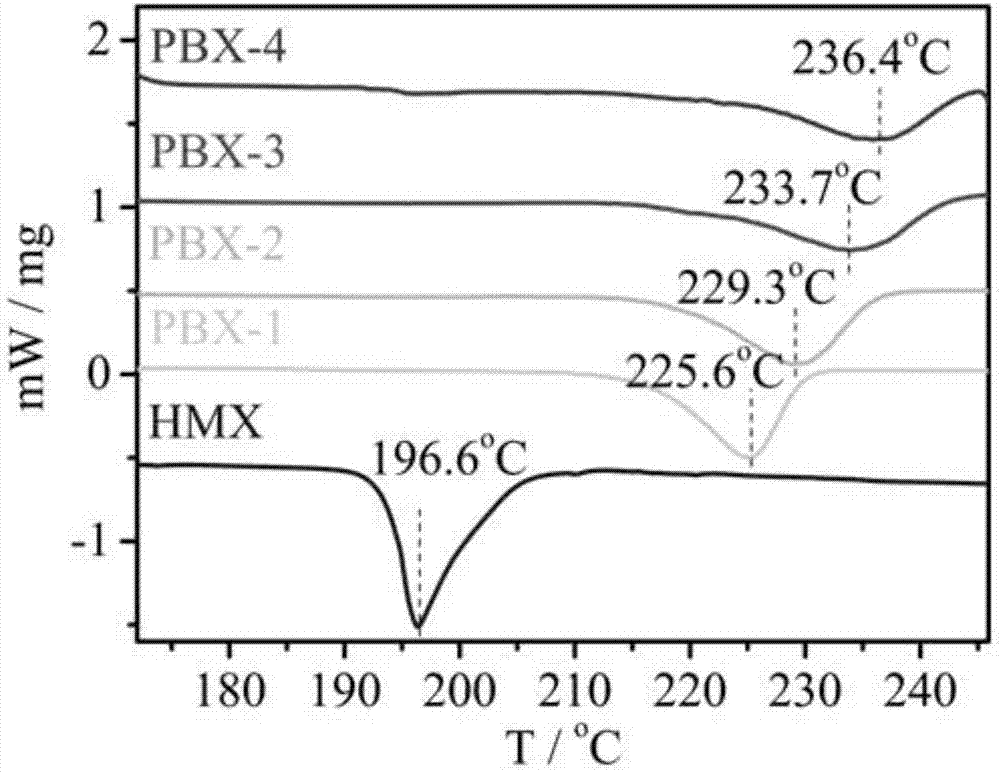

High-density heatproof octogen-based compound and preparation method thereof

An octogen and compound technology, which is applied in the field of high-density heat-resistant octogen-based composites and preparation, can solve the problem that the β→δ crystal transformation temperature is not increased enough, and the explosive compound has low density and cannot be used. Effectively improve the heat resistance of Octo and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A, Octojin pretreatment

[0036] Dissolve Tris in water to prepare a 10mM Tris solution, then add hydrochloric acid dropwise to prepare a Tris buffer solution with a pH value of 8.5; add Octogen to the Tris buffer solution, and the amount of Octogen added is 50g / L , then mechanical stirring (stirring speed: 500rpm) mixture becomes uniform octogen suspension; Blow into oxygen in octogen suspension; Dopamine hydrochloride is added in octogen suspension, the concentration of dopamine hydrochloride is 2g / L; continue to stir mechanically at room temperature (stirring rate: 500rpm) for 3 hours, filter with suction, and dry in vacuum to obtain Octogen / polydopamine. According to high-performance liquid chromatography analysis, the mass fraction of Octogen in Octogen / polydopamine accounts for 99.0%, and the mass fraction of polydopamine accounts for 1.0%.

[0037] B, Preparation of Octogenyl Complex by Slurry Method

[0038]Add 20.0 g of Octogen / polydopamine obtained through s...

Embodiment 2

[0041] A, Octojin pretreatment

[0042] Dissolve Tris in water to prepare a 20mM Tris solution, then add hydrochloric acid dropwise to prepare a Tris buffer solution with a pH value of 8.5; add Octogen to the Tris buffer solution, and the amount of Octogen added is 30g / L , then mechanical stirring (stirring speed: 500rpm) mixture becomes uniform octogen suspension; Blow into oxygen in octogen suspension; Dopamine hydrochloride is added in octogen suspension, the concentration of dopamine hydrochloride is 5g / L; after continuing mechanical stirring (stirring rate: 400rpm) at room temperature for 6 hours, suction filtration, and vacuum drying to obtain Octogen / polydopamine. According to high-performance liquid chromatography analysis, the mass fraction of Octogen in Octogen / polydopamine accounts for 97.9%, and the mass fraction of polydopamine accounts for 2.1%.

[0043] B, Preparation of Octogenyl Complex by Slurry Method

[0044] Add 20.0 g of Octogen / polydopamine obtained th...

Embodiment 3

[0047] A, Octojin pretreatment

[0048] Dissolve Tris in water to prepare a 30mM Tris solution, then add hydrochloric acid dropwise to prepare a Tris buffer solution with a pH value of 8.5; add Octogen to the Tris buffer solution, and the amount of Octogen added is 20g / L , then mechanical stirring (stirring speed: 400rpm) mixture becomes uniform octogen suspension; Blow into oxygen in octogen suspension; Dopamine hydrochloride is added in octogen suspension, the concentration of dopamine hydrochloride is 5g / L; continue to stir mechanically at room temperature (stirring rate: 300rpm) for 24 hours, filter with suction, and dry in vacuum to obtain Octogen / polydopamine. According to high-performance liquid chromatography analysis, the mass fraction of Octogen in Octogen / polydopamine accounts for 96.9%, and the mass fraction of polydopamine accounts for 3.1%.

[0049] B, Preparation of Octogenyl Complex by Slurry Method

[0050] Add 20.0 g of Octogen / polydopamine obtained through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com