Method and combined solution for increasing productivity of low-porosity, low-permeability and low-pressure reservoir oil well

A low-permeability, combined fluid technology, applied in drilling compositions, chemical instruments and methods, earthwork drilling and mining, etc., can solve problems such as complex construction process, high operating cost, and short validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

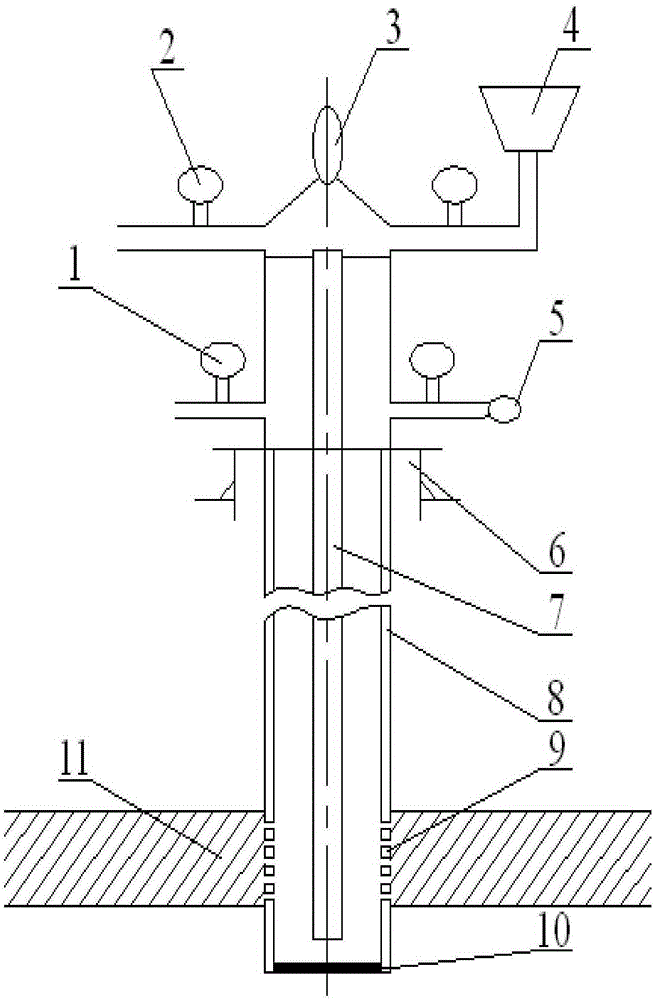

Image

Examples

Embodiment 1

[0073] Embodiment 1: the test of No. 1 oil well in Yanchang Oilfield

[0074] 1. Investigate the geological conditions and wellbore structure of No. 1 oil well

[0075] Investigate the wellbore structure when the present invention works, know that this oil well reservoir belongs to sandstone and siltstone; Low porosity and low permeability oil layer; The well depth is 1428.3m; the perforation range is 1324.2-1353.5m; the daily fluid production before the stimulation operation is 2.5t; the daily oil production is 2.0t.

[0076] 2. Prepare the combination liquid

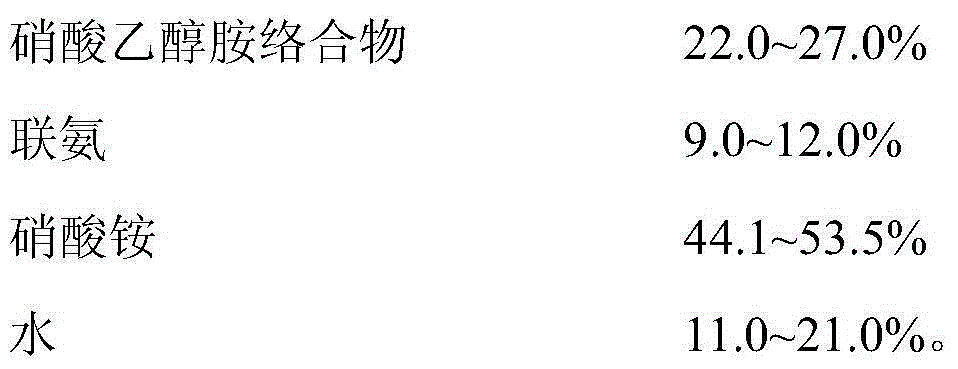

[0077] According to the inner diameter of the casing obtained in step 1 and the height from the bottom of the well to the target layer, the volume of the casing annulus is calculated. According to the volume of the casing annulus obtained, it can be known that the component A solution that can be prepared in this oil well is 650 kg, and its composition and The ratio is 47.0% ammonium nitrate NH 4 NO 3 , 22.0% etha...

Embodiment 2

[0090] Embodiment 2: No. 2 oil test in Yanchang Oilfield

[0091] 1. Investigate the geological conditions and wellbore structure of No. 2 oil well

[0092] Investigate the well structure during the operation of the present invention, and learn the geological conditions and well structure of No. 2 oil well: the reservoir belongs to sandstone and siltstone; medium-porous low-permeability oil layer; casing inner diameter The well depth is 1380.6m; the perforation range is 1282.0-1309.2m; the daily fluid production before the stimulation operation is 3.0t; the daily oil production is 2.5t.

[0093] 2. Prepare the combination liquid

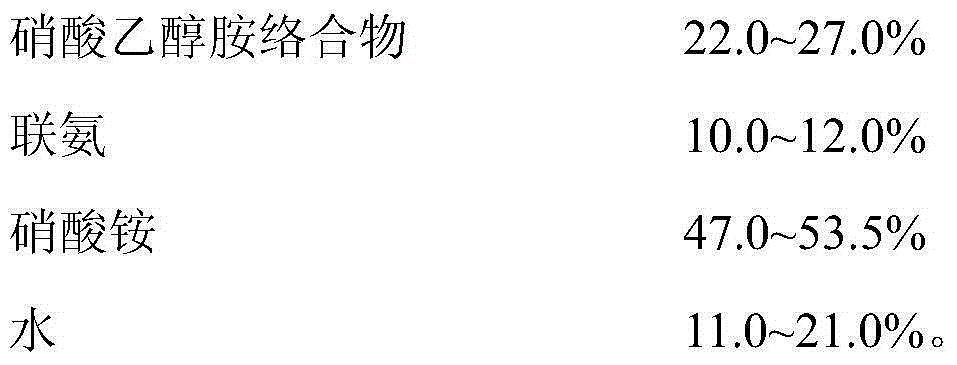

[0094] According to the inner diameter of the casing obtained in step 1 and the height from the bottom of the well to the target layer, the volume of the casing annulus is calculated. According to the obtained volume of the casing annulus, it can be known that the oil well needs to prepare 650 kg of component A solution, and its composition and pro...

Embodiment 3

[0107] Embodiment 3: the test of No. 3 oil well in Yanchang Oilfield

[0108] 1. Investigate the geological conditions and wellbore structure of No. 3 oil well

[0109] Investigate the well body structure when the present invention operates, the geological conditions and the well body structure of No. 3 oil wells: the reservoir belongs to sandstone and siltstone; low porosity and low permeability oil layer; casing inner diameter The well depth is 1217.6m; the perforation range is 1143.3-1174.0m; the well was an abandoned oil well before the stimulation operation, and the daily oil production was 0t.

[0110] 2. Prepare the combination liquid

[0111] According to the inner diameter of the casing obtained in step 1 and the height from the bottom of the well to the target layer, the volume of the casing annulus is calculated. According to the obtained volume of the casing annulus, it can be known that the oil well needs to prepare 650 kg of component A solution, and its compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com