Method for preparing explosive composite tube by implosion method based on water pressure in local vacuum environment

A technology of partial vacuum and composite pipe, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., and can solve problems affecting product quality, reducing the bonding quality of materials to be welded, dust and noise pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

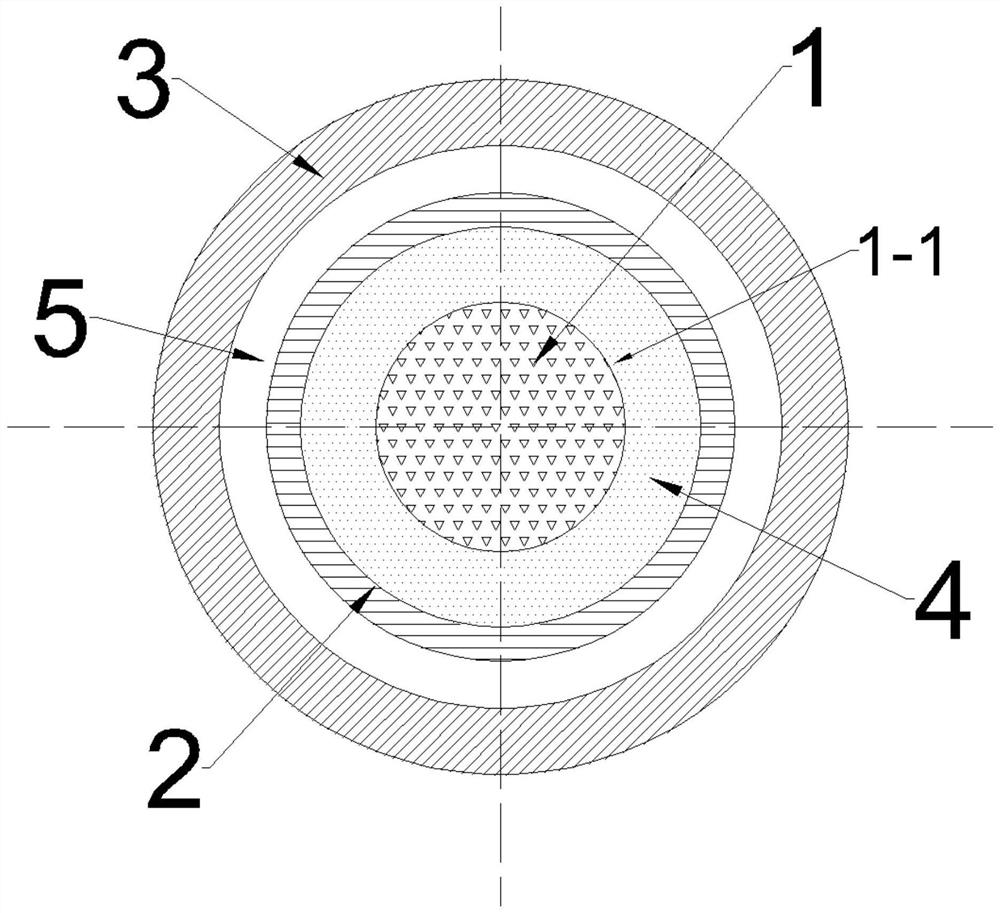

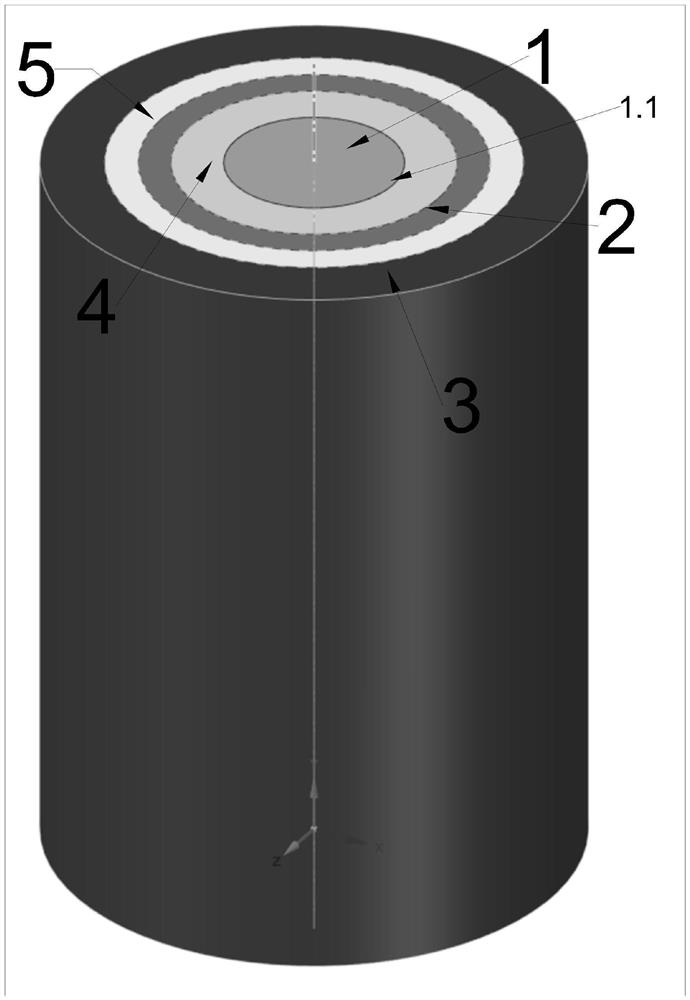

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Provided in conjunction with the accompanying drawings, a method for preparing an explosive composite pipe based on a water pressure implosion method in a partial vacuum environment includes the following steps:

[0015] 1) The pvc pipe 1-1, the metal pipe 2, and the metal pipe 3 are arranged coaxially in sequence from the inside to the outside;

[0016] 2) filling the detonator and the explosive for explosive welding in the pcv tube 1-1 to make the explosive device 1;

[0017] 3) Fill the space between the metal pipe 2 and the explosive device 1 with water to construct a water environment 4 .

[0018] 4) sealing and vacuumizing both ends of the gap between the metal pipe 2 and the metal pipe 3 with a sealing strip to form a partial vacuum environment 5;

[0019] 5) The explosive device 1 is detonated, and the metal pipes 2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com