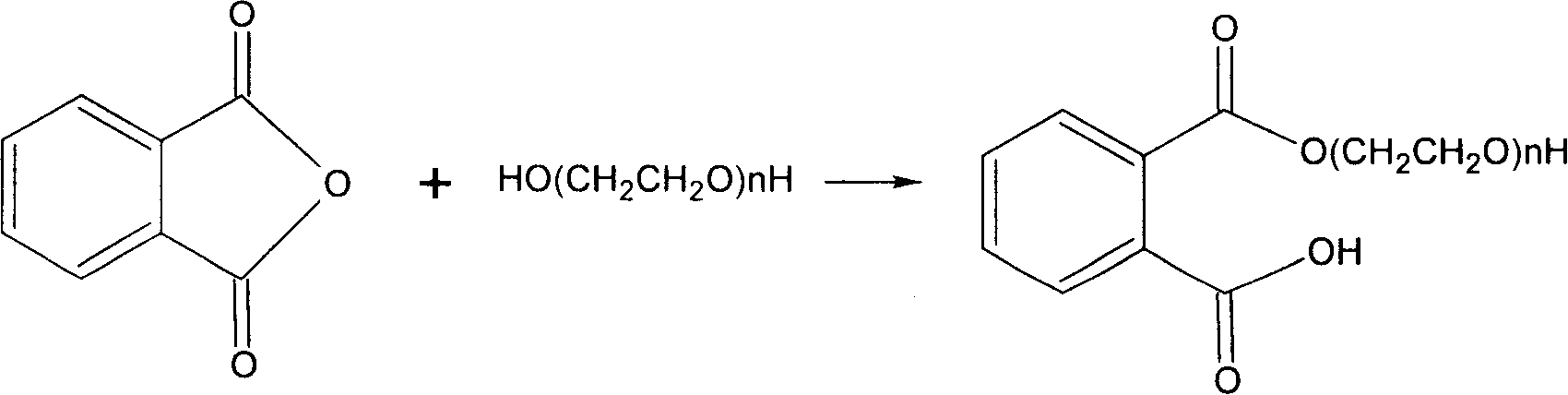

Method of preparing nonionic surfactant o-benzenedicarboxylic acid polyethylene glycol ester

A technology of phthalic acid and polyethylene glycol ester, which is applied in the field of preparation of nonionic surfactants, can solve the problems of high process reaction temperature, small application range, and high equipment requirements, and achieve wide application, improved solubility, and activity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Get 100 grams of phthalic anhydride and 364.6 grams of polyethylene glycol (PEG-600) (the molar ratio is 1:0.9) and join in a 1000 ml three-necked flask, after mixing evenly, add 0.5 grams of phosphorous acid catalyst, heat up To 75 DEG C and keep for 5 hours, the material is colorless and transparent, then add 30% potassium hydroxide to neutralize to pH value 3.5, promptly make about 465. grams of polyethylene glycol phthalate.

Embodiment 2

[0012] Get 100 grams of phthalic anhydride and 405.1 grams of polyethylene glycol (PEG-600) (molar ratio is 1:1) and join in a 1000 ml three-necked flask, after mixing evenly, add 1.5 grams of phosphorous acid catalyst, heat up To 85 ℃ and keep for 3 hours, the material is colorless and transparent, then add 30% sodium hydroxide to neutralize to pH value 1.5, promptly make about 508 grams of polyethylene glycol phthalate.

Embodiment 3

[0014] Take 100 grams of phthalic anhydride and 445.6 grams of polyethylene glycol (PEG-600) (the molar ratio is 1:1.1) and join in a 1000 ml three-necked flask, after mixing evenly, add 1.0 grams of 98% sulfuric acid catalyst, Raise the temperature to 78° C. and keep it for 3.5 hours, the material is colorless and transparent, then add 30% potassium hydroxide to neutralize to a pH value of 3.5, and obtain about 547. g of polyethylene glycol phthalate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com