Azido composite solid propellant containing combined stabilizer

A solid propellant and stabilizer technology, applied in the direction of non-explosive stabilizers, offensive equipment, non-explosive/non-thermal agent components, etc., can solve the problems of reduced maximum elongation and large change rate of mechanical properties, and achieve slowing down of mechanical properties. Performance change rate and effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Propellant composition

[0059] components

gaps

NG / BTTN=1 / 1

AP

RDX

Al

TPB

NPBA

mass (g)

90

180

150

400

180

0.5

2

components

TEA

stabilizer

LM-100

mass (g)

0.5

3

5

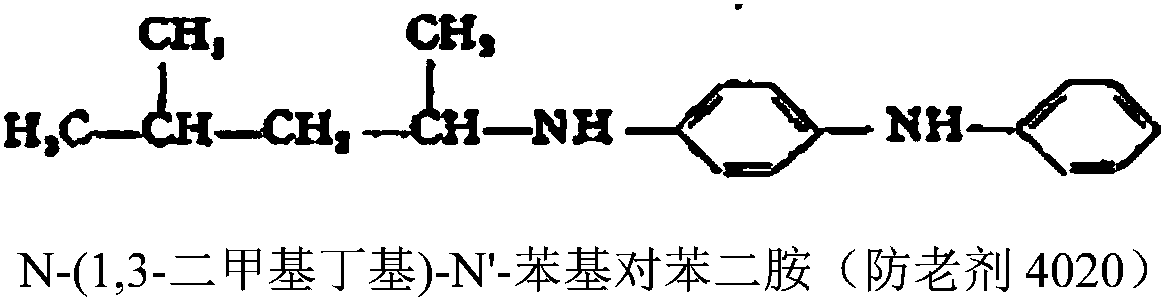

[0060] The ratio of stabilizer MNA, 2-NDPA, 4020 and carbon black N330 is 1.5:1:0.5:0.5.

[0061] (2) Mechanical properties of propellant at 70°C for three months

[0062] Mechanical properties (initial): 25℃σ m =0.90MPa, ε m =55%

[0063] Mechanical properties (70°C for three months): 25°Cσ m =0.95MPa, ε m = 50%

[0064] Maximum tensile strength (σ m ) rate of change: +6%

[0065] Maximum elongation (ε m ) rate of change: -9%

Embodiment 2

[0067] (1) Propellant composition

[0068] components

gaps

TEGDN

AP

CL-20

Al

TPB

NPBA

mass (g)

70

180

100

600

50

0.5

2

components

glycerin

stabilizer

LM-100

TDI

mass (g)

0.5

6

5

5

[0069] The ratio of stabilizer MNA, 2-NDPA, 4020 and carbon black N330 is 2.5:1.5:1:1.

[0070] (2) Mechanical properties of propellant at 70°C for three months

[0071] Mechanical properties (initial): 25℃σ m =0.84MPa, ε m =75%

[0072] Mechanical properties (70°C for three months): 25°Cσ m =0.80MPa, ε m =85%

[0073] Maximum tensile strength (σ m ) rate of change: -5%

[0074] Maximum elongation (ε m ) rate of change: +13%

Embodiment 3

[0076] (1) Propellant composition

[0077] components

gaps

TMETN

AP

CL-20

Al

TPB

NPBA

mass (g)

100

160

300

250

190

0.5

2

components

TMP

stabilizer

LM-100

MDI

mass (g)

0.7

5

5

5

[0078] The ratio of stabilizer MNA, 2-NDPA, 4020, and carbon black N330 is 2:1:0.5:1.

[0079] (2) Mechanical properties of propellant at 70°C for three months

[0080] Mechanical properties (initial): 25℃ σ m =0.85MPa, ε m =77%

[0081] Mechanical properties (three months at 70°C): σ at 25°C m =0.80MPa, ε m = 65%

[0082] Maximum tensile strength (σ m ) rate of change: -6%

[0083] Maximum elongation (ε m ) rate of change: -16%

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com