Composite explosive particle and preparation method thereof

A technology of particles and explosives, which is applied in the field of composite explosive particles and its preparation, and composite explosives, which can solve the problems of difficulty in balancing safety and high-energy advantages, and achieve the effect of significant thermal effect, high decomposition temperature, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment provides a kind of composite explosive particles, in parts by weight, made of the following raw materials: CL-20 is 74%, ADN is 21%, composite surfactant is 1%, DOA is 1%, EVA is 3%.

[0044] The composite surfactant is composed of sodium taurodeoxycholate and nonylphenol polyoxyethylene ether in a weight ratio of 95:5 and dried.

[0045] The preparation method of the composite explosive particles of the present embodiment, the method may further comprise the steps:

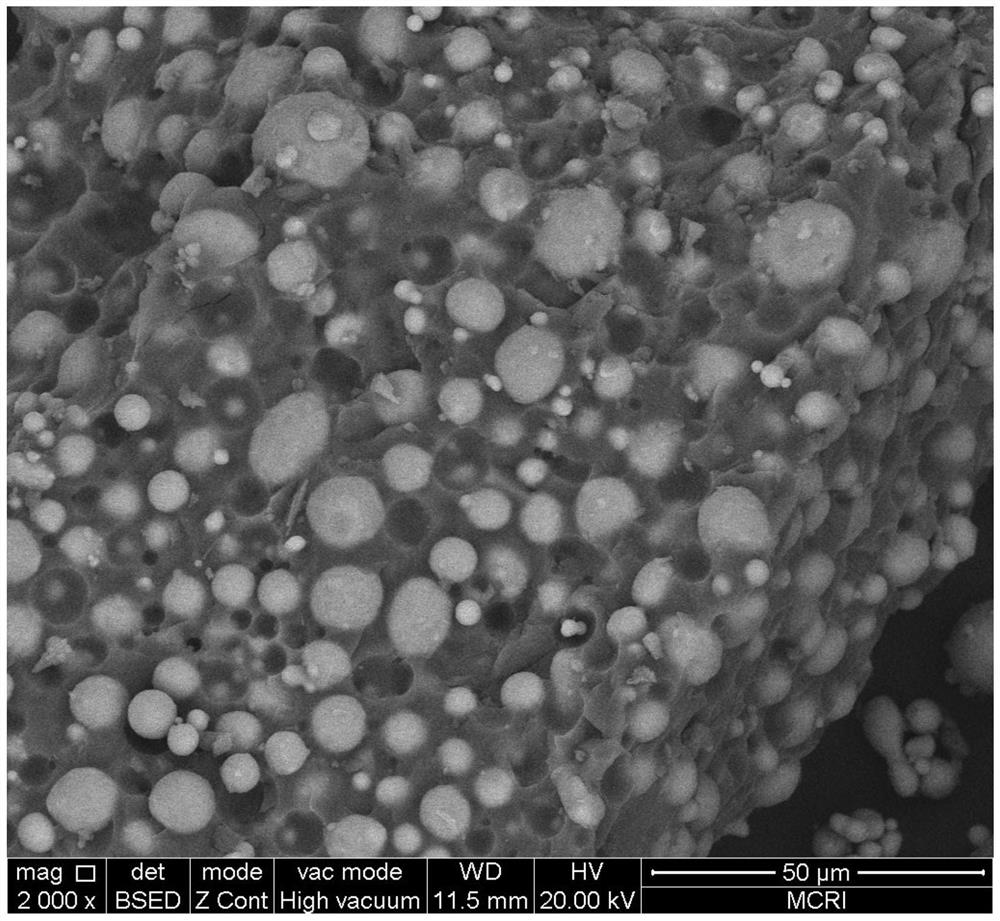

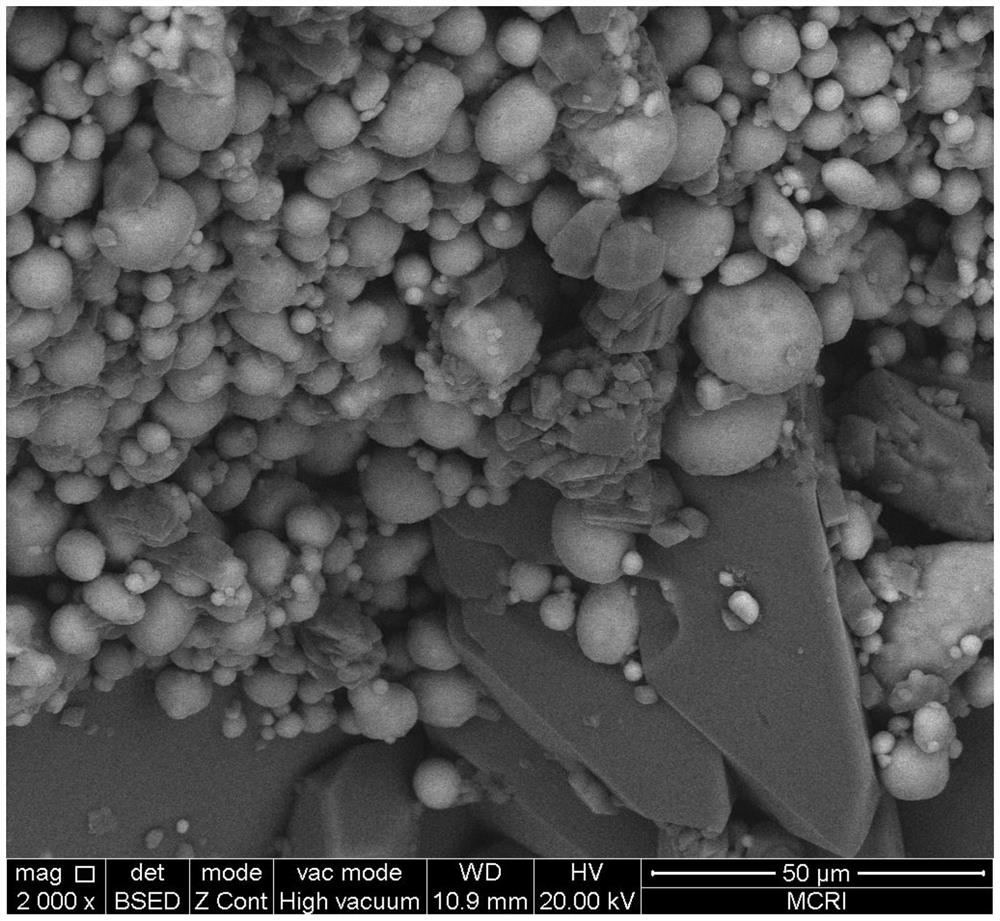

[0046] Step 1, preparation of CL-20 / ADN embedded crystal structure:

[0047] Weigh CL-2074g, ADN21g, and DOA1g; dissolve CL-20 into 500ml ethyl acetate; add ADN, control the temperature at 65-70°C, stir at a speed of 200r / min-300r / min, and add DOA after mixing for 10 minutes; Stirring speed to 60r / min, continue to stir until the material is in the form of mortar, and dry to obtain CL-20 / ADN embedded crystal structure;

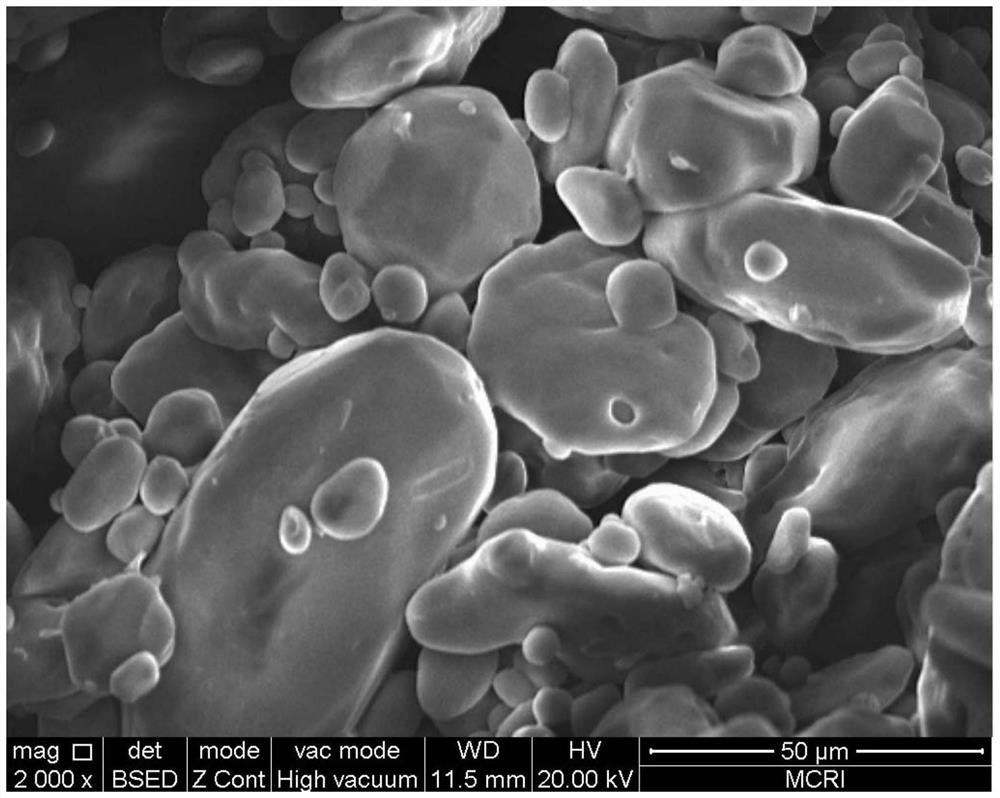

[0048]Step 2, coating embedded crystal structure:

[0049] A...

Embodiment 2

[0052] The present embodiment provides a kind of composite explosive particles, in parts by weight, made of the following raw materials: CL-20 is 72.8%, ADN is 22.2%, composite surfactant is 2%, DOA is 1%, EVA is 2%.

[0053] The composite surfactant is composed of sodium taurodeoxycholate and nonylphenol polyoxyethylene ether in a weight ratio of 95:5 and dried.

[0054] The preparation method of the composite explosive particles of this embodiment is the same as that of Embodiment 1.

[0055] See Table 1 for the performance test results of the composite explosive particles of this embodiment.

Embodiment 3

[0057] The present embodiment provides a kind of composite explosive particles, in parts by weight, made of the following raw materials: CL-20 is 74.6%, ADN is 20.4%, composite surfactant is 0.5%, DOA is 0.5%, EVA is 4%.

[0058] The composite surfactant is composed of sodium taurodeoxycholate and nonylphenol polyoxyethylene ether in a weight ratio of 95:5 and dried.

[0059] The preparation method of the composite explosive particles of this embodiment is the same as that of Embodiment 1.

[0060] See Table 1 for the performance test results of the composite explosive particles of this embodiment.

[0061] Performance Testing:

[0062] (1) According to the detonation theory of explosives, calculate the detonation parameters of the composite particles; press the composite particles into a grain column with a diameter of 20mm, and conduct the detonation velocity test according to GJB772A method 702.1, and compare it with CL-20 of 975CL-20 / 3%EVA ;

[0063] (2) According to G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com