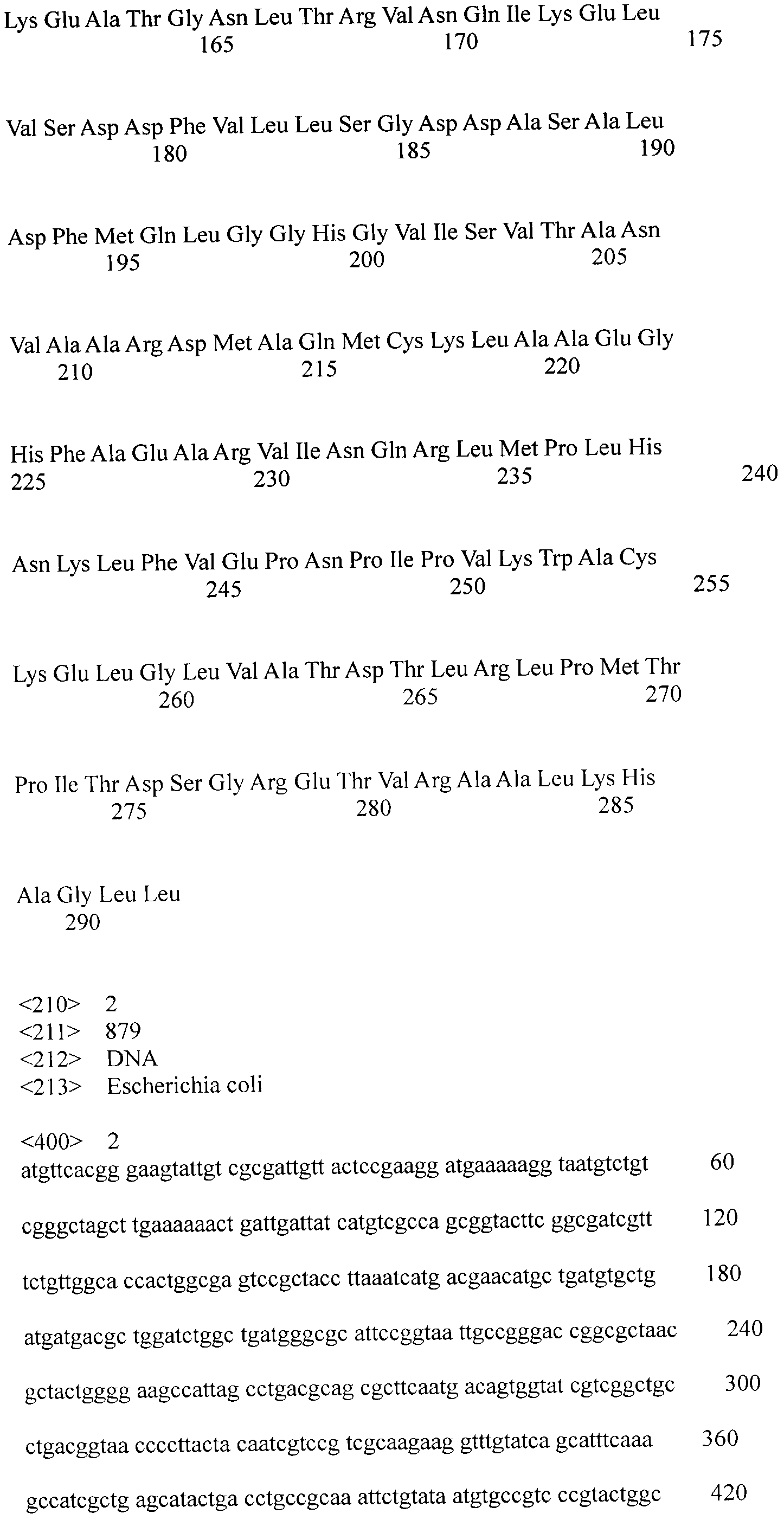

[0034] Embodiment 1 Preparation of dihydrodipicolinate synthase variant gene

[0035] According to the sequence we designed, we commissioned Shanghai Sangon Biotechnology Co., Ltd. to synthesize the variant gene encoding dihydrodipicolinate synthase through commercial channels and constructed it into the Escherichia coli-Corynebacterium shuttle plasmid pMS2 (available from the American Type Microorganisms Collection (ATCC), item number ATCC 67189). The cloning process was carried out according to the "Molecular Cloning Experiment Guide" and the operation guide of the commercial reagents used. The brief process is as follows:

[0036] Synthesize nucleic acid fragments of dihydrodipicolinate synthase variant genes by an automatic DNA synthesizer, phosphorylate the 5' ends of these nucleic acid fragments with T4 polynucleotide kinase (purchased from TaKaRa Company), and then equimolar ratio The five nucleic acid fragments were mixed and denatured at 65°C for 5 minutes, annealed ...

Embodiment 2

[0038] The fermentation experiment of embodiment 2 coryneform bacteria

[0039] The pMS2-dap plasmid is transferred into L-lysine-fermenting coryneform bacteria engineering bacteria (available from the American Type Microorganism Collection (ATCC), product number ATCC 31269) by electroporation method, and its brief process is: the coryneform bacteria Shake culture in 50 mL LB liquid medium until OD500 reaches 0.7, collect the cells by centrifugation, wash with 0°C pre-cooled 10% (V / V) glycerol solution, and resuspend the cells in 200 μL pre-cooled 10% (V / V) glycerol solution. V) In glycerol solution, add pMS2-dap plasmid, mix well, transfer to 0.1cm electric shock cup, conduct electric shock at 1.8kV for 5ms, then immediately add 1mL liquid LB containing 0.5% (M / M) glucose for culture Incubate at 42°C for 5 minutes, spread on solid LB medium containing 100 μg / mL ampicillin and 35 μg / mL kanamycin, and culture at 30°C for 36 hours. After the total DNA was extracted from the tra...

Embodiment 3

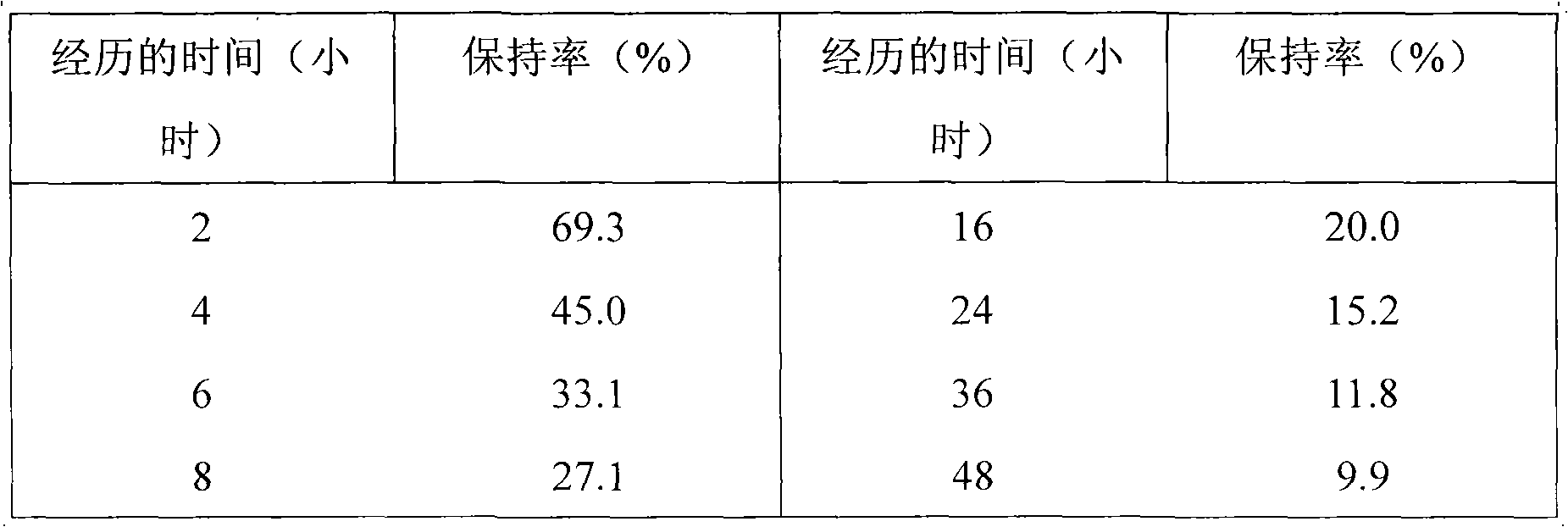

[0041] The tertiary fermentation example of embodiment 3L-lysine

[0042] First-level preparation: the coryneform bacterium engineered bacterium that the transformation of embodiment 2 has pMS2-dap plasmid inserts 20 cubic meters of fermentors with 0.5% inoculum (the medium formula wherein is: 600 kilograms of glucose, 200 kilograms of sugarcane molasses , corn steep liquor 520 kg, KH 2 PO 4 45 kg, MgSO 4 ·7H 2 O 7 kg, FeSO 4 ·7H 2 O 0.5 kg, MnSO 4 ·7H 2 O 0.5 kg, 12 grams of biotin, and 5 grams of folic acid, the volume was adjusted to 18 cubic meters with water), and cultured at 31° C. with saturated aeration for 10 hours to increase the cell density. During the period, the amount of viable bacteria accumulated with glucose was significantly better than that with sucrose.

[0043] Second-level preparation: the nutrient solution of 20 cubic meters of fermentors is injected into 50 cubic meters of fermentors (wherein the formula of the medium is the same as above) wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com