Method for converting hydrazine hydrate in waste water

A technology for hydrazine hydrate and waste water, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc. It can solve the problems of pollution, large dosage of chemicals, and low efficiency at low temperature, and overcome the problems of bulky equipment, The prospect of wide application and promotion, the effect of simple follow-up treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

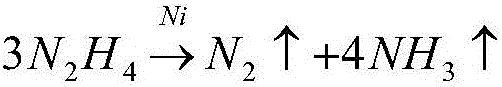

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 1300ml solution containing 0.1% hydrazine hydrate in 5L reactor, add 0.03g transition metal compound H 2 PtCl 6 ·6H 2 O, 0.04g of protective agent PVP powder, 1.6ml of 95% ethanol solvent, adjust the pH of the solution to 9 with ammonia water, control the reaction temperature at 10°C, stir at a rate of 80 rpm, and react for 24 hours.

[0023] In this embodiment, the content of hydrazine hydrate before the reaction was 0.1%, and the content of hydrazine hydrate after the reaction was 0.07%.

Embodiment 2

[0025] Add 1300ml solution containing 1% hydrazine hydrate in 5L reactor, add 0.12g transition metal compound RuCl 3 ·3H 2 O, 0.16g protective agent PVA powder, 6.4ml95% ethanol solvent, adjust the pH of the solution to 10 with ammonia water, control the reaction temperature at 20°C, stir at a rate of 80 rpm, and react for 24 hours.

[0026] In this embodiment, the content of hydrazine hydrate before the reaction was 1%, and the content of hydrazine hydrate after the reaction was 0.54%.

Embodiment 3

[0028] Add 1300ml solution containing 5% hydrazine hydrate in 5L reactor, add 0.6g transition metal compound FeCl 2 4H 2 O, 0.8g protective agent PVP powder, 32ml95% ethanol solvent, adjust the pH of the solution to 11 with NaOH, control the reaction temperature at 30°C, stir at a rate of 80 rpm, and react for 24 hours.

[0029] In this embodiment, the content of hydrazine hydrate before the reaction was 5%, and the content of hydrazine hydrate after the reaction was 1.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com