Method for preparing explosive composite rod in local vacuum environment

A partial vacuum, composite rod technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of increasing the bonding interface strength of explosive composite rods, and the inability to bond between the base layer and the cladding material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

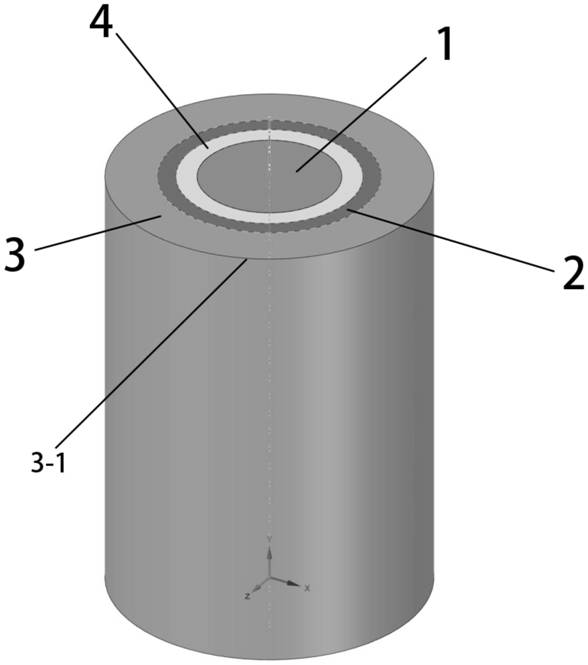

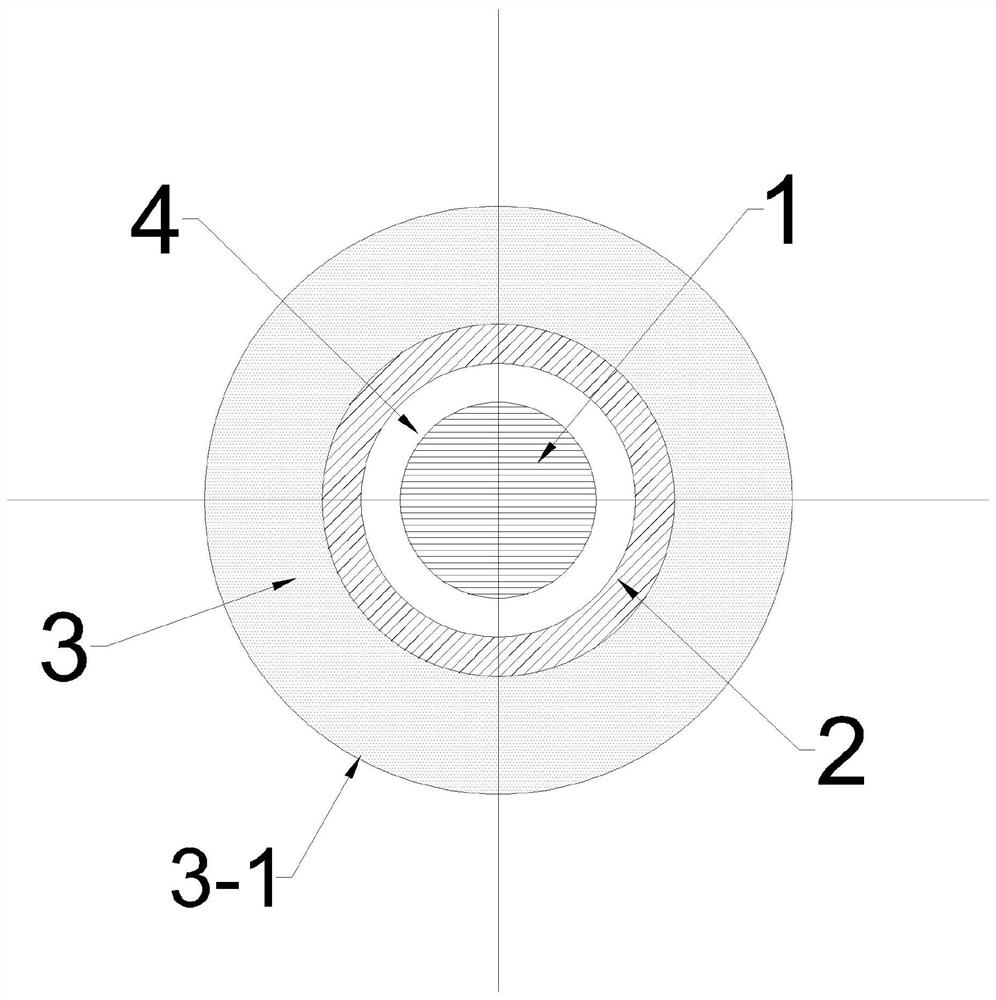

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Provided in conjunction with the accompanying drawings, a method for preparing an explosive composite rod in a partial vacuum environment comprises the following steps:

[0015] 1) Coaxially arrange the to-be-composited rod 1, the to-be-composited pipe 2, and the pvc pipe 3-1 from the inside to the outside, and fill the gap between the pvc pipe 3-1 and the to-be-composited pipe 2 with explosives and detonators to form the pipe to be welded explosive device 3;

[0016] 2) Seal and vacuum both ends of the gap between the rod to be compounded 1 and the pipe to be compounded 2 with a sealing strip to form a vacuum gap environment 4;

[0017] 3) Detonating the explosive device 3, using the high pressure generated by the explosive explosion to weld the pipe to be composited and the rod to be composited to obtain a high-quality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Section diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com