Method for preparing uranium nitrate through catalytic hydrogenation reduction of uranyl nitrate

A technology for catalytic hydrogenation and uranyl nitrate, applied in chemical instruments and methods, uranium compounds, inorganic chemistry, etc., can solve problems such as difficulties in industrialization, reduction of conversion rate of hexavalent uranium, etc., to avoid side reactions, good economy, The effect of high gas conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

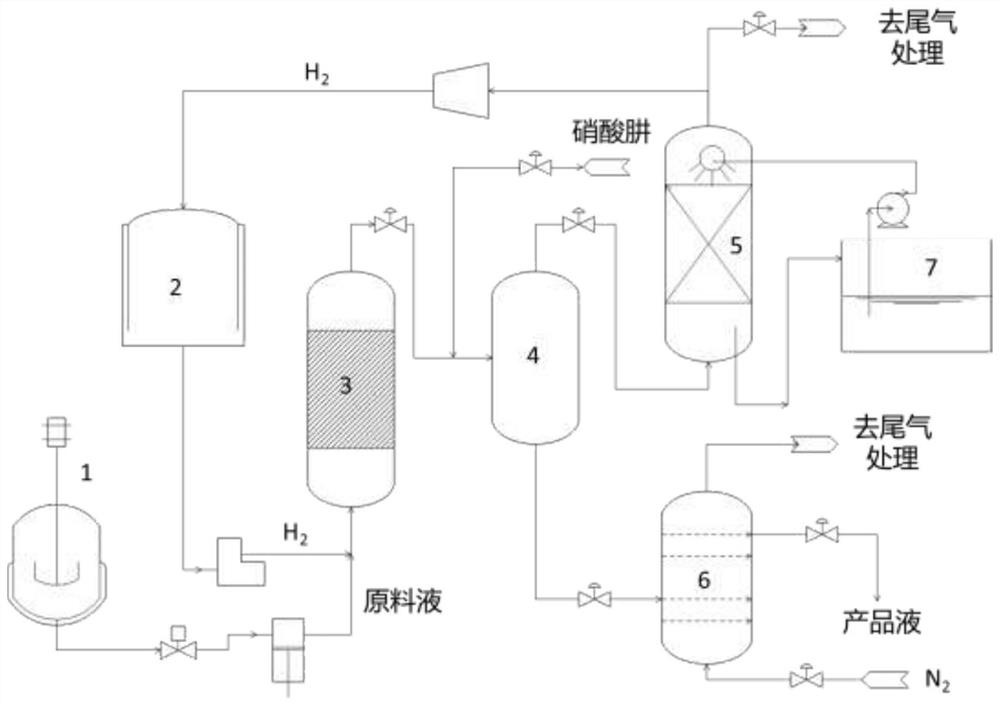

Image

Examples

Embodiment 1

[0030] The reaction liquid processing capacity is 62.5kg / h, and the UO in the raw material liquid storage tank 2 (NO 3 ) 2 The mass content is 0.31 (31%), HNO 3 The content is 0.1 (10%) and H 2The O content is 0.59 (59%), and the hexavalent uranium concentration is 208g / L; after adding hydrazine nitrate dropwise online, ensure that the final mass content of hydrazine nitrate in the high-pressure gas-liquid separation tank is 2%; the average particle size of the catalyst is 100 microns Pt / SiO 2 (1% precious metal loading). The reactor is a fluidized bed reactor. The flow rate of hydrogen is 180Nm 3 / h, the reactor temperature is 30 degrees centigrade and the pressure is 4.0Mpa (gauge pressure), the conversion rate of outlet uranyl nitrate is 98%, and the content of tetravalent uranium in the product liquid is 204g / L.

Embodiment 2

[0032] Different from Example 1 in that (the rest and the process are the same), in the raw material liquid storage tank, UO 2 (NO 3 ) 2 The mass content is 0.20 (20%), HNO 3 The content is 0.1 (10%) and H 2 The O content is 0.7 (70%), the concentration of hexavalent uranium is 134.2g / L, the conversion rate of exported uranyl nitrate is 98%, and the content of tetravalent uranium in the product liquid is 131.5g / L.

Embodiment 3

[0034] Different from Example 2 in that (the rest and the process are the same) UO in the raw material liquid storage tank 2 (NO 3 ) 2 The mass content of HNO 3 The content is 0.2 (20%) and H 2 The O content is 0.6 (60%), the concentration of hexavalent uranium is 134.2g / L, the conversion rate of exported uranyl nitrate is 98.1%, and the content of tetravalent uranium in the product liquid is 132g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com